Gardner Industry Report: Automotive

New technologies coming to market in the next few years will require investments that will create sustained demand and industry growth for advanced automation, machinery, tooling, composites and plastics.

Gardner Intelligence diligently works to provide MoldMaking Technology’s readers with information that connects economic data to the current and expected business conditions of its readers. To accomplish this goal, Gardner Intelligence collects both economic and equities data from Wall Street firms. By monitoring and reporting data from both domains, Gardner Intelligence creates a more comprehensive view of what is and what will happen in the specific manufacturing spaces covered by Gardner Business Media.

In recent months, we have called attention to declining car and flattening truck sales, among other high-level metrics. Yet, this broad-brush picture misses critical dynamics of the industry, such as how the introduction and mass-placement of new technologies and new drivetrains are creating significant demand for equipment in the automotive industry.

For this reason, Gardner Intelligence recently examined the financial statements of 14 major automotive original equipment manufacturers (OEMs) to discern possible industry trends in capital expenditures, new property plant and equipment and working capital. Gardner Intelligence selected these 14 OEMs because of the richness of the quarterly data they provided during these years in their Security and Exchange filings and then indexed this data to build a representative model of the industry.

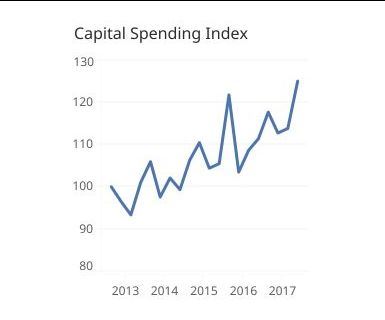

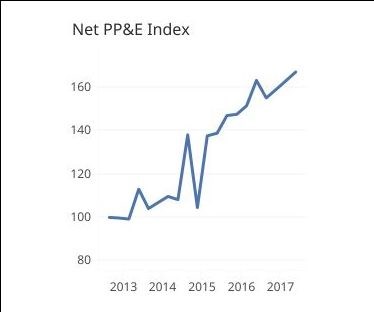

Gardner Intelligence found that between the fourth quarter of 2012 and the third quarter of 2017, Capital Expenditure grew at a nominal annualized rate of 4.7 percent. Unadjusted for inflation, the industry—as represented by our data—is spending 25 percent more on capital expenses than it did at the end of 2012. Additionally, Net Property Plant and Equipment data (Net PP&E) has grown even faster during this time with annualized growth of 17 percent. Net Property Plant and Equipment data includes a broader range of purchases including equipment and the depreciation of old equipment. The result is that Net Property Plant and Equipment today is nearly 70 percent higher than it was in 2012.

Working capital between 2012 and 2015 was relatively stable. In 2016, it fell by over 20 percent from its level at the end of 2012. At present, the 14 firms for which Gardner Intelligence has data are holding 73 percent of the working capital that they had at the end of 2012. Although working capital has diminished during these years, we see that major OEMs are spending more on R&D as a percentage of revenue than they did in the past. According to YCharts, for example, Honda and Daimler spent over 5 percent and 3.7 of their revenues, respectively, on R&D in the third quarter of 2017. This is significantly more than two years ago, when Honda spent 4.25 percent, and Daimler spent 3.25 percent of revenue on R&D in the third quarter of 2015.

While increasing sales in recent years has certainly bolstered some of these figures, it is important to realize that the new technologies coming to market in the next few years will require investments that will create sustained demand and industry growth for advanced automation, machinery, tooling, composites and plastics. All OEMs understand that the significant changes that their industries are facing and will continue to undergo in the next few years will result in significant purchases of more technically capable and complex equipment.

About the Author

Michael Guckes

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media, Inc. (Cincinnati, Ohio, United States). He has performed economic analysis, modeling and forecasting work for nearly 20 years among a range of industries. He is available at mguckes@gardnerweb.com.

Related Content

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreSteps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreRead Next

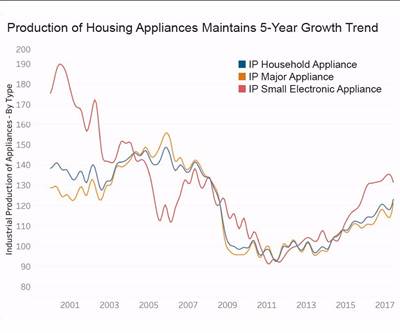

Gardner Industry Report: Appliance & Packaging

Industrial production data for household appliances through the second quarter of 2017 maintained the steady upward trend that started in early 2013. Since the beginning of 2016, packaging consumption has grown between 2 and 5 percent.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;width=70;height=70;mode=crop)