Build

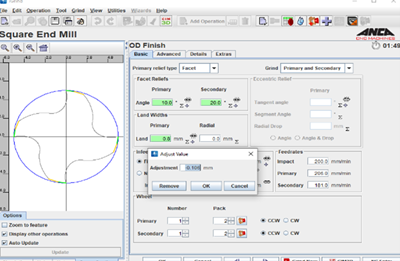

Cutting Tool Measurement, Compensation Expands to Meet Tool Needs

Zoller’s measurement machines and ANCA software easily communicate to simplify and improve tool measurement, wheel measurement, form measurement and compensation processes.

Read MoreNew App for Moldmakers Adds Functions, Part Scanner

Hasco’s new app has a number of new and augmented functions including an NFC (near-field communication) scan for reliable identification of original Hasco products.

Read MoreVMC Provides Shorter Cycle Times, Minimizes Non-Cutting Time

The SVM 5100L joins DN Solutions' vertical machining center lineup for die-cast components.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

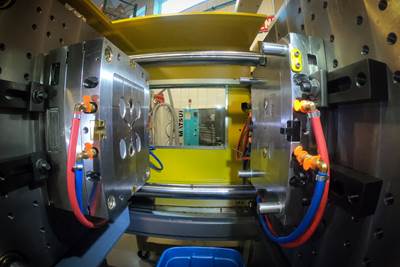

Read MoreNew Temperature Controller, Hot Runner for Micro Molders

Günther unveiled a new hot runner temperature controller and a specialized hot runner built specifically for the Babyplast line of molding machines at K 2022.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

WatchMachine Tool Breakage Detector Enhances Mold Manufacturing Reliability

Heidenhain’s new TD 110 is a fast, contact-free, in-process gage that can quickly inspect drill bits and end mills, even while spinning at their operational speed.

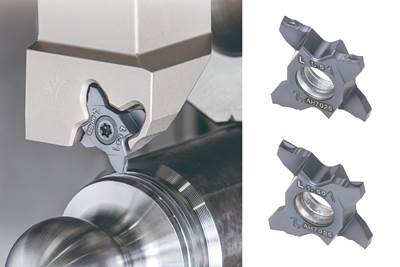

Read MoreLeft-Hand Cutting Tools Increase Multitasking Machine Productivity

With multitasking machines gaining popularity across manufacturers, including moldmakers, the expansion of Tungaloy’s TetraMiniCut’s ensures simultaneous machining on the left- and right-hand spindles of such machines.

Read MoreFrom Machining Centers to Cutting Tools: Here are the Top Ten Case Studies from 2022

MMT publishes monthly case studies that present a shop’s problem, solution and results in thorough detail. Take a look at the top ten most popular case studies published in 2022 based on Google Analytics.

Read MoreHigh-Feed Milling System Optimizes Mold Milling Operations

Easily tackle challenging ISO P, M and S materials with the next-generation Seco High Feed SP milling systems, featuring dedicated cutting geometries and insert grades.

Read More

.jpg;maxWidth=300;quality=90)