CNC Gives Moldmaker Greater Reach for Large, Contoured Molds

When building molds ranging in size from 150–5,000 tons, it is important to have CNC equipment that provides both the capacity and the capabilities to achieve accurate, efficient machining on a wide variety of jobs.

When building molds ranging in size from 150–5,000 tons, it is important to have CNC equipment that provides both the capacity and the capabilities to achieve accurate, efficient machining on a wide variety of jobs. It also helps to be able to confidently run jobs unattended and reduce, if not eliminate, the need for secondary processes. Model Die and Mold Inc. has 67 employees and builds molds fitting that size range for customers who are original equipment manufacturers primarily in the automotive, heavy truck, luxury vehicles and public transportation industries. Monica Neibarger, project manager, says that the Wyoming, Michigan-based company manufactures between 150–300 molds a year, depending on size.

For a while, size was a challenging factor. “We were experiencing bottlenecks in our CNC finishing department, particularly with very large molds that had deep, contoured cavities. We had to outsource that work, causing a loss in profits,” she says. In addition, Model Die had to turn new work away because of insufficient CNC capacity and required delivery times.

To remedy the situation, the company began looking for a machine with a larger work envelope and, more importantly, the ability to cut deep, contoured cavities. Model Die already had two Parpas Diamond machining centers from Parpas America Corp. in Bloomfield Hills, Michigan. One is an Active Five five-axis gantry high-speed CNC mill, and the other is a Diamond Linear featuring an overhead gantry and five-axis head. Each has XYZ travels of 87 inches by 59 inches by 39 inches, and Neibarger says that they have been top performers in terms of speed (20,000 rpm), surface finish, five-axis precision and automatic tool changing capability (84-position and 40-position, respectively). “Investing in a new, larger Parpas Diamond 30 Linear machining center made sense, given the excellent performance of the machines we had,” she says, adding that the five-axis, gantry-style Diamond 30 provided the same benefits and more.

Increased Capacity Wins Work

Turning away work because of inadequate CNC capacity was frustrating for Model Die. Despite having another CNC Bridge Mill, which features a 44-inch Z travel, its table size maxed out at 72 inches by 136 inches. While the table size was generous, it was not enough to handle the very large and complex molds that Model Die was asked to quote.

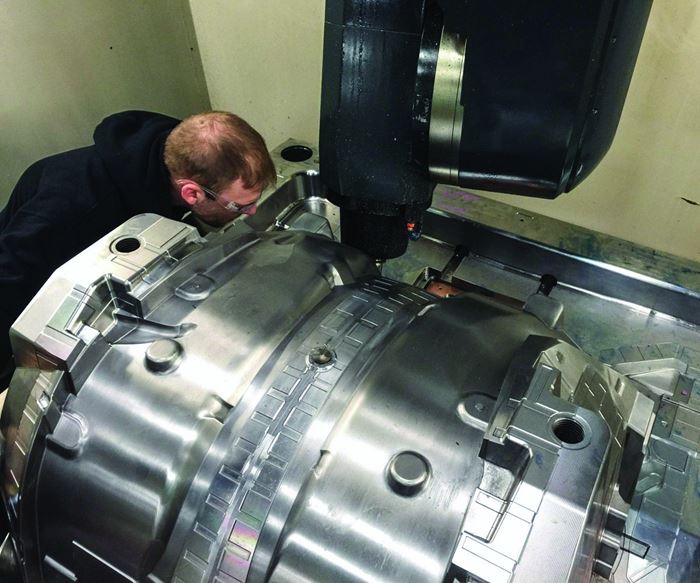

“The Parpas 30 has a Z travel of 47.25 inches and a table size of 118 inches by 102 inches,” Neibarger says. “The other CNC mill serves us well, but having that extra few inches on the Z travel can make a difference in whether we are able to set up and machine a large, detailed workpiece.” For example, she says the company recently used the Diamond 30 to machine what she believes is its largest mold-half to date, measuring 85 inches by 110 inches by 27 inches thick. Thomas Hagey, operations manager and sales professional at Parpas America, explains that the Diamond 30’s ability to machine large molds with very deep cavities can be attributed to its orthogonally-designed Model TOE-29 head. “The head’s A-axis indexes every 0.001º, and both the A and C axes can be used as machining axes,” he says. “Additionally, the TOE-29 has been designed to drastically reduce the length of tools when machining in deep cavities. In other words, the end of the TOE-29’s head has been designed with a longer snout compared to the same feature from many other manufacturers, thereby allowing for the use of much shorter tools.”

