PFA Inc.

N118 W8251 Bunsen Dr.

Germantown, WI 53022 US

262-250-4410

mscanlan@pfa-inc.com

pfa-inc.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

PFA Inc. Supplies the Following Products

- Air and Hydraulic Cylinders

- Mold Wiring

- Quick Mold Change Systems

- Side Actions or Cam Actions

- Switches or Indicators

Editorial, News, and Products

-

Preloading Slides for Optimal Mechanical Performance

Engineers use properly preloaded bolts, blocks, springs and side-action cores to enhance functionality and reliability in various mechanical systems.

-

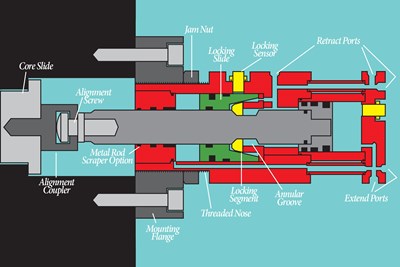

Hydraulic Locking Cylinders Offer Faster Mold Builds With Zero Flash Performance

Off-the-shelf Kor-Lok “mini” model 70 and other side action systems by PFA come in more stocking options and next-day delivery to accelerate mold production.

-

Products/Services for the Everyday Mold Builder

Happy New Year! MMT is bringing back its monthly technology/service roundups. Learn more about new and familiar companies, and the products available to the moldmaking industry.

-

Forces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

-

How to Solve Core Pull Flash and Part Issues

Many mold problems can be solved by simply providing enough preload force on the core to prevent movement.

-

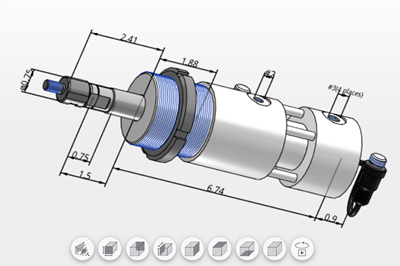

Hydraulic Core Puller Delivers Large Force in a Compact Size

PFA Inc.’s mini hydraulic locking cylinder delivers 8,000 pounds of preload force in a new narrow format, enabling multiple small cores to nest together and time independently.

-

Integrated Modular Cabling Standardizes Core Signal Wiring

With the PFA Switchmax, it is now possible to connect all core position sensors into single press inputs for set and pull and block unwanted signals.

-

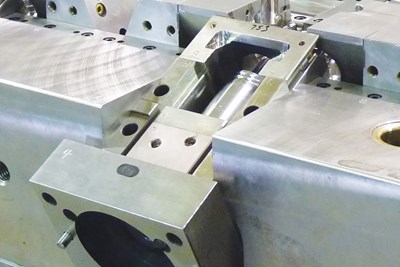

Side Action System Locks in Mold Performance

The PFA Kor-Lok side action system assists in high-quality part production in a smaller mold footprint with a high force preload and cylinder lock.

-

Hydraulic Mechanical Quick Mold Change for Aluminum Molds

The PFA Hydra-Jaws QMC system replaces common mechanical clamp systems and through bolt fastening methods with an easy-to-operate hydraulic mechanical clamping system.

-

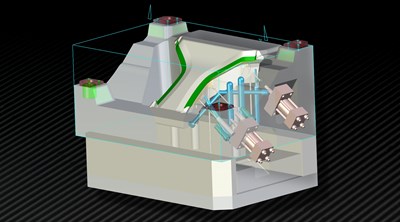

Parametric Hydraulic Locking Cylinder Models Cover All Native CAD Formats

PFA offers an enhanced user experience for all current and older versions of native CAD file formats, including Catia, Creo-ProE, Inventor and more.

-

Mini Hydraulic Locking Cylinder Provides Tremendous Preloading Capacity

PFA, Inc. announces the release of the 70 series “mini” hydraulic preloading and locking cylinder as part of the Kor-Lok side-action system product line.

-

How to Use Hydraulic Locking Cylinders to Improve Plastic Injection-Molded Part Profitability

Improve complex injection-molded part quality and profitability by reducing mold base size and preloading slides from a solid structure to ensure placement.

-

Hydraulic Locking Cylinder Provides Plug and Play Integration

PFA Inc.’s Hydraulic Locking Cylinders are now available with low profile PNP style sensors designed to integrate with Switchmax mold connectivity solution.

-

2018 Technology Review and Sourcing Guide: Mold Components

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold components.

-

Throwback Thursday: The Next Level of Mold Optimization

New technology gives everyone the ability to gain significant advantage, which pays off in faster builds, better performance, lower costs, and less-risk molds long into the future.

-

Throwback Thursday: Mold Side-Actions

Demands for improved quality, lower costs, shorter production times and increased part complexity persist, so this two-part series on thinking "outside of the box" when it comes to side-action methods is still very relevant.

-

In Search of the Infinite Processing Window

Side-action preload can yield zero core movement during injection and help molders achieve a robust molding process.

-

Modular Side-Action System in Medical Part Molding Reduces Downtime, Cycle Times

Case Study/Mold Components, Medical.

-

The Advantages of New Modular Tech: Maximizing ROI and Minimizing Risk

Proven off-the-shelf modular mold components and complete component systems meet today’s demanding drive for a lean approach.

-

Quick Math for Cylinder Calculations

Simple cylinder calculations provide good first look comparisons for proper sizing when moldmakers are considering the most suitable side-action option early in the mold design.

-

Mold Side-Actions: Applications Rule the Action

With a firm understanding of the effects of injection on the core, slide and associated components, this second of two articles will discuss emerging modular technologies which provide alternatives to the limited solutions previously available.

-

Mold Side-Actions: How, Why and When They Work

Understanding the effects of injection on the core, slide and associated components is critical to selecting the best side-action methods for a given application. This first of two articles will discuss the basic physics underlying all side-actions.