Build

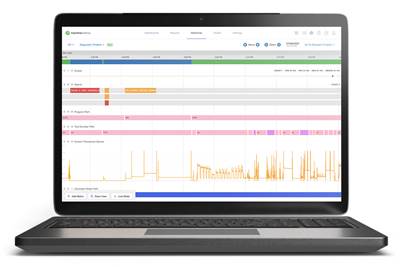

Automatic Robot Performance Monitoring in the Mold Shop

Precision manufacturers can now monitor collaborative robots from Universal Robots in real-time to drive automation that improves performance and reliability.

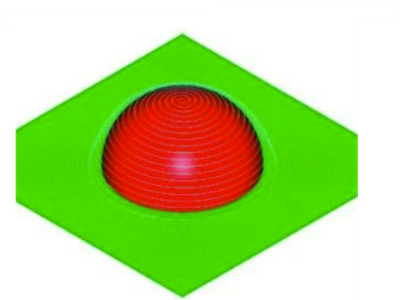

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreMicro-Diameter End Mill Series Reduces Cutting Time, Enhances Finishing for Ultra-Precision Moldmaking

Towa Corp. features CBN and proprietary-coated solid carbide end mills that feature high accuracy, optimized sharpness and wear resistance and ensure long tool life.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MorePCS Company Now Distributing i-mold Tunnel Gate Inserts in the US

Mold component product enables automatic degating of plastic parts from hot runners during ejection.

WatchNew Slide Design With Floating Insert Supports Mold Simplification

CUMSA’s new slide concept is free to move horizontally and vertically, optimizing design, installation and maintenance simplicity for mold builders and molders.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

WatchAccumold Invests in Micro AM Capability

The purchase of a second Fabrica 2.0 machine compliments Accumold’s existing micro mold technologies and services, driving continuous, disruptive innovation for customers.

Read MoreMold Component Supplier Offerings Enhance Moldmaking Capabilities

Punch Industry USA supports American mold builders, injection molders and manufacturers with a variety of off-the-shelf and custom components that enable more time for mold shops to build molds.

Read More

.jpg;maxWidth=300;quality=90)