INCOE Puts Direct Gated Valve Gate Component on Display at Amerimold 2021

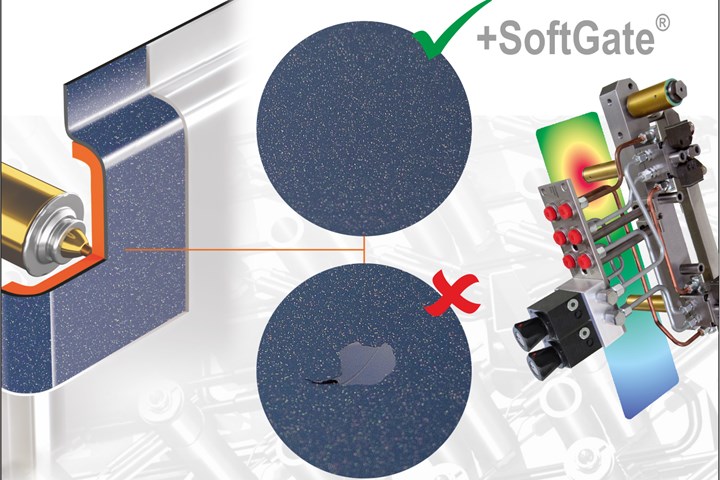

The SoftGate Velocity VG pin from INCOE allows for a “gentle” plastic flow to eliminate blemishes to the decorative film.

Photo Credit: INCOE

Several years ago, INCOE recognized the challenge of direct valve gating a part while overmolding film or fabric in mold decorating. For example, the “blast” of the plastic in the gate area can often damage the film or wrinkle the fabric. Using control technology, the company’s SoftGate Velocity VG pin enables these applications to be direct gated. This allows for the “gentle” flow of plastic into the cavity, eliminating blemishes that can occur with uncontrolled flow.

The impact caused by melt flowing abruptly into the cavity after a conventional valve gate nozzle has been opened can be seen in the image detail above: After SoftGate was switched off, the decorative film broke in the gate area.

INCOE will be exhibiting this hot runner technology at Amerimold 2021.

Exhibitor: INCOE Corporation

Booth 211 (P)

Related Content

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.