The Advantages of New Modular Tech: Maximizing ROI and Minimizing Risk

Proven off-the-shelf modular mold components and complete component systems meet today’s demanding drive for a lean approach.

You want to design, build, mold with, or own a great production mold, but you want to do so in a manner that makes the tooling easy and cost effective to make (designer, builder, owner) and simple and cost effective to maintain (molder, owner). Will highly customized and intricately timed out tooling give you the lowest total cost and lowest risk tooling you need? Answer: Probably not. But can you find a good balance between the custom part you are creating and off-the-shelf technology to get the best of both worlds? Answer: Yes, if you know what to look for and how to use it.

Custom tooling can be fraught with problems and risks that snowball out of control, turning a great project into a return on investment (ROI) nightmare. To reduce risk and lower costs, part design, mold design, mold materials, mold components, mold subsystems (side-actions, inserts, cylinders, ejector pins, etc.) and mold replacement parts (replacement cores, pins, wear plates, etc.) should be reviewed and optimized for lowest total design and build costs, lowest maintenance costs, and maximum uptime for the expected tool life. In many cases, off-the-shelf modular components, and more recently systems, are already optimized for low cost and low risk, due to mass production of a proven design. These systems often provide significant advantages beyond the mass production savings, to meet other specific challenges and dramatically improving ROI.

It All Starts with Design

Certainly the tradeoffs involved in mold design can be seemingly endless and the art of great mold design is the realm for the experienced; however, new technologies are emerging that provide significant simplifications and cost advantages, if they are considered early on in the design process.

Often new technologies are brought up as a last resort, retrofit, or quick fix making their implementation difficult. As human nature often dictates, we want the fix to fit neatly in our prior arrangements, so as to avoid the untidy issues of redesign. Designing around off-the-shelf components and systems as part of the planning stage; however, can make using new technology very straightforward—helping the designer and other affected parties realize the true benefits of design optimization.

Gaining an Understanding

Unfortunately, new technologies challenge our time and our understanding. Once understood, however, new technology gives everyone the ability to gain significant advantage, which pays off in faster builds, better performance, lower costs, and less risk molds long into the future. The new technologies usually also bring other advantages to others involved with the mold, as part of a total solution, whether they be the designer himself, builder, molder or mold owner.

The primary barrier to using new technology is therefore not primarily limited by a lack of desire to use it, but more often by our limited time or commitment to understand it. Due to curiosity if nothing else, most technology-directed people will take some amount of time to briefly determine How does it work?, when they see something new, but often do not take the time to consider all of the technology’s true advantages: How does it make other areas easier? More cost-effective? Lower costs? Basically, what makes it more lean than what I’m currently doing or planning to do? Or, why is this product for sale? What does the product provide as a design advantage? Build advantage? Process advantage? Maintenance advantage?

Armed with the understanding of a technology’s true advantages, the technology can be tried in appropriate applications and eventually the user adapts these to become another part of his art supplies for use on all appropriate future projects.

The term modular by its very nature implies such advantages and capability to optimize the design, mold build and maintenance processes, as does the term components. As typical screws and fasteners cover the range of common to specialized, so now does the world of mold components. In addition; however, mold components can be so much more.

The True Advantage Approach

Typical—and now even specialty—pins are available as “quickly available” or “off-the-shelf” items. More complex component systems are similar, although one must think of them as a single system component and not a custom product or complex arrangement.

Such system components demonstrate the next level of mold optimization. To illustrate and understand the true advantage approach to mold system components, we will consider the problem of moveable cores and mold wiring, and how the modular concept of more typical components also can be applied to systems (for a listing of these compared to typical components, see The Modular Concept).

Application

Considering an application where a side-action of some type may be required to form a complex part geometry, the tendency is to start designing the part with a core face planned at the easiest geometric location and adapting the remainder of the mold to make what will become an easier customer-designed cam action or cylinder block action easier to produce. In this process, the design from the onset begins to be constrained to require the incorporation of complexities of the mold gating, flow, other side-action needs—perhaps already building in a requirement for a large mold base.

Alternative

An alternative is to consider what other technologies might be used off the shelf to accomplish the side action task and what true advantages it has that could be applied to the specific design requirements. We will review one system, but this is only a single example of the greater concept and you are encouraged to consider all approaches in the known world to optimize your task.

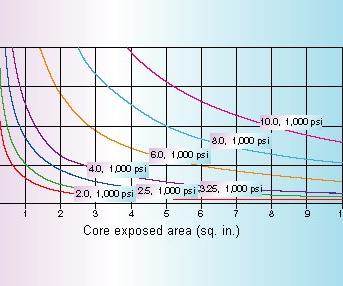

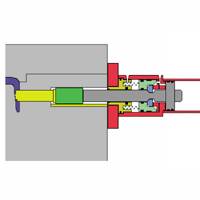

A preloading and locking cylinder style core system is one example. This system at the most basic level has a cylinder section to move the slide core to set and pull, and a mechanical high force locking and preloading force intensifier section to apply very large preload forces to the core in the set position and maintain the force at zero psi hydraulic.

