Taking the Guesswork out of Cutting Tool Selection

Choosing effective cutting tools and operating parameters upfront often makes the difference between profit and loss on a milling job.

Strategies vary for staying focused on increasing profitability and for remaining competitive in today’s global economy. Machining is an essential process for the strategy of mold builders.

This includes a focus on selecting and using the right cutting tools for each application. The first step to properly setting up each job that hits the shop floor is asking the right questions to assess requirements.

For example, how will you process the roughing and finishing on the part, what type of machine tool and cutting tools will you use for each process, what type of cutter geometry should you use when roughing and finishing, and what type of cutter material should you use, depending on its hardness and the age and capabilities of the machine tool?

These guidelines help answer questions and take some of the guesswork out of cutting tool selection and usage for cutting tool types and carbide grades for typical 3D mold applications.

Tool Type Selection

When selecting the appropriate tool for any roughing applications, consider these key factors.

On old, large, robust machines that are more than 10 years old, standard 90-degree, square shoulder cutting tools (see Figure 1) often achieve the best metal removal rate (MRR). These cutting tools can handle a heavy depth of cut (DOC) and do not require the high feed rates of some newer cutting tools. Tougher grades of carbide are required, as they provide good resistance to the shock and lack of rigidity that is common in older machines.

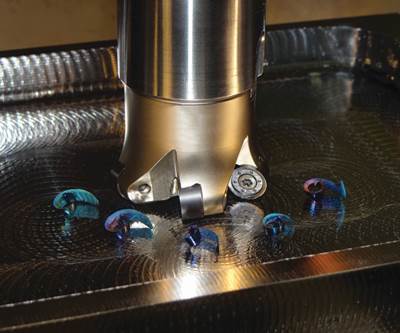

New, large, robust machines that are fewer than 10 years old typically achieve optimum MRR with high-feed or button milling tools (see Figure 2 and Figure 3, respectively) that are designed to run at higher feed rates with lower DOC than 90-degree cutting tools. High-feed and button milling tools require a machine and control that can quickly process programming information, as well as axis motors capable of smoothly executing rapid changes in direction. A button cutter supports a heavier DOC range, while a high-feed system uses fast feed rates better. A large, powerful, rigid machine is better off with a high-feed cutting tool system, as it can handle heavier DOC than a smaller cutting tool solution. Tools with mid-hardness grades of carbide work well here, as the newer machine’s rigidity often provides more uniform tool pressure, which makes it possible to run a longer-lasting, harder grade of carbide for more extended periods of time before indexing is required.

Old, small, light-duty machines that are more than 10 years old lack rigidity and processing speed. For these machines, button cutters with small diameters of 2 inches or less are often the optimal choice. Button cutters are capable of higher feed rates, but they do not require higher feed rates to succeed. Choose a DOC that the machine handles well and as much feed rate as the machine and control can accept without losing accuracy or repeatability. Tough-grade carbide inserts may help overcome any lingering rigidity issues.

New, small, light-duty machines that are fewer than 10 years old are common in mold and die work. The most affordable are 40-taper machines, and while generally not well suited to heavy cuts, modern machines are capable of feed rates that go well into the range of hundreds of inches per minute. Therefore, high-feed cutting tools are the best choice most of the time, as they operate at a light DOC and feed rates of 200–300 ipm. This helps increase metal removal rates and lengthen tool life. A controlled, rigid cut on a newer machine should support a mid-hardness, high-performance grade of carbide and yield greater tool life (or number of minutes in the cut) before indexing.

When it comes to semi-finishing and finishing applications, tool requirements vary. Both semi-finishing and finishing work involve lighter cuts, faster movement, higher accuracy requirements and smaller-diameter cutting tools. The use of finishing cutting tools for semi-finishing operations is an unconventional cutting strategy. However, the tool life and accuracy that finishing cutting tools offer during semi-finishing operations extends the time in the cut and provides greater accuracy and consistency in the finish stock that remains, which enables final finishing tools to do their work more easily.

For finishing work, sharp-edged cutting tools provide better surface finish and more accurate sizing. Finishing-style indexable cutting tools (which are precision-ground and sharp) and solid-carbide end mills are both suitable for finishing work. Indexable-style roughing tools are designed with heavier edge preparations, which makes them less suitable for a finishing cut where material removal is inadequate for a reinforced cutting edge.

