Build

3D Robotic Deposition Advances Conformal Cooling

A new conformal cooling technique has emerged, rooted in a multilayer robotic deposition technology that is capable of manufacturing near-net shape objects.

Read MoreAutomation and AM Help W. Fassnacht Werkzeug- und Formenbau Win Germany’s 2017 Toolmaker of the Year Title

Germany’s Toolmaker of the Year 2017 does things small but in a smart way when it comes to the design and manufacture of multi-component molds, in-mold-labeling and tools with integrated assembly functions.

Read MoreCNC Gives Moldmaker Greater Reach for Large, Contoured Molds

When building molds ranging in size from 150–5,000 tons, it is important to have CNC equipment that provides both the capacity and the capabilities to achieve accurate, efficient machining on a wide variety of jobs.

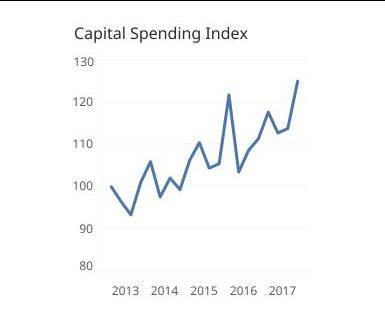

Read MoreGardner Industry Report: Automotive

New technologies coming to market in the next few years will require investments that will create sustained demand and industry growth for advanced automation, machinery, tooling, composites and plastics.

Read MoreTechnology Tuesday: Automation Fuels Productivity

Cruise through this week’s Technology Tuesday blog to see ways in which automation is boosting productivity and efficiency in moldmaking.

Read MoreOrderfox.com Launches US Site

Orderfox.com now provides a localized website to increase ease-of-use for U.S. moldmakers looking to advertise or hire CNC manufacturing services.

Read MoreHusky Strengthens Its PET Tooling Business

Husky is bringing its patented HyPET HPP5 technology to legacy systems and tooling generations to add value and capability for customers.

Read More3D Printer Makes Castable Wax Patterns for Creation of Master Molds

Solidcape says that the S500 3D Printer Package enables shops to create accurate, complex, precise wax patterns that can be directly cast in most metals and alloys.

Read MoreCollaborative Hot Runner Design to Improve Mold Performance

Improving injection mold performance requires understanding hot runner needs and options.

Read MoreTaking the Guesswork out of Cutting Tool Selection

Choosing effective cutting tools and operating parameters upfront often makes the difference between profit and loss on a milling job.

Watch