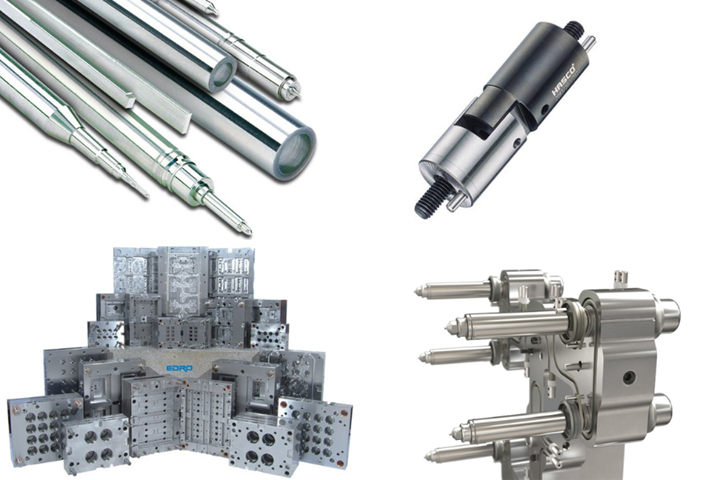

Photo Credit: (top left) Smith Enterprises, (top right) Hasco, (bottom left) Edro Engineering and Specialty Steels Inc., (bottom right) Husky Technologies.

Hot runner systems and mold components are integral to every molding operation. Advancements in the technology enable mold builders to increase their productivity, enhance molds complexity and improve operational efficiencies.

With new hot runner and mold component innovations being introduced to the market, there are an increasing number of options at mold builders’ disposal. Below, MMT has compiled recently launched products from leading technology and service suppliers. Be sure to check out MoldMaking Technology’s May 2022 print/digital issue as well to see an expanded selection of products.

For the full product post, click on each linked title, or find it under the “New Tech” section of the website.

Hot Runners

Photo Credit: Hotset America

Hotset America’s new process data logger, the D-System, is said to provide toolmakers with all of the essential measurement data required to evaluate the energy flows of the water circuits in a mold. Using various sensors, the D-System measures the amount of water, its flow and return temperatures, as well as the applied and remaining water pressure. It then calculates all relevant performance parameters relevant, such as the Delta T, a value for the energy that the mold withdraws from the water circuit or releases to it.

Photo Credit: Oerlikon HRSflow

Oerlikon HRSflow highlights its hot runner system series for small applications. Mainly suitable for engineering plastics, the S Series nozzles are said to offer a compact solution for a reduced pitch. Fast cycle time, high-production volume and quick color change factors are combined with an optimized finish for molded components. Depending on the part, they can be equipped with Sa, Tp and Sp nozzles.

DME introduces the MPC family of hot runner control systems. Designed to increase processing efficiency, the MPC’s advanced operator interface is said to decrease setup time and provide operators with exclusive tools to more efficiently and effectively troubleshoot and make process changes.

The MPC family offer reliable and precise control of a hot runner system with the simplest possible operator interface on the market, the company says. Fast control behavior reportedly makes the system universally applicable for the control of all standard systems, as well as for demanding, high-performance applications with low-mass, slim nozzles.

Mastip recently launched its liquid silicone rubber (LSR) molding solution, aiming to cater to the needs of its large customer base in automotive, medical and consumer electronics segments.

LSR molding uses the process of injecting liquid silicone material mixed with a catalyst into a heated mold, accelerating the curing cycle. Mastip says LSR injection molding has been adopted in a variety of applications due to silicone rubber’s mechanical and chemical properties such as flexibility, heat resistance and tensile strength, and is particularly useful for moldmakers facing the challenge of achieving a uniform cooling profile from the molding machine to the mold. For example, LSR is said to be an ideal material for products with specific sealing requirements such as car key housings, gaskets in automotive, respirator masks in medical devices and electronic wearables.

Photo Credit: Orycon Hot Runner Systems

Orycon Hot Runner Systems has recently added user friendly functionality to its hydraulic valve gate sequencer. The Orycon T-700-BB sequencer, with a 25" width x 60" tall footprint and 27" diameter can control 8, 16 or 24 hydraulic zones and it comes complete with oil reservoir, oil cooler, accumulator and a visual display of the timeline or screw position.

