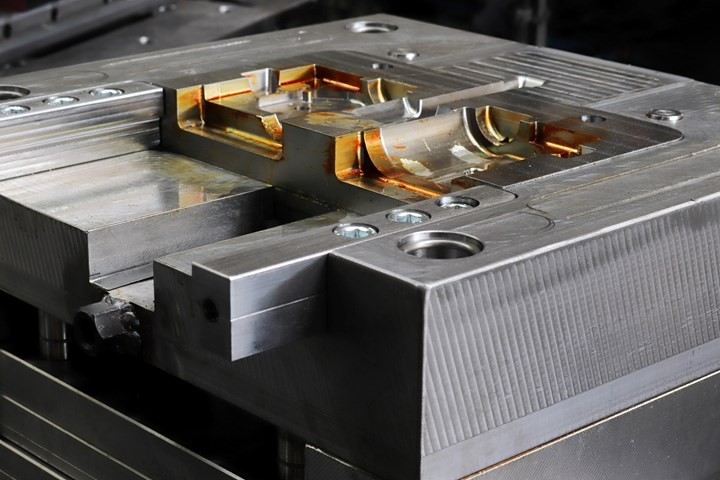

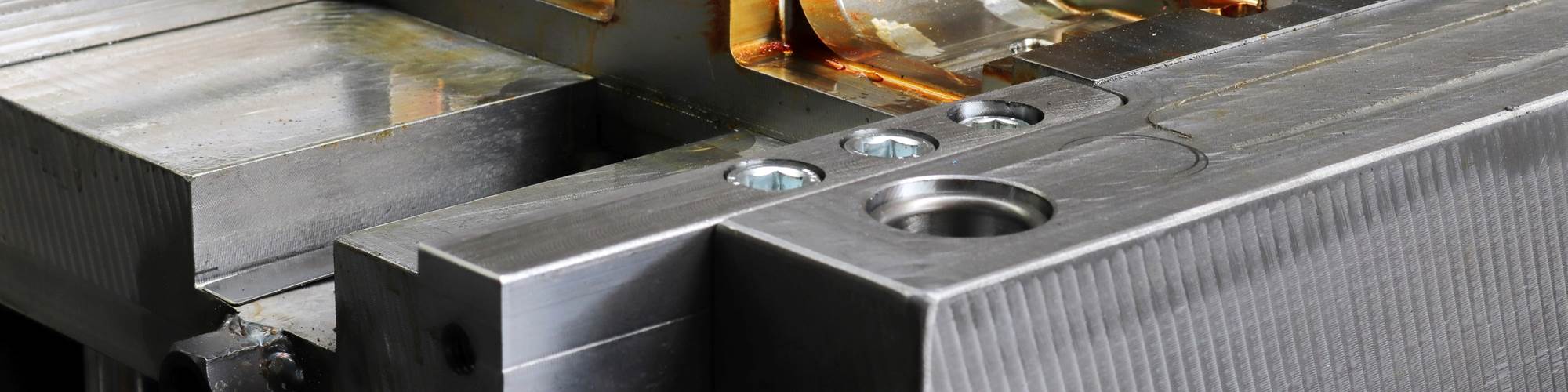

With diffusion bonding, it is not necessary to add a different material to join layers of metal for moldmaking. If a moldmaker has quality equipment, understands the processing parameters and can follow a few guidelines, its operators can manage even highly alloyed, high-temperature tooling steels. Photo Credit: Photo Credit, all images: PVA TePla America.

Mold builders can increase the quality of a finished product and reduce manufacturing costs by minimizing irregularities or imbalances in the cooling process with improved thermal performance of injection and blow molds.

The limitations of traditional cooling channel geometries and their placement are often not optimized for rapid heat extraction. Enter conformal cooling, where intricate passageways are created that closely follow the shape or profile of the mold core or cavity. With this approach, you can inject melted resins more rapidly and at higher pressures, significantly decreasing cycle times, increasing throughput and improving product quality.

To achieve high-quality engineered plastic components, the mold must use a uniform thermal distribution pattern, which requires the coolant channels (or heating elements) to be very near the mold’s edge and mirror the component’s geometry.

Although the benefits of conformal cooling are established, the larger question is how to achieve this result in the most efficient, effective moldmaking approach possible. To date, there has been little consensus on the best approach for cooling channel design.

Diffusion bonding can more efficiently join multiple layers of high temperature-resistant tool steels, as well as stainless steel, without brazing material. Once the die layers are bonded, traditional machining can then be used to create the final external shape.

Brazing Barriers

Mold builders have machined cooling channels into molds in straight lines for many years. When more intricate channels were required, they could make the mold in multiple layers with pre-machined channels and then braze them into a final assembly.

Brazing is a metal-joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint. The filler metal flows into the gap between the layers through capillary action. Although brazing can be used to join similar or dissimilar metals with considerable strength, it has drawbacks when internal passageways are involved. For example, brazing can cause small “fillets” to form in the passageways that obstruct flow and break off during use.

Brazing alloys typically used with tool steel molds are nickel-based, which can lead to a variation in thermal performance that make it difficult to provide temperature uniformity across intricate or delicate polymer-based components during processing.

Diffusion bonding is an alternative to making complex molds, as this process efficiently joins multiple layers of high temperature-resistant tool steels and stainless steel without brazing material. Moreover, it is not necessary to add a different material to join the layers, and one ends up with a mold optimized for thermal performance.

