Left-Hand Cutting Tools Increase Multitasking Machine Productivity

With multitasking machines gaining popularity across manufacturers, including moldmakers, the expansion of Tungaloy’s TetraMiniCut’s ensures simultaneous machining on the left- and right-hand spindles of such machines.

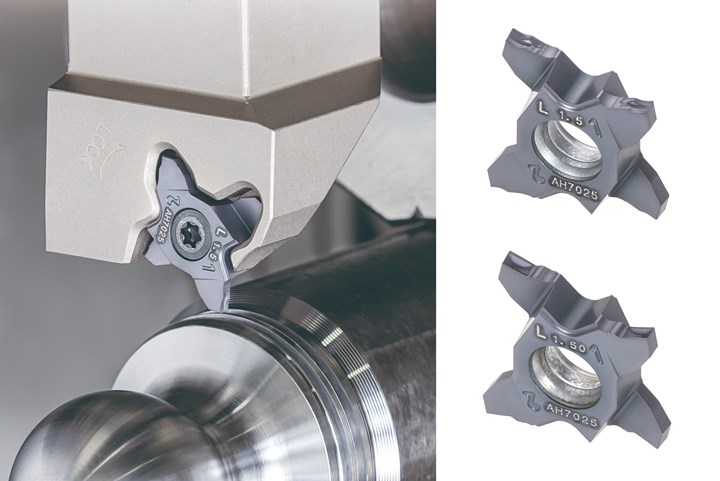

Machining centers that can handle multiple tasks like deep-hole drilling and complex machining continue to be integrated into moldmaking shops to further mold manufacturing capabilities and efficiencies. The 37 left-hand inserts newly added to Tungaloy America’s TCS18 and TCL18 insert lines of the TetraMiniCut grooving and parting tool series targeting multitasking machines, have the potential to further this agenda.

Featuring parting and grooving inserts with four economical cutting edges, TetraMiniCut offers an insert clamping method that ensures secure retention and high edge repeatability, promising machining accuracy and tool life predictability.

The series’ TCS18 and TCL18 inserts designed for left-hand cuts expand the product lines that, up to now, have offered right-hand inserts only. Grooving and parting tools commonly used in most of the operations performed in conventional CNC lathes and Swiss machines are right-handed. As highly advanced multitasking machines with multiple spindles and turrets are gaining popularity to maximize productivity, the needs for left-hand tools are increasing as well, which enable simultaneous machining on the right- and left-hand spindles of such machines.

TetraMiniCut’s TCS18 and TCL18 geometries feature pressed-to-form 3D chipbreaker that are said to provide high chip control. TCS18 incorporates four cutting edges with an optimal rake angle that provides the cutting edge with a good balance of strength and sharpness. TCL18 has cutting edges with a large rake angle that generates light cutting action and reduced cutting load for machining stability.

With this expansion, TetraMiniCut left-hand tooling can now be purchased off the shelf at less costs, while enabling more end users to use the full capabilities of TetraMiniCut’s tool stability, accurate edge repeatability and maximum productivity over an expanded range of grooving and parting operations.

Related Content

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

.png;maxWidth=300;quality=90)