“Getting this machine enabled us to land new business that we would not have had otherwise because of the timing the customers needed it in, and our lack of capacity to take such large molds,” Monica Neibarger says. “We basically doubled our capacity for tools that are 24 inches and thicker with a lot of contouring, and we have greatly reduced the need to outsource work to other shops.”

Greater Reach, Stability Reduces EDM

Neibarger says that Model Die customers have been approaching them with an abundance of deep, contoured cavity work that required a lot of engraving along those contours. For this type of work, it was challenging to find an EDM machine large enough to allow use of the special setups required for reaching the deep areas of the cavities. For example, after machining, tight areas (and especially angled surfaces) would be left steel-safe, and then the company would have to build special beams from which the electrodes could hang while they burned engravings and other details onto the workpieces. The process was very time-intensive and expensive. “Our EDM tanks are large enough, but it requires special, multiple setups to get into those tight areas,” she says. It gave the company one more reason to invest in the Diamond 30. “It has a linear drive for better stability, so we have no trouble meeting customers’ specified tolerances,” she says. “The workpiece is stationary on the platen, and the cutting tool hangs down from the gantry so that it can move in X, Y and Z directions. The small, five-axis machining head rotates and tilts to get into corners and other tight spaces that otherwise would require EDM work.”

Hagey says that the X, Y, and Z axes are all run on linear guide-ways using linear motors. “These motors offer notable acceleration, reliability and consistency while machining. The A and C axes utilize direct torque-driven motors for increased machining power and accuracy,” he says. “These axes, including the X, Y, Z, A and C, are all measured using Heidenhain optical scales, making it possible to achieve a resolution of 0.001 millimeters (X, Y, Z) and 0.001° (A, C), respectively.” The Diamond 30 also features a third guiderail, which, together with Parpas’s patented Thermostatic System, improves the stability of the machine’s ram, especially when it is fully extended. He adds that because the TOE-29 head makes it possible to use shorter tools, additional advantages come into play. Advantages include less vibration between the tool and the milling piece, better machined surface quality, higher machining feed rates and reduced wear overall on the tools that are used.

Neibarger attests to those benefits. She says, “Now we are able to machine all required details onto the workpieces using the Diamond 30, with almost no EDM required. We added Delcam’s FeatureCAM software, which gives us the ability to loop programs together and not worry about a collision, particularly when we run lights out.” She says that the company’s goal is to be able to accomplish CNC finish machining on the mold’s B side, and reduced polishing on the A side using lights out operation and reduced EDM. “With our larger molds, there might be 1,900 hours of machining required and only 16 weeks or fewer to build a job, so we have to be able to run 24/7 confidently. We still do some outsourcing, but not nearly as much,” she says.

Neibarger shared a recent project that illustrates several of the advantages that the Parpas Diamond 30 brings to Model Die’s operations. “We recently built two large, deep tools that were mirror images. The cavity size was 30 inches deep by 52 inches by 80 inches. We machined everything on the Diamond 30,” she says. “Five years ago, we built two nearly identical molds with the same cavity size on equipment that was more than 10 years old.” When Model Die compared the actual production data between the two projects, they discovered that:

- CNC machine hours decreased by five percent because of the Parpas’s ability to reach and machine ribs and tighter areas with its smaller head and shorter tools.

- EDM hours decreased by 70 percent.

- Lights-out CNC machine hours increased by 10 percent, largely because the Diamond 30 has an automatic tool changer, which spared someone from having to stop in to change out tools.

- Polishing decreased by 27 percent.

- The Diamond 30 achieves a finer finish.

“Our overall mold-building time has been reduced by two weeks because of the Diamond 30,” she says. “It’s really been a game changer.”

Related Content

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More