Although the benefits of conformal cooling are established, the larger question is how to achieve this result in the most efficient, effective moldmaking approach possible.

Diffusion Bonding

For many years, manufacturers have used diffusion bonding to join high-strength and refractory metals that are either difficult or impossible to do so by other means. The process—which involves applying high temperature and pressure to similar or dissimilar metals mated together in a hot press—causes the atoms on solid metallic surfaces to intersperse and bond. Due to the molecular bonding of the layers, the final part often shows no interface lines or striations, as the interface of one material is blended into the other one, and vice versa, even with dissimilar materials.

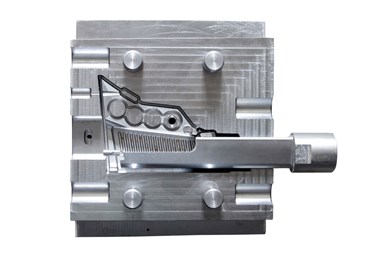

In addition, this technique allows moldmakers to build molds from the ground up using thin 1-2-millimeter metal and alloy sheets, as well as map out sophisticated internal channels or passageways with 3D modeling software before cutting each layer. A mold builder can incorporate more complex cooling channels into injection or blow molds using a multilayer design, for example, enabling high pressures. Once the mold layers are bonded, the final external shape can be machined.

3D printing is also being used to create conformal cooling channels. Although this approach accomplishes similar results, 3D metal-printed parts are limited in size and struggle with yielding a high-quality surface finish on machined channels and finished parts. Diffusion bonding produces finished molds that have an external geometry as large as 900 millimeters (35.43 inches) x 1,250 millimeters (49.21 inches) x 500 millimeters (19.69 inches), including smaller molds in batches.

Advances in Diffusion Bonding Equipment

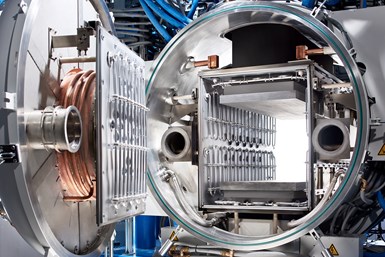

Advances in high vacuum hot presses enable superior pressure control and rapid cooling systems to improve the bond, increase yields and significantly decrease cycle time.

For example, in the case of the pressure applied, integrated, single-cylinder hydraulic presses can apply a consistent, measurable amount of force. However, this provides very little control over large parts with more complex geometries. To improve force distribution, thick graphite pressing plates (10-15 inches in height) mate the metal layers together at a more consistent pressure. Unfortunately, this takes up furnace space while adding to the time to heat the surfaces of the metals.

A mold builder can incorporate more complex cooling channels into injection or blow molds using a multilayer design, for example, enabling high pressures.

Multi-cylinder systems with large pressing plates as large as 900 millimeters (35.43 inches) x 1,250 millimeters (49.21 inches) can accommodate various parts and process substrates. The pressing force is 4,000 kilonewtons. Research is underway to increase the geometrical limitation.

The integrated press provides consistent pressure across the entire surface by controlling each cylinder independently. Such a system also comes with built-in pressure transducers along the bottom of the pressing plate. In addition, you can adjust the individual hydraulic cylinders with the software to achieve uniformity over large areas based on sensor feedback.

Although tool steel is designed to be used at high temperatures, it can still be bonded this way when using the proper equipment. If a mold builder has quality equipment, understands the processing parameters and follows a few guidelines, the team can manage even highly alloyed, high-temperature tool steels.

Tool steels can be bonded with a diffusion bonding process when you use the proper equipment, even with tool steels that are designed to be used at high temperatures.

This process is able able to bond different tool steels to reduce costs. For example, on the surface that the parts touch, a mold builder might use a high-value, temperature- and corrosion-resistant tool steel with good thermal conduction and less expensive steel on the reverse side as the support.

To ensure the quality of the diffusion-bonded interface during design and development, analyze samples with non-destructive inspection (NDI) techniques, such as scanning acoustic microscopy or scanning electron microscopy/energy-dispersive X-ray spectroscopy. Then, destructively analyze trial samples and fabricate them into standard mechanical test specimens to collect repeatable data.

You can use diffusion bonding to bond different tool steels to reduce costs.

Exploring Diffusion Bonding

To successfully use diffusion bonding, you must understand the complexities of the interface and its effect on the chemical and thermo-mechanical properties of the bond. However, with the industry’s traditional focus on machining and brazing, formal education on diffusion bonding has been minimal.

Combining the beneficial properties of different metals is the main reason to explore diffusion bonding. However, many manufacturers do not understand how to design, prepare or handle the parts. Plus, they have questions about process data and require guidance on heating, cooling and pressing rates.

In such cases, consulting with an expert manufacturing partner is the quickest way to consider the possible benefits of diffusion bonding and identify the best approach to take to tailor diffusion bonding to the manufacturer’s process cost-effectively.

Related Content

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

How to Improve Melt Distribution with Diffusion-Bonded Manifolds

Diffusion bonding for manifold manufacturing offers design freedom for optimizing hot runner melt distribution, reducing color change-over time, cavity-to-cavity weight variation, peak injection pressures, melt degradation, and resin flow stress.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)