The settings can be entered via virtual keypad with accuracy of 1/10 of a second or 1/10 of 1% of the screw travel, Orycon contends. The unit is now available with direct manual controls for individual zones, making it ideal for bench testing molds as well as easing setups at the press. Pressure is adjustable up to 2,000 psi.

Photo Credit: Mold-Masters

Mold-Masters announces a significant enhancement to its advanced plastic leak detection capabilities found on TempMaster hot runner temperature controllers. Mold-Masters contends that it is the first in the industry to utilize thermal analysis to detect plastic leakage within the manifold pocket. This Manifold Leak Detection feature is expected to save molders a considerable amount of repair costs and downtime.

To enable this feature, thermocouples are installed on the manifold in various locations which are dedicated to monitoring and detecting manifold leakage. The size of the manifold will dictate how many detection thermocouples are necessary and the position of each thermocouple will determine how quickly the leakage is detected. During internal testing of this feature, Mold-Masters reported leakages were detected quickly and reliably before any damage had occurred.

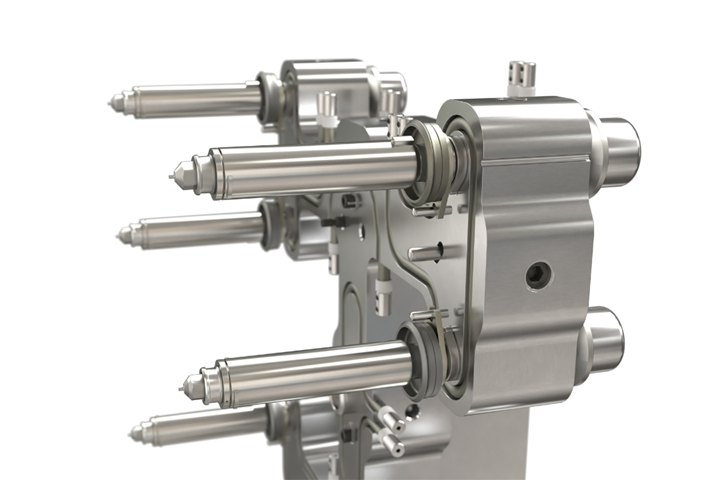

UltraMelt is Husky Technologies’ premium solution for thermally sensitive or corrosive applications which require excellent process and thermal control, with a minimal effect to the resin chemistry.

Photo Credit: Husky Technologies

The hot runner technology is suited for very small technical or medical parts made from different grades of polycarbonate, which can easily degrade at certain temperatures or residence times. These parts typically allow for minimal to no variation in surface finish, part quality or color, Husky says, and therefore must be processed with carefully designed equipment and technology. UltraMelt is also designed for bioresin applications such as polylactic acid (PLA), polyhydroxyalkanoate (PHA) and cellulose acetate (CA) which are challenging to mold due to resin chemistry.

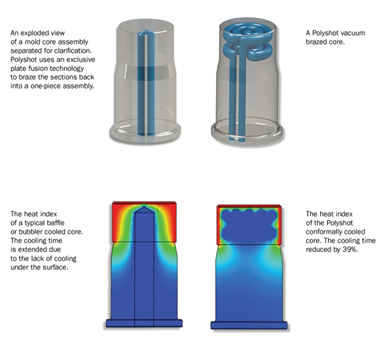

Photo Credit: Polyshot Corp.

Polyshot Corp.’s vacuum brazing services fuse multi-component mold cores and cavity assemblies for conformal cooling purposes, positively impacting mold cycle time, part quality and part repeatability.

Created with Polyshot’s Plate Fusion technology, the company says it is able to reduce cooling times in injection molds by as much as 60%. Polyshot is able to braze H13 and 420 stainless steel materials. Applications noted include mold cores and cavities in which cooling lines cannot be drilled (e.g., curved cores), high-volume production where reduced cycle times lead to higher output per machine and applications where reduced part warping results in less molded part scrap.

