Coated Grade Inserts for Machining Aluminum Alloys

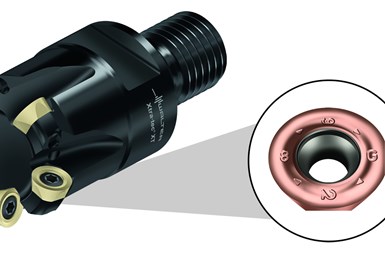

The WXN15-coated grade inserts introduced by Walter USA can be used for copy milling, face milling, ramping, pocket milling and circular interpolation milling.

Walter USA launches the WXN15-coated grade for machining ISO N materials. Walter says it is responding to the growing use of aluminum in the automotive and aerospace industries, as well as in general metalworking where it can increase machining speeds in a range of applications. Aluminum alloys are also highly versatile materials for mold manufacturing.

The WXN15-coated grade inserts are introduced with a highly positive shaped geometry, which is effective in machining ISO N materials. When used in advanced cutter bodies like the new Xtra·tec XT M5468 button insert milling cutter with G88 geometry, Walter says productivity is increased when performing machining operations on deep shoulders with excellent chip removal.

The inserts are available in 77 varieties of insert shapes, sizes and varying geometries to fit all of the most popular Walter milling families. WXN15-coated grade inserts can be used for copy milling, face milling, ramping, pocket milling and circular interpolation milling.

Though engineered for aluminum machining, most inserts of this WXN15-coated grade are said to be effective on other non-ferrous materials, as well as some steels, stainless steels, cast iron and even materials with difficult cutting properties, including hard machining.

Related Content

-

Roughing, Finishing Aluminum-Specific End Mill Line Expansion

Extended range of Sandvik Coromant’s CoroMill Dura versatile solid end mills engages stable cutting, small burr, good surfaces and minimal vibration.

-

Aluminum Machining Efficiency Improved With Milling Inserts

The TungAluMill line has been enhanced with 10 new XVCT-AM inserts, featuring an interface design that augments machining at high speed rates.

-

How is an Aluminum Mold Energy-Efficient?

Nine ways aluminum molds save energy and production costs.

.png;maxWidth=300;quality=90)