Build

Vacuum Brazing Meets Additive Manufacturing for Optimized Conformal Cooling

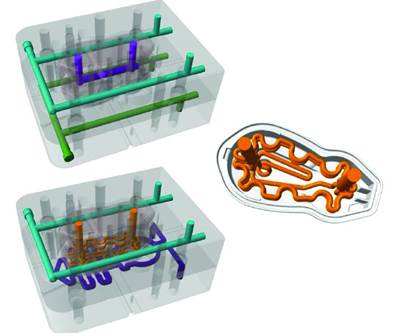

Renishaw and Liechtenstein-based Listemann Technology have joined forces to service moldmakers with the optimum conformal cooling solution. Depending on the application and desired reduction in cycle time, the companies now jointly design and create conformal cooling channels either through vacuum brazing, laser sintering or a combination of both to find the most suitable and cost-efficient design for their customers.

Read MoreTechnology Tuesday: EDM Success

Cruise through this week’s Technology Tuesday slideshow to see EDM units that shops across the country have used to increase capacity and leverage greater efficiency in their processes.

Read MoreTurning Center Has Stiffness and Rigidity for Heavy Cutting

The SL8-II has robust roller guideways and six roller bearings for accuracy and heavy cutting.

Read MoreSLM Launches Updated AM Resources Website

The company has posted an updated site on the selective laser melting process.

Read MoreSlim Toolholder Precisely Machines Areas That are Difficult to Reach

The Tribos-SVL from Schunk is combinable with a variety of toolholders for versatility.

Read MoreFlat Ejectors Have Tight Dimensional Tolerances for Flash-Free Production

Flat ejectors Z4656 and Z4655 from Hasco have either two or four corner radii over the full length of the ejector blade.

Read MoreTake a Look Inside Deep Hole Drilling

Do I have your attention with this shot? It’s the inside of a gun barrel. What does that have to do with moldmaking? More than you think when it comes to deep hole drilling your waterlines, cross hole drilling, and deep pockets at compound angles, and on one machine instead of three—boring, five-axis machining and deep hole drilling in one accurate yet approachable machine.

Read MoreEDM Machine Has Power Optimizer to Reduce Machining Time

The Edge2 EDM machine from Makino incorporates SuperSpark4 and Intelligent Expert System technology for increased accuracy and efficiency.

Read MoreLessons Learned in Deep Hole Drilling

Of course when it comes to deep hole drilling, the tooling, the fixturing and the automation are all essential, but the part that caught my attention during a recent UNISIG event was the focus on mold-specific industry solutions, especially its USC-M series machines that allow multiple operations to be performed on all workpiece sides with one setup.

Read MoreCompact EDM Machine Has Varied Features for Accuracy and Ease of Use

GF Machining Solutions’ new compact Form E 350 machine has a generator for quality surface finishes and precision applications in any conductive material.

Read More