Photo Credit: Heitec Hot Runner Systems

Heitec Hot Runner Systems, a manufacturer of hot runner systems based in Burgwald, Germany (available in North America through Technoject Machinery), has recently provided a space-saving solution using its Flat Line Nozzles. The goal for the system was to place a direct gate on an article that has limited gate well space available and to reduce the mold base size for this 16-cavity mold.

The direct gate was made possible by the narrow profile of the Flat Nozzle 01.041.06 reaching past the protruding article detail on the cavity side. This configuration reportedly represented the ideal gate location for the article. The article, which is used in the dispensing industry, weighs about 0.5 grams. The article is molded from a 35% glass-filled polybutylene terephthalate (PBT), which the company says requires the nozzle to have an excellent thermal profile and good wear-resistant properties. In addition, the small article weight demands a low residence time to avoid degradation. The small, 2.5 mm diameter nozzle flow channels reportedly ensure an optimum residence time in the system.

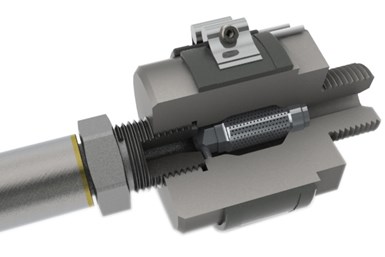

Photo Credit: INCOE Corporation

INCOE Corp. says molded part quality and superior gate cosmetics require minimal gate sizes. Any contamination in the molten plastic can plug the orifice of the hot runner nozzle gate and stop production or yield unacceptable parts. To avoid this, INCOE’s SPM filter traps foreign particles prior to entering the hot runner manifold, which the company says enables trouble-free processing and superior part quality.

The filter element design contains tapered holes to trap contaminants while enabling molten plastic flow at minimal injection pressure loss. According to the company, this minimally restricted flow through design feature is unmatched in the industry.

Single Zone MB-style bushing. Photo Credit: Melt Design Inc.

Melt Design Inc., a designer and manufacturer of hot runner systems and components, offers its internally heated Equatemp Single Zone Hot Sprue Bushings for injection molding.

Available in two styles, the solid body and the solid body with replaceable tips, the bushings are internally heated and feature a high purity ceramic insulator, replaceable thermocouple and predetermined wattage distribution, which the company says ensure the highest heat transfer rate, more accurate temperature readings and longer heater life.

With the Equatemp Single Zone or Dual Zone-style bushings, molders reportedly can gain better melt flow control for optimized quality parts shot after shot. In addition, Melt Design says the convenience of not having to do additional machining when retrofitting cold runner systems is said to save time and reduce costs.

Mold Components

Photo Credit: Fast Heat by Spark Industries

Fast Heat by Spark Industries is expanding its product line to include integrally heated sprue bushings and machine nozzles. This, says the company, enables tool shops and molders to leverage proven designs while receiving Fast Heat’s hands-on service and support. The company also offers custom mold boxes, mold and cable diagnostics, cables and Fast Heat Pulse and Ion hot runner controllers.

Integrally heated sprue bushings have a high-caliber heat transfer and can process a wide range of resins. The streamlined flow channel terminates in a reverse taper gate, providing minimum pressure loss and rapid gate freeze. The formation of a small gate stub on the part or runner results in a machine hold-time reduction, with no increase in sink marks on the part.

Photo Credit: Agathon Machine Tools

Agathon Machine Tools now offers the novel Guide System Plus, which performs guiding and centering tasks for the precise positioning of mold halves/mold component using only one system. Ideal for cleanroom, high-precision, micro-injection molding and high-temperature applications, this innovative reinterpretation of existing guiding and centering systems is said to increase planning reliability in production, boost productivity and reduce overall production costs.

By design, each bushing and pillar comes with a freely positioned retaining ring that is adjustable to various plate thicknesses for improved adaptability when repairing or converting tools to newer guide systems. One component can be used in multiple designs.

