Vacuum Brazing Meets Additive Manufacturing for Optimized Conformal Cooling

Renishaw and Liechtenstein-based Listemann Technology have joined forces to service moldmakers with the optimum conformal cooling solution. Depending on the application and desired reduction in cycle time, the companies now jointly design and create conformal cooling channels either through vacuum brazing, laser sintering or a combination of both to find the most suitable and cost-efficient design for their customers.

Share

Liechtenstein is a micro-state located between Switzerland and Austria. It is the fourth smallest country in the world. The nation is known for being a tax haven that holding companies and financial services enjoy. “However, around 40 percent of the workforce is employed in the industrial sector,” Manfred Boretius, CEO of Liechtenstein-based Listemann Technology, says.

Listemann was founded in 1990, and it has grown to become one of the leading suppliers of thermal processing including heat treatment, brazing, electron-beam welding, sintering and engineering services. Among other things, the company specializes in supporting moldmakers with the manufacturing of injection molds with conformal cooling channels, which optimize heat dissipation to decrease cycle times in injection molding operations.

Fusing Multi-Component Mold Cores, Cavity Assemblies

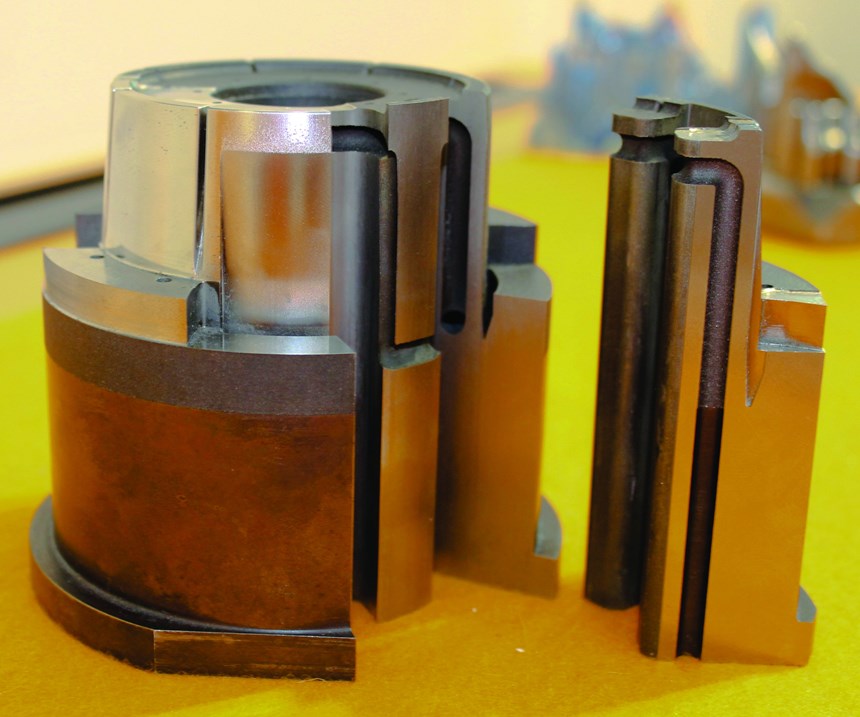

“There are several methods of creating conformal cooling systems in molds, including laser sintering and vacuum brazing,” Boretius says. “We have specialized in vacuum

brazing technology to fuse multi-component mold cores and cavity assemblies for conformal cooling systems, because it is a fully developed technology that can join different materials. For example, it can join copper and steel or steel and ceramics.”

Boretius admits that Listemann used to think of additive manufacturing technologies, like laser sintering, as rival technologies. Recently, however, the company realized that overlaps are small. “While vacuum brazing is ideal for large mold inserts and cores, multi-cavity applications and joining materials, laser sintering is more suitable for small cores and inserts, highly customized products and complex geometries. Both technologies can only realize about 5 percent of applications. A clear division exists.”

