Side Action System Locks in Mold Performance

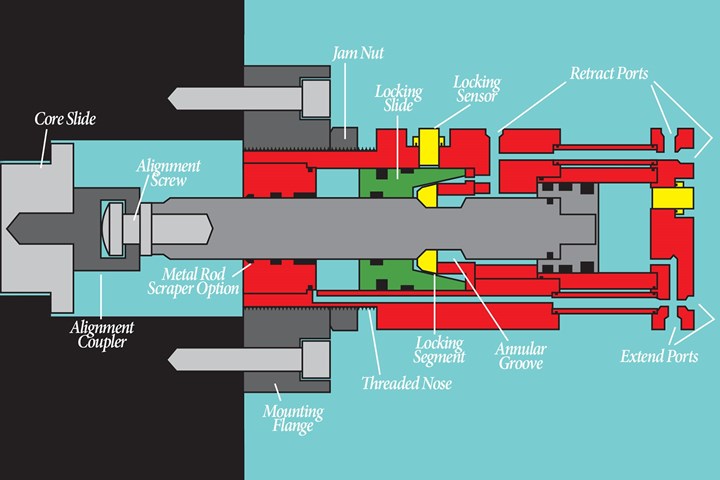

The PFA Kor-Lok side action system assists in high-quality part production in a smaller mold footprint with a high force preload and cylinder lock.

Photo Credit: PFA Inc

PFA Inc. provides a complete cylinder preloading and locking system for movable cores and core pulls on injection molds to help molders improve mold performance with off-the-shelf solutions, assisting in high-quality part production in a smaller mold footprint.

The PFA Kor-Lok side action system is said to have performance enhancements beyond standard hydraulic and locking cylinder systems with its ability to preload slides to high forces and maintain the force at 0 psi, a feature different from many traditional spring-locking, hydraulic-activated solutions which often do not lock, preload, or maintain force without hydraulics. While PFA makes other locking cylinders for general industrial use, only the Kor-Lok achieves high force preload and cylinder locking to fully rated load at 0 psi in a simple installation system.

Further, the hydra-mechanical wedge design multiplies applied hydraulic forces by as much as 10 times, allowing for high preload outputs in a small size when compared to standard hydraulic cylinders. The ability to mount the action external to the mold base also supports smaller mold base designs.

According to PFA, desired pressure and temperature changes to enhance part quality or improve molding will often cause the core face to “back up” or flex, changing the part geometry. Further, attempting to compensate for core compression and thermal effects with core timing and tweaking can often become time-intensive, repetitive, costly and unachievable. The ability to provide preloading above maximum injection force often eliminates movement errors.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.