Plastic Injection Molder Debuts EOAT, Mold Monitoring Solutions

NPE2024: Exhibiting for the first time, European-based Mouldpro ApS highlights new solutions — the Roborex and Flosense — alongside partner Globeius.

Denmark-based Mouldpro ApS is exhibiting for the first time with Globeius Inc., partner and exclusive North American distributor for Mouldpro. The company is a well-established supplier of products for plastic injection molding, hoping to bring European quality to the U.S. at competitive pricing.

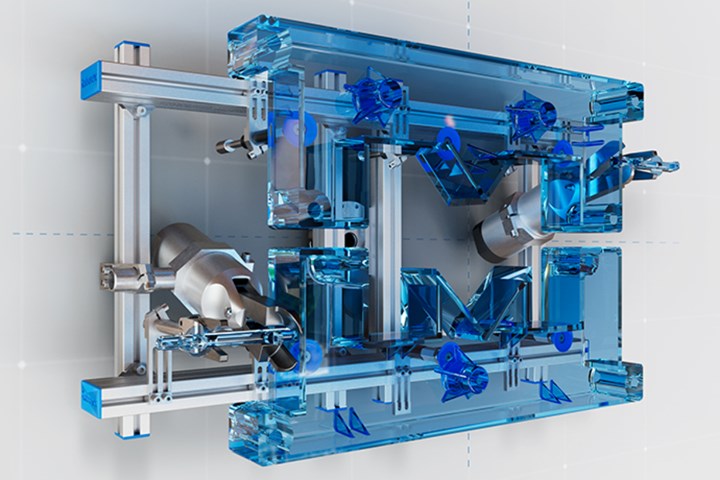

In addition to showing visitors a wide range of general products and supplies for injection molding, recently introduced Mouldpro products and two new offerings are available to attendees.

One innovation, Roborex, is making its debut at the show. The end-of-arm tooling (EOAT) helps streamline automation and increase productivity in the molding process.

Also making its debut is the Flosense thermal management/mold monitoring system. Flosense provides optimum control over mold cooling processes, reducing cycle times. It is both affordable and flexible, making it indispensable for those who desire to reduce costs while improving processing control and quality, according to Mouldpro. The system uses sensors to measure the differences in input and output temperatures (Delta T) and pressures (Delta P) as well as total flow rate through the system. It also alerts technicians in real time about the stability of the process and any potential issues, such as waterline blockages or leaks, heater or cooler malfunctions and so on. Many more features will be demonstrated at the booth.

Related Content

-

Dynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

Moldmaker Highlights Domestic Mold Expertise for Plastics Industry

MSI Mold Builders has the ability to develop a full range of injection molds and structural foam molds domestically, meeting the needs of U.S.-based molders.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)