From machining centers to cutting tools and everything in between, here are the top ten case studies published by MoldMaking Technology in 2022 based on analytics.

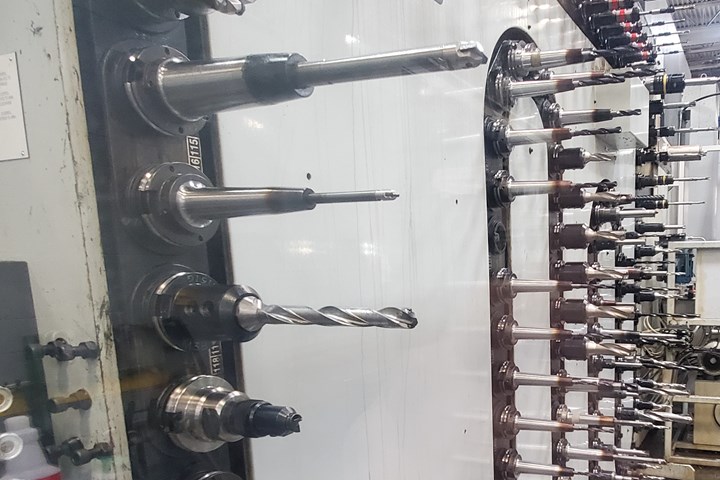

10. Workhorse Shrink-Fit Machines Yield Repeatability

Omega Tool Inc. switched to a toolholder/shrink fit system for better quality, improved repeatability and longer cutter life for its ultra-precise mold machining.

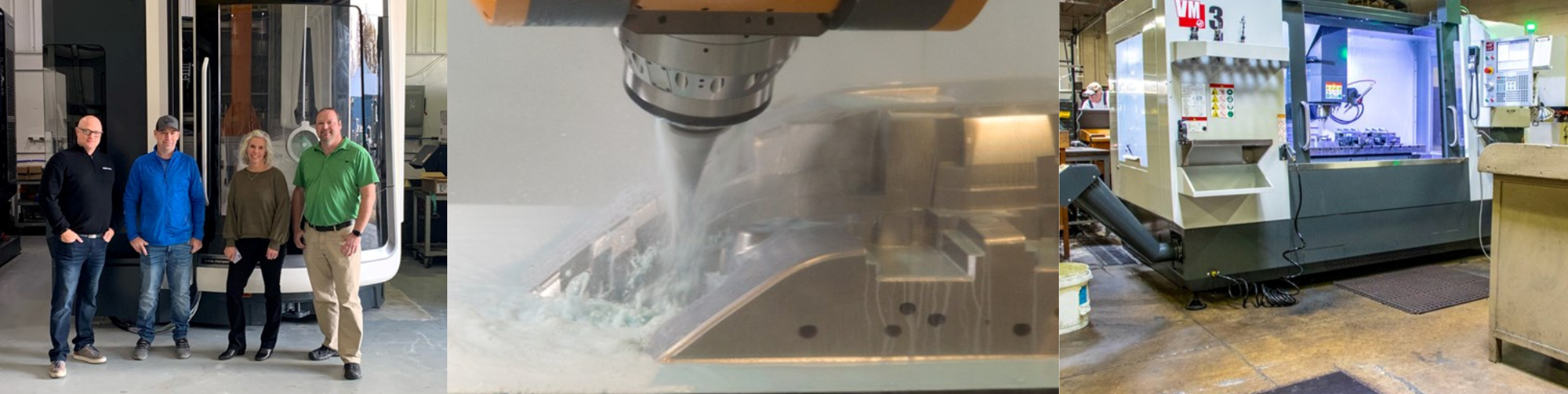

9. Hybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

8. Quickly Troubleshoot New Molding Defect with Moldfilling Software

SyBridge Technologies analyst compares original, new Moldflow process simulation results, solves molding defect without tool needing to be taken out of production.

7. Mold Builder Gains Higher Accuracy, Repeatability, Productivity from Milling Machine

Very high stability, precision, thermal and vibrational control, and low cost of ownership led Diamond Tool & Engineering to purchase a high-precision, high-speed three-axis milling center.

6. Helping High-Precision, Multiaxis CNC Machines Maintain Tight-Tolerance Control

Standardizing Heidenhain control systems on multiaxis CNC machines across the shop floor help Cavalier Tool streamline setups and post-process work, increase accuracy, and improve turnaround and scheduling flexibility to maintain its competitive edge.

5. Speed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

4. Vertical Machining Center Designed for Moldmaking Alongside Metal 3D Printers Brings Virus Face Masks to Market Quickly

Speed and accuracy of a new vertical machining center are vital to a two-process approach for quickly producing much-needed face mask molds.

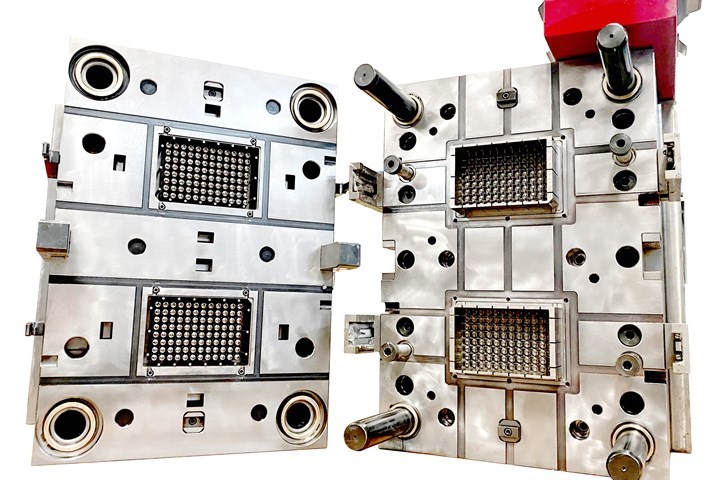

3. Compact Mold Components are Critical to Keep Connector Program Cost-Competitive in North America

Molded Precision Components relied on Heitec compact hot runner, valve gate systems to enable a mold to fit in small press’ limited daylight opening.

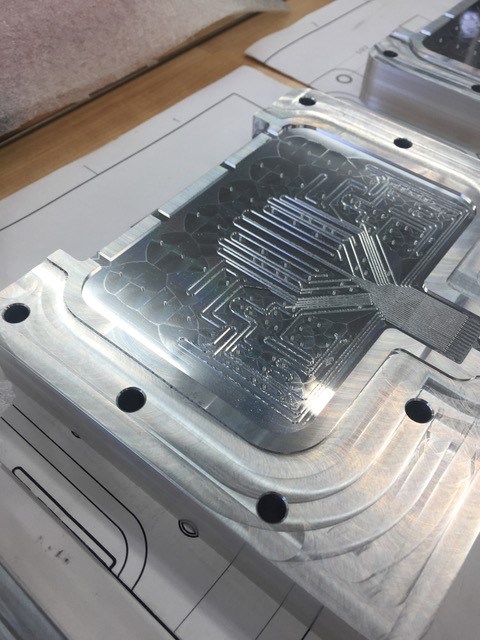

2. Control Helps Push the Limits of Five-Axis Micro Mold Machining Accuracy

Toolmaker quickly meets the demands of critical medical device manufacturers with a new five-axis machine tool equipped with the right control technology.

Photo Credit: M5

1. Hot Runner, Mold Component Partnerships Lead to Innovative Mold Designs

Formula Plastics takes on tooling via sister company Formula Tooling using dedicated partners, 3D modeling services and highly trained engineers to develop advanced mold designs.

For more case studies from MoldMakingTechnology, click here.

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

.png;maxWidth=300;quality=90)