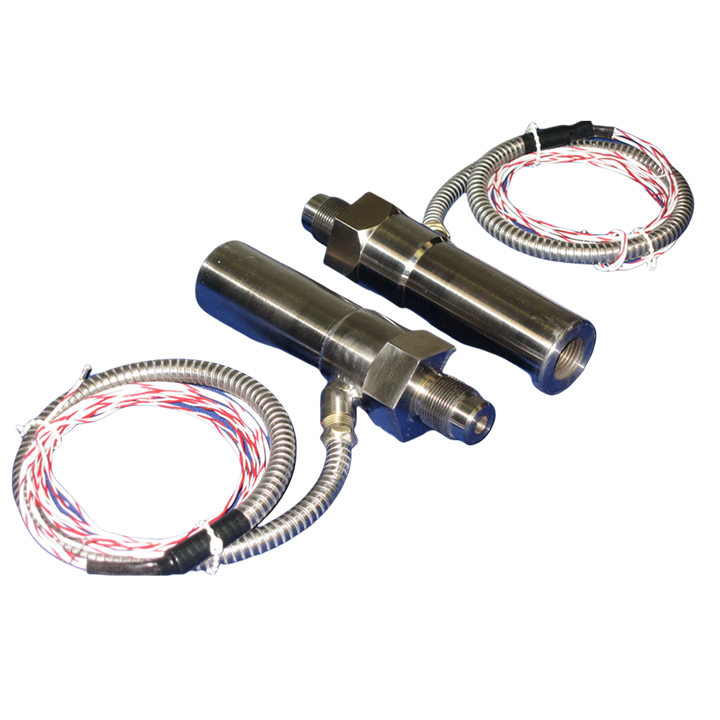

Photo Credit: Smith Enterprises

Smith Enterprises’ custom core pins expand DedTru systems grinding capacity with dimensional repeatability, accurate tolerances and concentricity within 0.001-0.0002. Ideal for demanding, small-diameter applications such as in medical and electronics, the core pins are suited for high-cavitation molds running 24/7. Consistent dimension control enables simple core pin replacement at required maintenance intervals.

With the use of double-drawn, stress-relieved M-2—which enable consistent grain structure to strength, durability, and optimized flex and deflection—Smith says its DedTru grinding is capable of holding demanding radii up to 0.0015/0.002″ and a 5-10 micro finish. Typical concentricity in multiple diameters range within 0.0002 and 0.0004. Smaller tip control down to 0.004 diameter while holding 0.0002 tolerance per diameter is achieved daily, Smith adds.

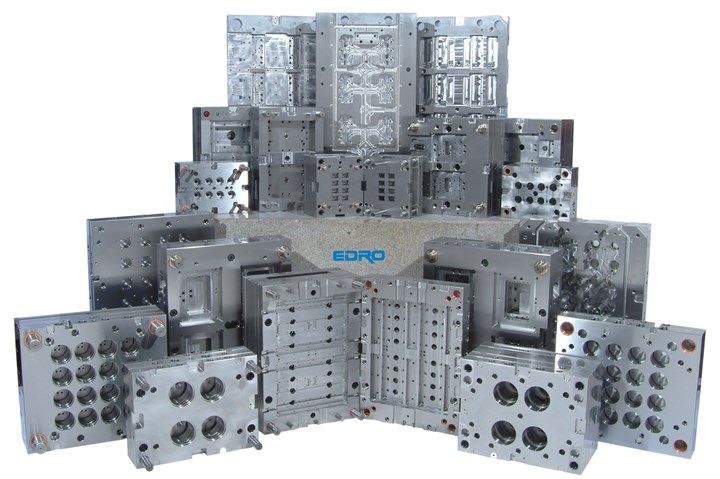

Edro Engineering and Specialty Steels Inc. showcases its specialization in the manufacture of high-cavitation custom mold bases, designed to demonstrate precision alignment and long-lasting performance. Edro primarily produces high-cavitation stripper molds, stack molds, super structures, spin-stack molds and hot runner bases, as well as auto unwind and runnerless mold bases to exacting tolerances.

Photo Credit: Edro Engineering and Specialty Steels Inc.

The company says it employes many quality control techniques to further enhance the accuracy of its work. For example, the entire finish-machining department is housed in a temperature-controlled environment to minimize plate and machine movement as final mold base tolerances are completed for product accuracy. The company also inspects all critical plates and locations in a temperature-controlled inspection room, regulated to ± 1º of the desired mark, and laser calibrates each machine on a regular basis.

