Build

CAMM, Automate Canada Release Coronavirus Impact Survey Results-Week 2

Employee anxiety was listed as the number one problem from Canadian Association of Mold Makers and Automate Canada survey respondents to a question on what is the biggest impact on their Canadian manufacturing business to date.

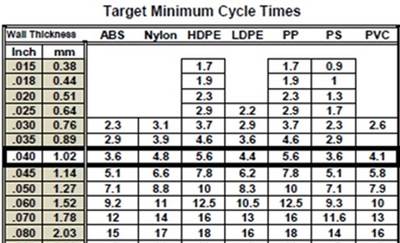

Read MoreHow to Make an Informed Hot Runner Decision

A proper hot runner assessment requires evaluating and calculating key runner system variables.

Read MoreORDERFOX.com Offers Free CNC Platform for CNC Industry During Coronavirus

Orderfox.com’s CNC platform is free of charge for the entire CNC industry with immediate effect until April 30, 2020.

Read MoreDirect Rapid Soft Molds Open Up New Applications in Micro Injection Molding

Nanofabrica's Direct Rapid Soft Tooling (DRST) process enables lead times of two hours from file to injected part. With up to 1000 injection-molded parts per tool, the technology unlocks potential applications in small or medium-batch manufacturing.

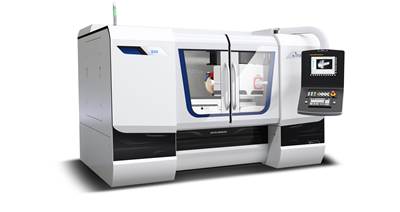

Read MoreInternal Cylindrical Grinders Designed for High Production

United Grinding offers a full 360-degree range of Studer internal cylindrical grinding machines.

Read MorePVD Coatings Solve Common 3D-Printed Mold and Part Problems

The right surface modification solution can alleviate a few common additive manufacturing pain points that typically require creating new molds or parts.

Read MoreInvestment in Advanced EDM Equipment Sets Shop Apart With Unique Wire EDM Capabilities

Extreme Wire EDM capitalizes on technology investment to carve out competitive advantages serving the moldmaking industry.

Read MoreCAMM, Automate Canada Release Coronavirus Impact Survey Results

The Canadian Association of Mold Makers (CAMM) and Automate Canada released the results of a recent COVID-19 impact survey.

Read MoreTooling Tech Group Completes TTG Automation Expansion

Tooling Tech Group has announced that its TTG Automation facility in Temperance, Michigan, has completed a 14,000 sq. ft. expansion.

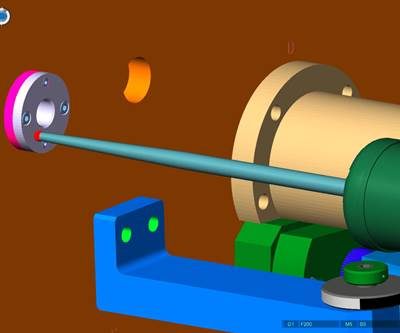

Read MoreSoftware Features Automation Functionality

The NCSIMUL machining module now includes automation functionality that provides wider control for jobs across various devices by communicating with distant servers.

Read More