Mold Components Target Route Cooling Lines

Progressive Components offers mold designers more route cooling line options within the tool with Diverting Rods, Seal Cores and O-Rings.

Photo Credit: Progressive Components

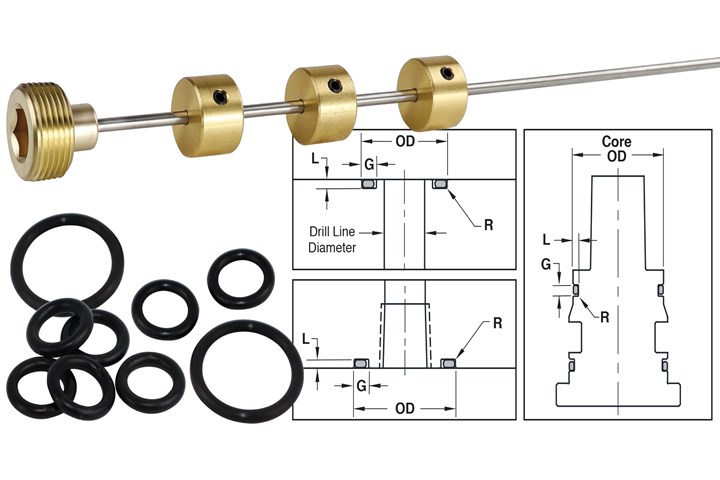

Progressive Components’ O-Rings addition provides mold designers with more route cooling line options within their tools, and an industry-standard that includes the machine groove detail. With this standardization, the subsequent replacement during mold maintenance has been made easier to locate and purchase by mold maintenance managers. O-Rings are available for both face sealing and core sealing applications and are offered in two material options: Buna-N for temperatures up to 225°F and Viton for temperatures up to 400°F. Sizes range from 0.566 OD to 4.872 OD, and cross-sections of 1/16th, 3/32nd and 1/8th.

New Diverting Rods and Plugs route water flow within cooling circuits. While the mold is on the bench, Plugs can be assembled along the locating rod, enabling positive installation and easy removal. The rod is designed to stay in the center of the cooling channel, allowing maximum heat transfer within the line.

Related Content

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

-

How to Use Simulation to Achieve a High-Gloss Surface Finish

Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts.

-

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.