Build

Five-Axis CNC is Ideally Suited for Solid PCD End Mill, Drill Production

The ANCA EDGe machine is capable of creating complex 3D cutting tool forms, including the company’s new generation of solid PCD helical end mills and drills.

Read MoreMulti-cavity Hot Runner Design Takes on Bio-based Material Challenges

Mold builder teams up with a hot runner supplier to develop a system configuration that produces an eco-friendly, attractive single-serving capsule.

Read MoreAdvances in P20 Steel Potentially Eliminates Need for Stress Relieving After Rough Cutting

Omega Tool Corp. compares conventional, new P20 grades side by side in production fascia tools, finds no downside.

Read MoreSolid Carbide Cutters Ensure Smooth, Dynamic Milling Operations

Walter’s MD173 and MD177 Supreme solid carbide milling cutters feature seven cutting edges.

Read MoreHow to Machine Micron-Level Precision Molds in One Try

On-machine measurement intelligence and modification technology helps mold builders overcome machining variables and quickly produce micron-level tolerances.

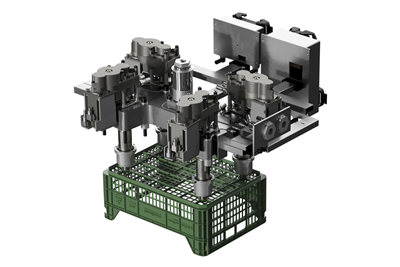

Read MoreOptimized Hot Runner Systems for PCR Compounds

Hot runner systems manufacturer Oerlikon HRSflow is developing new hot runner solutions to help create new products including fruit crates and home composting buckets.

Read MoreNew Tool Breakage Alarm System Mitigates Machining Damage

If a cutting tool breaks or compressor malfunctions the Tool Breakage Alarm from Air Turbine Tools alerts operators, or stops the program altogether.

Read MoreNoncontact Tactile Measurement Tool Advances Moldmaking Equipment

The Laser Contour Check from Walter, a brand of United Grinding, combines a blue laser and intelligent measuring system to accurately measure tool parameters on grinding and eroding machines.

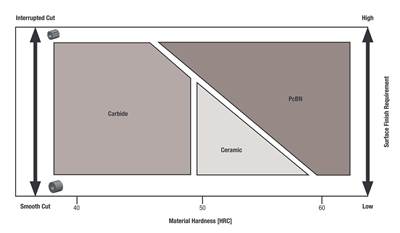

Read MoreCeramic Grade Increases Productivity When Machining Hardened Steels, High-Temp Alloys, Cast Irons

Higher wear resistance and longer tool life in hard turning applications up to 58 HRC with Kennametal’s KYHK15B grade.

Read MoreFive Ways a Hot Runner Is Key to Processing Reinforced Materials

A trusted hot runner supplier should work closely with mold builders and molders to manage the expectations (and realities) of supporting the specification, tool design, installation and service of a hot runner system.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)