Build

How to Use Diffusion Bonding to Optimize a Mold’s Thermal Performance

Joining dissimilar metals has tremendous potential for conformal cooling, but to successfully use diffusion bonding, a mold builder must understand the complexities of the interface and its effect on the chemical and thermo-mechanical properties of the bond.

Read MoreHydraulic Chucks, Reduction Sleeves Reduce Toolholding Complications

Seco Tools offers a comprehensive range of hydraulic chucks and accompany reduction sleeves, eliminating risk and additional maintenance for mold and die-makers, and less required tooling.

Read MoreHow Additive Manufacturing Can Help, Not Hinder, Injection Moldability of New Designs

Four cost drivers — design for moldability, mold base size, internal componentry and polish/custom finishing — dictate the financial and processing success of a molded part design. Learn how 3D printing can assist this process, while also understanding potential pitfalls.

Read MoreJig Borer Series Meets Increasing Accuracy Needs for Molds, Castings Workpieces

J12/J16 jig borer series from Mitsui Seiki combines large capacity and high precision to process a large range of part sizes.

Read MoreMMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

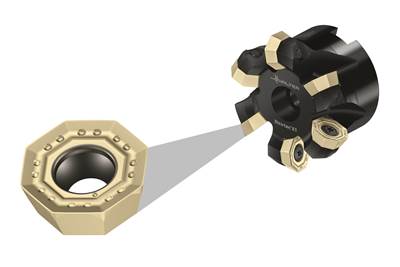

WatchCoated Grade Inserts for Machining Aluminum Alloys

The WXN15-coated grade inserts introduced by Walter USA can be used for copy milling, face milling, ramping, pocket milling and circular interpolation milling.

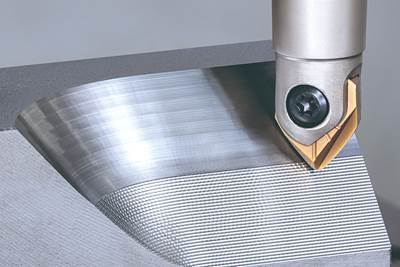

Read MoreBarrel-Style Inserts Effectively Finish Machine Complex 3D Surfaces, Intricate Profiles

Tungaloy adds five barrel-style inserts to the BallFinishNose indexable tool, improving productivity of five-axis machining contours and surfaces typical in mold and die and aerospace.

Read MorePositioning Wedges for Precision Fixing of Mold Inserts

Hasco’s new Z1855 positioning wedges enable users to change mold inserts in injection molding tools easily and lock them in place.

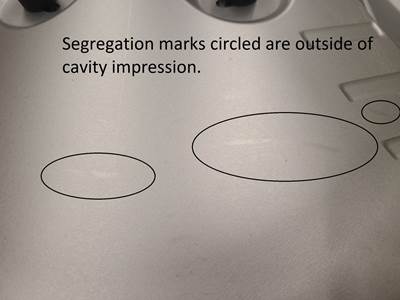

Read MoreHow to Eliminate Streaks and Weld Problems with Laser Technology

Laser technology overcomes streaking and welding challenges for new mold textures and texture repair.

Read MorePVD-Grade Carbide Milling Inserts Address Mold Machining Challenges

The new PVD grade from Walter USA is now reportedly capable of 30% greater performance in stainless steels and heat-resistant super alloys, and up to 75% greater performance in steels than comparable grades.

Read More

.jpg;maxWidth=300;quality=90)