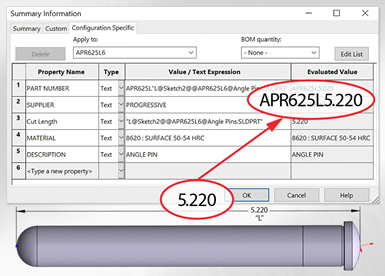

Photo Credit: Progressive Components

Progressive Components announces the release of its CADalog v14, a streamlined CAD offering for designers of injection molds. Available at no charge either online or via a flash drive, Progressive says its CADalog helps reduce redundant mold design tasks and is available in industry-standard formats for SolidWorks, NX, VISI, Parasolid, ACIS and IGES.

New to v14 are advancements geared towards simplifying custom component creation and ordering of Mold-Ready components. Mold designers who utilize the CADalog can now access a newly created SolidWorks library featuring configurable CAD geometry with populated attributes for ordering cut-to-length parts for products such as alignment locks, ejector pins and sleeves, UniLifters, angle pins, slide retainers, leader pins, bushings, support pillars and cooling items, and more.

Hasco America’s new clean-break multi-coupling system includes 21 new products with three new series; 6-, 12- and 20-point systems are available. Based on the company’s proven Z809 and Z819 systems, it allows the temperature control system to be connected in one step, removing the risk of mixing up the cooling circuits and hoses and resulting in significantly shorter setup times. Its “clean-break” feature prevents cooling fluid leakage during uncoupling. The lever locking system provides a safe and simple connection of machine and mold side.

Individual configurations as well as integration into existing systems are possible.

CUMSA continues to expand its undercuts product line by offering more demolding options. Following the double rack (DR) lifter series, CUMSA now introduces the Xtreme Double Rack (XR) lifter. The system, designed to enable a wider range of applications, comes in three different sizes and introduces four new angles: 24°, 28°, 32° and 36°.

The XR lifter facilitates the release of deeper undercuts from 31-80 mm, with draft angles from +19° up to -45° and a 100-mm ejection stroke. Mirror versions are also available to simplify the mold and the part design.

PFA Inc.’s new 70 series “mini” hydraulic locking cylinder—part of the KOR-LOK side-action system product line—features preloading capacity in a small cylinder footprint. According to the company, the U.S.-made product’s main advantages are high output force and a narrow profile. The mini’s 8,000 lbs of preload activates force in its new, narrow format, enables multiple small cores to nest together at different angles and time independently. It also features small ports and low-profile sensors, as well as zero psi locking that saves energy by dropping hydraulic pressure during injection. Further energy savings are provided by the elimination of always-on independent hydraulic core pull pumps.

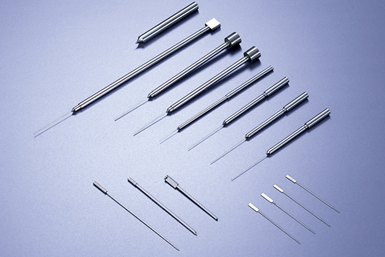

Photo Credit: Punch Industry USA Inc.

Punch Industry Co. uses five-axis equipment, CNC cutting and grinding machines, EDM and specialized equipment like Rollomatic, DedTru centerless OD/ID grinders, profile grinders, cylindrical grinders and more. Punch Industry says it is well-known for its M2 rounds with exceptional SPI or mirror finish, achieved through grinding alone. Facilities include in-house heat treating; nitriding; hard chrome, TiN and TiCN coating; and access to outside coating vendors.

Punch Industry makes metric standards and custom core pins, ejectors, blades, sleeves, thin-walled sleeves, die-cast pins, hot runner components, valve pins, locating pins and guide bushings. PET preform and caps and closure components for U.S. moldmakers and injection molders in the medical, electronics, automotive, caps and closures and other industries are also within the company’s wheelhouse.

Photo Credit: Regal Components

Regal Components Inc. has introduced a line of high-performance beryllium-free copper-based alloy core pins for high-volume, high-heat plastics molding applications. The Regal BFP type high-conductivity core pins are made from a C-18000 beryllium-free copper-based alloy providing 95-98 Rockwell B (20-25 Rockwell C) hardness. Regal says the alloy offers 10 times better heat conductivity than steel and two times better conductivity than beryllium copper pins, while also resisting thermal stress, wear and abrasion.