Build

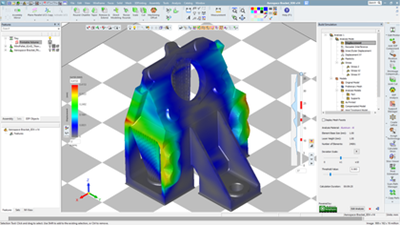

Software Add-On Streamlines Design for Additive Manufacturing Cycle

3D Systems launches its latest software solution 3DXpert for SolidWorks 15, which prepares and optimizes users’ designs for additive manufacturing.

Read MoreBar Locks Series Expand for Alignment of Large Molds

Progressive Components introduces an expansion of its Z-Series bar locks for alignment of large molds and multi-plate sequencing tools.

Read MoreCanadian Manufacturing Ramp Up Accelerating

After Canadian manufacturing began setting its return to work guidelines, ramp up is underway in manufacturing and automation, with health and safety and a mostly closed border being some key issues for manufacturers.

Read MoreRemote Validation Kit Expedites Qualifying Process

Progressive Components announces its remote validation kit, which enables tooling engineers to validate their tools remotely.

Read MoreMold Controllers with Virtual Network Computing Enables Remote Access

Husky Injection Molding System’s Altanium mold controllers are now available with virtual network computing (VNC) options.

Read MoreGuided Drill Addresses Large Component Challenges

Allied Machine & Engineering announces the guided T-A drill for moldmaking applications.

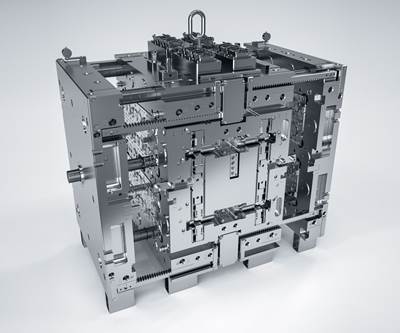

Read MoreTurnkey Mold and Tool Solutions Are Delivered Ready for Production

Roth Mold + Automation Inc. offers the manufacture of unique, high-precise and turnkey mold and tool solutions.

Read MoreThe Cool Parts Show Finds Additive Manufacturing Advancing During Pandemic Crisis

The Cool Parts Show, the series from Additive Manufacturing Media about 3D printing for industrial production, has produced special episodes about 3D printing during the COVID-19 crisis.

Read MoreDouble-Column Bridge Machine Increases Blow Moldmaker’s Capabilities

High-speed double-column bridge machining center runs faster and produces better surface finishes, increasing capabilities of blow mold builder M.C. Molds.

Read MoreFive-Axis Machining Requires Fewer Setups for Parts with Complex Geometry

Maximum Mold Group displays the benefits to having a large capacity five-axis CNC.

Read More