As a result, the company teamed up with Renishaw Inc., which took over Listemann’s partner for laser sintering applications (LBC Engineering) in 2013 and established a new brand named IQTemp (intelligence and quality for molds and dies). IQTemp formed to offer conformal cooling solutions to its customers using vacuum brazing and laser sintering.

“It’s about finding the most efficient and cost-effective conformal cooling design for our customers,” Renishaw’s Design Manager Carlo Hüsken says. “For example, if the cooling channels are too complex for milling and vacuum brazing, we will suggest laser-sintering them. Since the selective laser melting (SLM) process is expensive, we also might suggest producing parts of the core or insert conventionally and only manufacturing the part with the conformal cooling channels additively.”

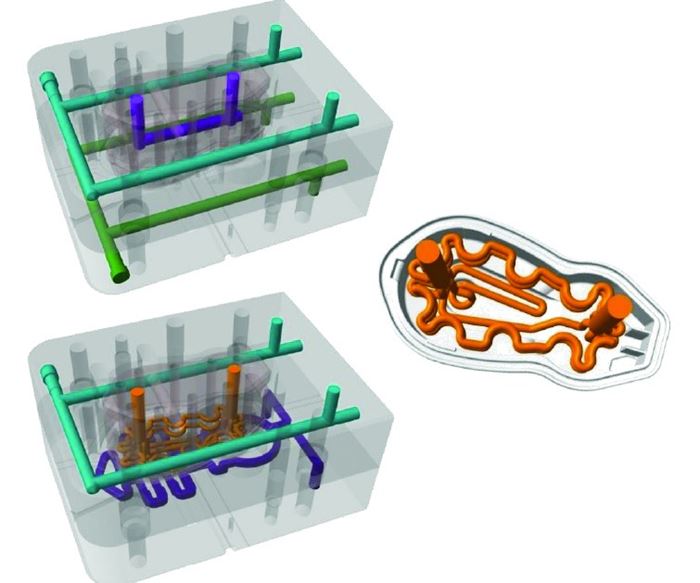

According to Hüsken, they use computational fluid dynamics (CFD) and thermal heat transfer analysis to determine the optimal conformal cooling solution. “We design different types of cooling channels in an injection mold virtually and compare the performance in terms of cooling time, temperature profile and part warpage. The injection molding condition during operation, for instance, dictates a minimum distance from the mold surface to the cooling channel. Considerations of pressure and drops in temperature along the flow channel are constraints for a successful design.”

Complex cooling channels can only be created using SLM. If the simulation shows that complex cooling channels offer the most potential for substantial improvement in production rate and part quality, the IQTemp team will suggest this design. The team will make that suggestion even if it is more expensive than using less complex channels, which are created from milling and vacuum brazing. However, if the simulation shows that both designs will produce the same results, they will suggest the less expensive solution of using less complex cooling channels.

While Hüsken and Boretius admit that they cannot yet create hybrid parts that feature laser-sintered and vacuum-brazed areas on a single part because of material constraints, the companies are currently conducting research. In some cases, conformal cooling channels for one mold are created using both technologies—one for the core and the other for the insert.

For example, IQTemp designed and manufactured an injection mold that had cycle times of 32.8 seconds with a cooling time of 18 seconds without conformal cooling. Cooling channels with an enhanced-flow design to create a highly turbulent flow inside the cooling channels could make the mold more efficient. Specifically, CFD analysis showed that this type of conformal cooling channel could reduce the cooling phase to 9.5 seconds, a time savings of about 47 percent. The mold insert was vacuum-brazed, while the mold core was laser-sintered.

IQTemp’s analysis showed that the creation of less complex, less expensive cooling channels using milling and vacuum brazing were sufficient for the mold insert to achieve the required reduction in cooling. However, the mold core needed complex channels to achieve the desired result, and laser sintering was the only option.

About the Author

Barbara Schulz

Barbara Schulz is Gardner Business Media’s European correspondent. She can be reached at bschulz@gardnerweb.com.

Related Content

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)