Accuracy is also an issue with typical roughing inserts that have a larger inscribed circle (IC) tolerance (which defines the insert size) in comparison to a precision-finishing insert. Roughing inserts are typically pressed-to-size with a tolerance of ± 0.002 inch on the IC while precision-ground finishing tools carry a tighter tolerance of ± 0.0005 inch.

Ball nose cutters (see Figure 4) provide high-quality surface finishes for most 3D surfacing work by minimizing the scalloping (or waviness) effect. When conditions exist that jeopardize cutting-edge integrity, like long reach, machine ways/spindle play, vibration or chatter, the design of a ball nose insert and cutter helps tolerate more abuse before chipping occurs. The round cutting edge of a ball nose insert provides inherent strength because there are no sharp corners. This is also why button cutters (or round insert cutters) function well as roughing tools, as they have no corners to chip or break.

Bull nose cutting tools can also be used for 3D surfacing work, but the cutter may “heel,” or hit on the opposite side of the primary cutting point, when it encounters sharp bottom radii.

Backdraft-style cutting tools (see Figure 5) provide fine finishes and decrease tool pressure for both straight and tapered wall work. Water-line (or Z-level) finishing with these tools is the most common approach. It minimizes the depth engagement per pass to create the most accurate surface.

Plunge finishing is another approach that uses backdraft-style cutting tools in which the tool executes the primary finishing travel on the Z-axis and then moves to the X- or Y-axis for each stepover. This path yields a smaller scallop height and allows for larger stepover. This strategy works best when the surfaces being finished do not require the cutting to intersect with the surface’s floor.

Carbide Grade Selection

Carbide is the most common material for cutting tools, as it provides a good combination of toughness and hardness. Following are some additional factors to consider when choosing the appropriate grade for your application.

Generally, carbide does not respond well to the shock that results from roughing. The safest approach is to start with a grade that is tough and soft. Most major cutting tool manufacturers refer to the grade description by including a large number like 35 or 40 in the designation for their roughing inserts as opposed to a low number like 10 or 15 in the grade description for finishing work.

When using a tough grade, be aware of failure mechanisms, or reasons that the cutting tool must be indexed or changed. For example, be aware of flank wear (or the appearance of rubbing marks along the clearance angle of the cutting edge). This wear is consistent and preferable to chipping or fracturing, which can result in tool breakage, a scrapped part or even spindle damage.

If starting with a tough grade yields unacceptable tool life, try the next-hardest grade available. Today, a tougher carbide grade with a high-temperature coating provides acceptable MRR and tool life performance with more reliable wear predictability.

In most finishing cases, the harder the cutting tool material, or carbide grade, the better. Harder carbide grades (ISO K10-15) tend to hold their edge longer, which reduces the need for zero cuts because of the deflection from a worn cutting edge.

The trade-off from using a hard carbide grade is reduced shock resistance. While a hard grade does maintain edge shape longer, it is more prone to chipping or fracturing in a high-shock environment (where, for example, there are interruptions, vibration and chatter). Keeping cuts light with harder grades helps to maximize tool life.

Another benefit of harder finishing grades is heat resistance, which allows for faster speeds or machining of harder materials. Use hard grades combined with a high-temperature coating for finish machining of heat-treated steels, or steels with a Rockwell hardness of greater than 48. Many cutting tool manufacturers’ grade descriptions include temperature and heat resistance capabilities. Choosing the high-temperature end of the spectrum is required for many finishing applications, as it enables the cutting edge to maintain integrity longer before breakdown occurs.

Successful milling involves more than just the creation of good toolpath. It involves good decision-making in the tool selection process before programming begins. Correctly matching the cutting tool to the machine tool and using the right tool geometry for the application can provide optimal speed, accuracy and profitability.

About the Contributor

Mike Bitner

Mike Bitner is vice president of Dapra Corporation and directs its technical milling training program.

Related Content

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

Analyze This: Cutting Tool Performance

Examining a cutting tool’s performance values, not just its cost, reveals the true efficiency of machining processes.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More