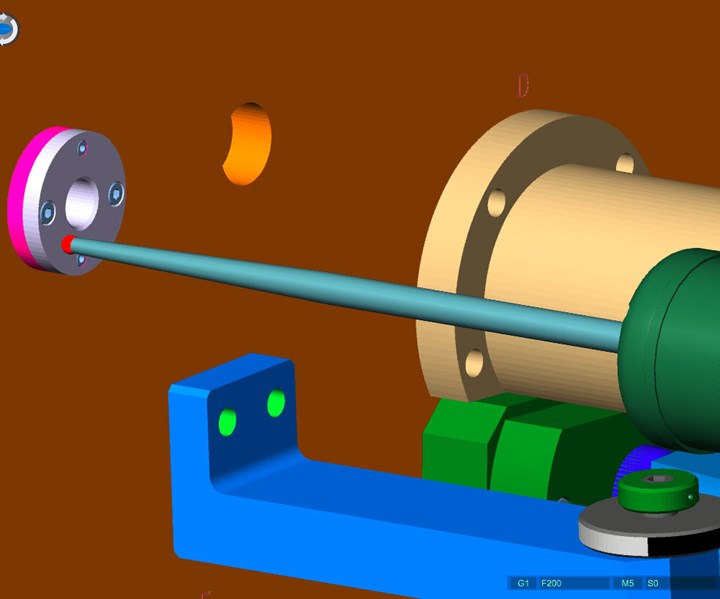

Software Features Automation Functionality

The NCSIMUL machining module now includes automation functionality that provides wider control for jobs across various devices by communicating with distant servers.

NCSIMUL from Hexagon Manufacturing Intelligence is designed to streamline CNC programming and increase shop-floor flexibility. Based on client-server scheduling architecture, the NCSIMUL machining module now includes automation functionality that provides wider control for jobs across various devices by communicating with distant servers. A dedicated graphical user interface now allows tasks such as simulation, cut analysis and 3D movies to be performed on any device. This enables users to follow the status of jobs and receive notifications when they are complete.

The NCSIMUL Automation Module provides a number of significant benefits, including a guarantee that 100 percent of the program sent to the shop floor is validated by simulation. The system enables users to implement their own automation rules according to constraints and production priorities, and tasks are featured in a command file that can be easily customized to include user-specified parameters. This delivers additional assurance that program verification and simulation accurately follow requirements.

Related Content

-

MMT Chats: The Rise of Tooling Digitalization

MoldMaking Technology Editorial Director Christina Fuges chats with Bob Vancoillie with the Consumer Division of Johnson & Johnson about OEM corporate initiatives for digitizing tooling.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

.jpg;maxWidth=300;quality=90)