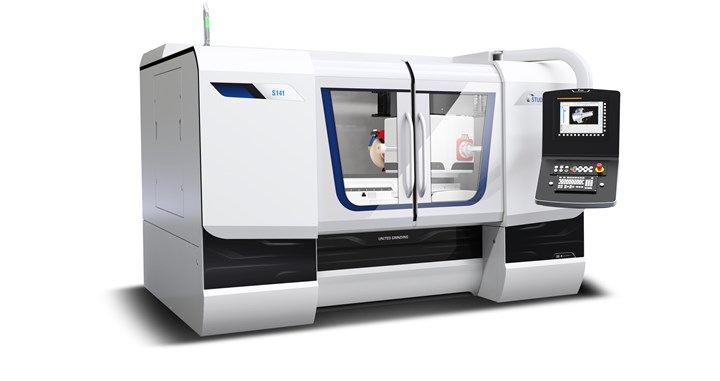

Internal Cylindrical Grinders Designed for High Production

United Grinding offers a full 360-degree range of Studer internal cylindrical grinding machines.

United Grinding offers a full 360-degree range of Studer internal cylindrical grinding machines. This machine portfolio includes several universal-type models as well as those designed for high production and for radii grinding operations.

The range includes models for workpieces up to 1300 mm long and weighing as much as 250 kg. Some models are well-suited for internal, surface and external grinding of chuck components, while others handle all other conceivable internal cylindrical grinding applications. The machines deliver the highest precision and efficiency, especially for flange parts, spindle shafts, spindle housings, rotor shafts, bushings and more.

Three models specialize in high-precision internal cylindrical grinding of radii, spheres, balls, cones and diameters. Applications include the manufacture of die plates from carbide and ceramic as well as the production of hydraulic components such as axial pump pistons, guide plates and housings from hardened steel, cast iron and copper. These machines are also well-suited for workpieces made from industrial ceramic, sapphire and carbide materials frequently used in the manufacture of human surgical implants.

StuderSIM software supports the automatic direct drive B-axes and enables the machines to interpolate for high-precision radii grinding. The operating system enables programming of all basic cycles for grinding, dressing and process-supporting measurement. This type of programming guarantees high flexibility together with maximum user-friendliness. After programming, the process can be simulated and optimized to ensure reliability, as well as shorten programming times and boost cost effectiveness.

For simplifying other complex internal cylindrical grinding operations, StuderWIN software enables the full integration of in-process gauging and sensor technology for process monitoring, including contact detection and automatic balancing systems within the operator interface for standardized programming across different systems.

Related Content

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.