Mold Builder Grows Mold Training, Additive Tooling Via Industry Partnerships

NPE2024: Westminster Tool is showcasing how it continues to expand its toolmaking knowledge through latest case studies, and mold qualification and injection molding training expansion.

Westminster Tool is highlighting new developments with industry partnerships, including expanding its mold qualification and injection molding training with new Sumitomo SHI Demag machines and new case studies with metal 3D printing partner Mantle. Westminster Tool says that its suppliers and partners are a critical component to serving its customers.

Adding the latest Sumitomo injection molding machines to its fleet, Westminster Tool plans to expand its mold qualification capabilities to support customers with services such as adjusting processing parameters, developing production-quality prototype parts and troubleshooting molding challenges. These include adding a Sumitomo SE100EV-A and Sumitomo SE130EV-A. With the machines’ new home at Westminster Tool, the company’s technology center will serve as a training center for regional Sumitomo customers as well as a training center for students studying plastics at the local community colleges.

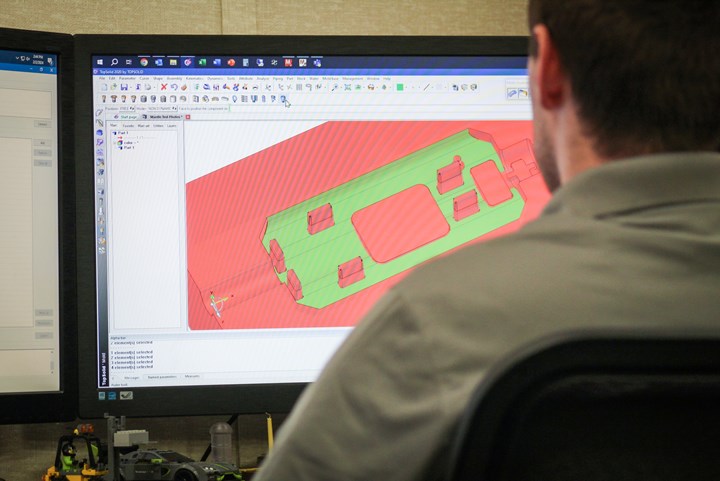

Westminster Tool is also speaking on stage at NPE 2024 about its latest case studies using metal 3D-printed tooling produced with Mantle’s technology. No stranger to using additive in toolmaking, Westminster Tool is presenting its findings at the Additive Workshop and the NPE Mold Building Track on May 8th.

Related Content

-

Plastic Injection Molder Debuts EOAT, Mold Monitoring Solutions

NPE2024: Exhibiting for the first time, European-based Mouldpro ApS highlights new solutions — the Roborex and Flosense — alongside partner Globeius.

-

Moldmaker Highlights Domestic Mold Expertise for Plastics Industry

MSI Mold Builders has the ability to develop a full range of injection molds and structural foam molds domestically, meeting the needs of U.S.-based molders.

-

Hydraulic Gating Cutting Reliably Separates Molded Parts

NPE2024: Material displacement technology offered by Ermanno Balzi Srl enables precise separation of the molded part from the gate during the molding cycle.