Rotating Devices for Continuous Threads

Molded plastic parts often are designed with continuous threads, and solutions for disengaging these parts from the mold vary. Unscrewing such parts from the mold cores requires a rotating device that is either a motor-driven or rack-and-pinion system.

Molded plastic parts often are designed with continuous threads, and solutions for disengaging these parts from the mold vary. Unscrewing such parts from the mold cores requires a rotating device that is either a motor-driven or rack-and-pinion system.

Motor-driven systems employ either an electric or hydraulic motor and use a rotating shaft to actuate the core. This can be done directly with a single core or with the use of a gear train that rotates multiple cores together. Electric motors tend to spin quickly and have low torque, while hydraulic motors are slower and have higher torque values. Which type is more appropriate for the application depends on the mold requirements, however, generally speaking, electric motors can be efficiently used with small parts, while hydraulic motors are better for large parts.

Gears of different sizes can be added to control the speed and torque of electric motors, and to reach the desired results. Hydraulic motors can be controlled with a proportional valve. Belt and pulley systems often also are used, but belt materials (plastic) will limit the mold temperatures that can be achieved. Multi-cavity tools can be controlled by a train of gears or a sophisticated pulley system. Determining the proper motor and gear/pulley combination to ensure that the core returns to proper position for injection requires extensive engineering and motors with precise start and stop points.

In rack-and-pinion systems, the base motion is linear. This means that the rack (a long straight series of teeth) engages a gear or a train of gears that rotates the cores. This system generates large torque that depends on the type of gear train used. The force on the rack depends on the cylinder and ranges from 2,100 to 5,100 pounds per rack.

This category of rotating system also includes do-it-yourself (DIY) and compact systems that are supplied as drop-in ready. With a DIY system, the moldmaker assembles a standard hydraulic cylinder and a rack with guides. The benefit of this option is that all its parts are easily available on the market, and the stroke is defined by the hydraulic cylinder so sophisticated controls are not required. DIY systems are used in cases when size is not important and will only perform well if each part of the system is accurately machined and assembled.

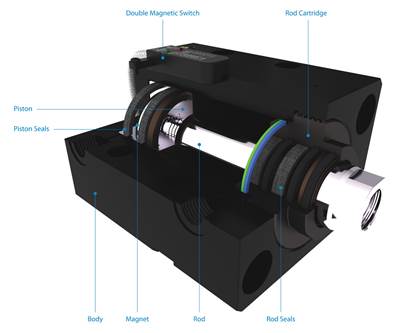

Compact systems are customized from a manufacturer’s standard part offerings (see photo) to meet the mold builder’s requirements, resulting in a unit that is ready to assemble in the mold. Typically, cylinder manufacturers use the most compact actuator they can to make the entire system more compact. For example, the rack is placed on its guide and fixed to the cylinder, reducing the length. For multi-core molds, a single rack can activate multiple pinions for multi-core control. In addition, double racks that use a single cylinder to control both racks can be installed to save space. Basically, the customer can use double the number of cores with just one cylinder. The added space is only for the second rack, plus its guide.

Switches for detecting rack end-positions are available to alert the machine when the cores are in the proper position for mold opening or closing. The price for a compact system is higher than a DIY system, but when component cost (including design and assembly time) is factored in, a compact system may be less expensive.

Related Content

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreRead Next

Caring for Hydraulic Cylinders

Preventive maintenance on these important components will help keep a mold running.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More