Hydraulics move the cylinder forward and drive a wedge locking ring into a groove in the rod that creates a large output force at the end of stroke. The force is locked in by the shallow taper on the locking slide. To pull cores, hydraulics are applied to the pull port. The system operates with two ports just like a standard cylinder to the observer. Certainly a complex system relative to pins and counters, yet the interface to the mold as a system component consists of mounting the system flange to the mold base, connecting the rod end to the core and hooking up the standard hydraulic hoses of a normal cylinder—modular and simple.

Ask the Right Questions

While the how it works/what it does physically of the system described may be technically interesting or amazing even, what is needed is to ask some questions to discern the true advantage the manufacturer is trying to convey.

Why is this product important? Why is this product being sold? What particular advantage(s) does all that stuff about high force preload, zero psi hydraulics and force intensifier really imply? And most importantly, how does the product’s capabilities solve my problems, improve my design, and/or optimize the mold’s ROI as a total package for design, build, molding and maintenance?

Following are some true advantages:

Mold base can be made smaller.

- A great out of the box solution to getting molds into a smaller press is mounting a complete action outside the mold base itself.

- Lower material cost—cylinders stick out of the press area.

- Smaller press—lower per part costs in smaller press.

Complex angles become easier.

- Traditional actions are simplest when activating parallel and/or on the parting line; however, once the action is entirely modular, the mounting can be done at any complex geometry desired.

- Easier design—nesting of complex angled cores accomplished by cutting mounting flat and pocket only at desired angle—remaining action is bolted on.

- Less machining—simplified machine slots only—not action parts.

- Easier build—core timing no longer affected by opening of mold—timed separate.

Independent action operation.

- With complete autonomy and 100-percent force at zero psi, press issues with pressure dropout are eliminated and cores may be activated at any time as desired for best part quality.

- Pull or set cores any time in mold cycle—thin wall parts can be pulled before opening to maintain shape.

- Full core forces—high force output and locking in at zero psi provides consistency or quality.

The modular advantage, generally.

- Faster mold build—available off-the-shelf or very quickly.

- Faster repair—remove complete system and replace with spare.

- Lower risk—experienced and proven system, and easily integrated.

- Lower cost—pre-made with advantages of volume product passed along to customer.

Other advantages of the system.

- Improved quality—preload has side-action performance decoupled from injection force variations, temperature effects, pressure induced flex, compression and shutoff issues.

- Modular set sensing—integrated sensors connect to modular mold wiring solution to connect all sensors on the mold to the press with one plug without manual wiring—just plug them in.

- Modular repair—unbolt component system and replace with repaired or spare system. No drawings needed to repair system items as they are catalog items.

Take Your Time with Technology

As is often the case with complex component systems, the manufacturer is using either a combination of traditionally custom-made pieces or new and novel technologies to improve on the traditional combinations. In the above example, it is unlikely that many potential beneficiaries of the technology would have seen the benefits by a brief knowing of how it worked; however, with a little time spent thinking about it and asking why it exists, a few of the advantages might become rapidly apparent, while others really take some serious thought and more likely a call to the manufacturer or representative to explain the advantages in a particular application.

Alternatively, some manufacturers have significant information on their Web sites, so checking out Web sites is a great start, but don’t be afraid to call and get the scoop. Industrial manufacturers often fail to really describe the products, or may not use the terms or language you are used to. Some of the best technology often enters an industry from a very different one and the words or terms may not even exist to describe it. There also are me too products that might come out that do not have all the capability of the other systems or may be better or provide improvements that should be considered.

In other words, embrace new modular mold component technology in a way that brings the true advantages to light and you will be well on your way to improving ROI in all areas of the molding process. Whether you are a designer, builder, molder, owner or end user, you can help influence improvements through a better understanding of available technology and recommending these solutions at design meetings and during product reviews.

Enjoy the fun of the new modular mold technology available and you might find the process of improved lean manufacturing, improved ROI and reduced risk something that’s fun as well.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Mold Side-Actions: How, Why and When They Work

Understanding the effects of injection on the core, slide and associated components is critical to selecting the best side-action methods for a given application. This first of two articles will discuss the basic physics underlying all side-actions.

Read MoreMold Side-Actions: Applications Rule the Action

With a firm understanding of the effects of injection on the core, slide and associated components, this second of two articles will discuss emerging modular technologies which provide alternatives to the limited solutions previously available.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)