ALBA Enterprises, Inc.

508 W 69th Street

Loveland, CO 80538 US

800-432-6653 | 909-941-0600

info@albaent.com

albaent.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

ALBA Enterprises, Inc. Supplies the Following Products

- Air and Hydraulic Cylinders

- Chillers

- Consulting Services

- Cooling Systems

- Fixtures

- Injection Molds

- Internal Mold Cooling Products

- Mold Bases and Frames

- Mold Insulation

- Mold Maintenance Training

- Mold Tryout Equipment

- Probes

- Quick Mold Change Systems

- Sampling/Mold Tryout Services

- Training and Consultancy Services—Additive Manufacturing

- Training and Workforce Development Services/Software

Editorial, News, and Products

-

Video: Mold Base for Product Development With 3D Printed Molds

Alba Enterprises created a mold base to match the needs and pacing of product iteration using mold tooling made via additive manufacturing.

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking enabled the speed necessary to iterate to a solution.

-

VIDEO: Using Data to Simplify Your Moldmaking Process

MMT editorial director, Christina Fuges, sits down with Injection Molding Solutions owner John Bozzelli and ALBA Enterprises president/CEO Rich Oles to discuss the importance of data in simplifying (emphasis on simple!) processes.

-

Alba Enterprises Relocated NA Headquarters, Opens New Facility

New production, service and training facility in Loveland, Colorado, ramps up 3D modeling and mold sampling capabilities in order to deliver comprehensive, multidisciplinary guidance solving application needs.

-

VIDEO: What Is Freeform Injection Molding?

FIM or freeform injection molding combines the proven injection molding process with the freedom of part design. Check out this video describing how this advanced technology works.

-

Getting Hot and Heavy during a Little Hot Runner Training

If a mold is the heart of a molding system, then the hot runner system is the heart of a hot runner mold, and I recently learned that there is a lot to know when it comes to designing and maintaining these systems to ensure optimal mold and part quality and performance.

-

Noteworthy News: Web-ducation

Improvement and success go hand in hand with continuous education on latest industry technologies and processes, so take a look at some upcoming and past webinars for you to educate yourself.

-

Simplicity and Consistency Are Key to Molds in Motion

A free webinar reviews solutions for the majority of mold (plastics) and die (die-casting) movements, including couplers, cylinders and latch assemblies, and listeners were engaged for the hour-long presentation to learn how simple concepts can have a big impact on the bottom line in both dollars and time.

-

MoldTrax Hot Runner Extravaganza Delivers on Expertise and Education

The “Who’s Who” in processing and hot runner technologies turned out to educate attendees with well-honed wisdom and experience.

-

Amerimold Action 2019

Amerimold celebrated 20 years in Rosemont, Illinois, and offered attendees a wide variety of products, programs and pomp.

-

Amerimold 2019: Attendees Will Benefit from Educational In-Booth Demos

Amerimold presents in-booth demonstrations of 3D printing, machining, hot runners, mold maintenance, molding, and more.

-

PODCAST: Let's Talk about Finding and Fixing Problems

With the goal of helping the customer, this dynamic duo sets out each day to find and fix problems. Their combined passion for and experience with hot runners and plastics processing is a perfect fit for taking their consulting services on the road regularly and applying them in their home facility in Torrance, California.

-

Amerimold 2019 Update: What You Should Know about Additive Manufacturing for Conformal Cooling

This panel discussion will present in detail the different AM technologies available today, their advantages and disadvantages, and specific ways to implement these technologies without issue.

-

VIDEO: How Does Thermal Imaging Communicate Thermal Dynamics in a Hot Runner System?

MoldMaking Technology Editorial Director Christina Fuges chats with Rich Oles president of Alba Enterprises about thermal imaging and how it communicates thermal dynamics in a hot runner system, how it picks up problems that other approaches cannot pick up at all or not as quickly, and how it will advance in the future.

-

Coupler Lends Easy, Reliable Solution to Quick Mold Change

A coupler helps provide a faster, more reliable way to tie positive return ejection into a mold.

-

Alba Enterprises Announces CEO

Rich Oles joins Alba Enterprises as President and CEO.

-

2018 Technology Review and Sourcing Guide: Mold Maintenance, Repair & Surface Treatment

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold maintenance, repair & surface treatment.

-

2018 Technology Review and Sourcing Guide: Inspection/Measurement

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including inspection/measurement.

-

2018 Technology Review and Sourcing Guide: Mold Components

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold components.

-

Three-Plate Latch System Installs and Adjusts Easily

The latch and cam plates separately attach to the mold to prevent over-stroking on the machine.

-

SLIDESHOW: Technology Tuesday, From 3D Printing to Mold Cleaning

MMT offers technical content in a variety of formats, including webinars. Here is a quick overview of some archived webinars that cover mold engineering, building and maintenance.

-

Rotating Devices for Continuous Threads

Molded plastic parts often are designed with continuous threads, and solutions for disengaging these parts from the mold vary. Unscrewing such parts from the mold cores requires a rotating device that is either a motor-driven or rack-and-pinion system.

-

Caring for Hydraulic Cylinders

Preventive maintenance on these important components will help keep a mold running.

-

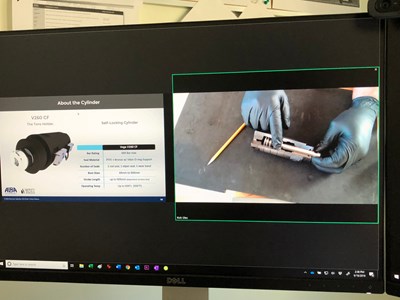

WEBINAR: How to PM Hydraulic Cylinders

MMT has covered how to simplify your mold designs with self-locking cylinders that enable movement of sliding cores without the need for heel blocks or additional cylinders, and on November 3rd we will present a free webinar on how to maintain those hydraulic cylinders.

-

Technology Showcase, Hot Runners and Mold Components

Take a look at this week's slideshow to see products that make building and/or maintaining molds more efficient and cost-effective.

-

Simplifying Mold Design

Self-locking cylinders enable movement of sliding cores without the need for heel blocks or additional cylinders. This allows for a smaller mold base, less complex mold design and reduced material costs.

-

Slideshow: Hot Runner Technology

Check out a few of the latest products in hot runner technology.

-

Common Sense Innovation and Moldmaker Collaboration

As I walked the aisles of NPE last month, taking in all the plastics-related technologies and solutions on display, two obvious trends emerged: logical innovation and moldmaker collaboration.

-

Simplify and Streamline

Technology suppliers discuss how equipment speeds time-to-market.

-

Micro Molding Machines

See Us at Booth #1170 and #1583

-

Hot Stuff!

Advances in valve gating technologies and improved efficiencies heat up the hot runner market in 2005.