SLIDESHOW: Technology Tuesday, From 3D Printing to Mold Cleaning

MMT offers technical content in a variety of formats, including webinars. Here is a quick overview of some archived webinars that cover mold engineering, building and maintenance.

Webinars are an effective way to present information and a convenient way to consume that information. MMT offers on-demand webinars that cover topics including 3D printing, machine monitoring technology, tool shop optimization and CAM's impact on profitability.

Here are some of our more popular webinars.

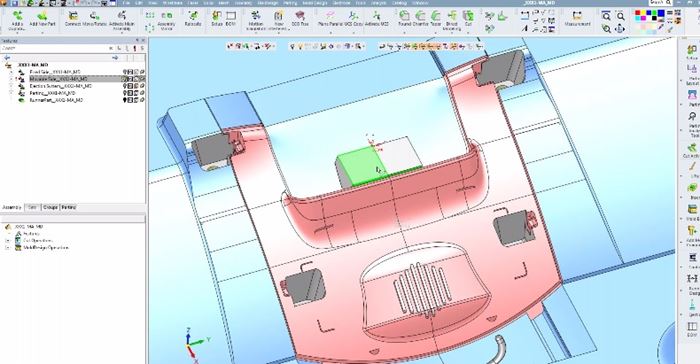

Mold designers – are you good at your job? Of course, you are! But, the question is – could you be better? The reality is you are only as good as the tools you have been given to do your job. Are the tools that YOU are using better than your competitors? This webinar shares how mold design tools and applications that you can use to help you excel in today’s competitive tooling market.

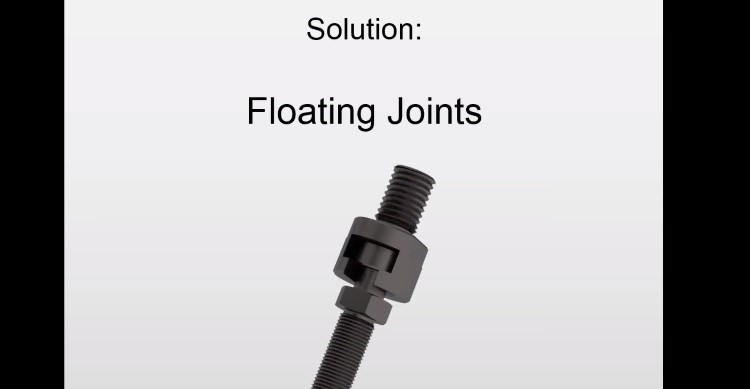

In order to maintain like-new performance of today’s high demand molds and hydraulic cylinders, proper preventative maintenance is important, as well as recognizing wear early, before a complete failure. Maintenance is, of course, easier when proper application is used. If unreasonable wear occurs, it is most likely due to misuse or improper maintenance. Check out this webinar.

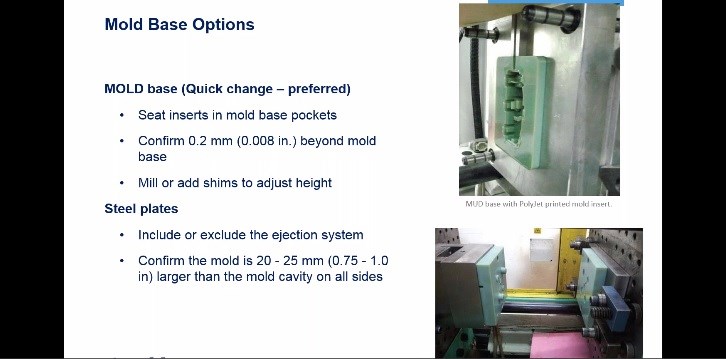

3D-printed inserts for mold prototypes can serve as a testing ground to quickly prove out production mold design options. This presentation takes a look at one project that put this theory to the test. An initial cost analysis and design review revealed that this plug type could not be economically produced by conventional injection molding. A collaborative prototyping method that combines 3D-printed cavities, cores and slide faces with a quick-change mold system and standard components was used and permitted rapid, low-cost prototypes that helped design and manufacture a better production mold.

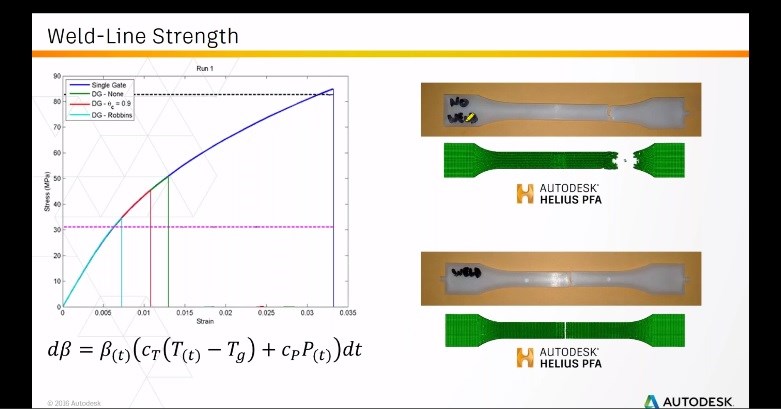

This webinar investigates the requirements for simulating the structural performance of assemblies of plastic components subjected to mechanical and thermal loading by looking at a real world component. We will include manufacturing induced properties from Autodesk Moldflow, such as fiber orientations and weld lines, to simulate the structural performance of a plastic assembly. We will investigate the anisotropy induced by spatially varying fiber orientation, material nonlinearity and rupture, and the effect of the manufacturing process on weld line strength.

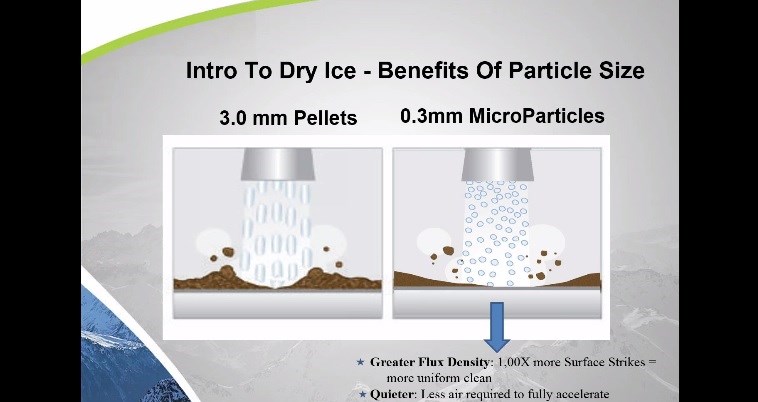

Tooling is the heart of the molding process and cleaning it can lead to mold wear. This presentation is an integrated approach to how recycled dry ice is used to clean mold cavities and vents in the press, faster, better and without causing mold wear. The five reasons mold cleaning should be celebrated instead of postponed will be discussed. Much of the information shared in this webinar comes from actual, current industry applications. Studies examining the use of dry ice to clean tooling from a mechanical, thermal and chemical viewpoint will also be discussed.

Visit our webinar page here.