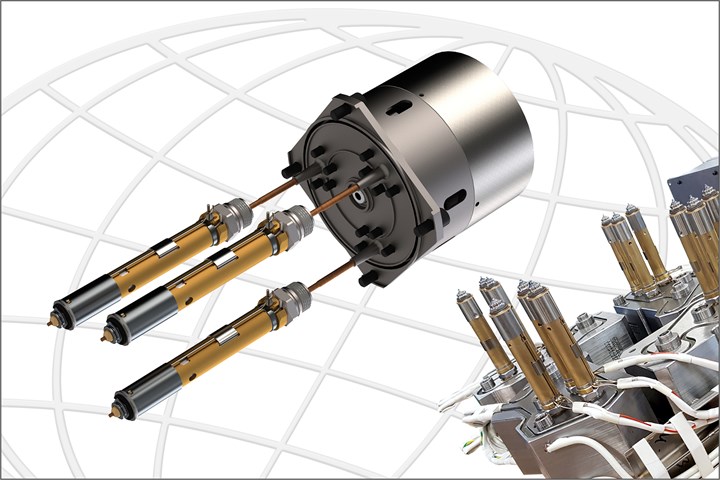

MultiPin Actuator Supports Multiple Valve Gate Nozzle Interconnections

The INCOE pneumatic MultiPin valve gate actuator has a user-friendly valve pin quick coupling and can accept up to four gate valves.

For valve gate applications in which multiple nozzles have to be positioned in the most confined space, and need to be opened and closed simultaneously, hot runner manufacturer INCOE has developed the new pneumatic MultiPin valve gate actuator in two sizes.

Based on its proven pneumatic (PE) units and designed for the (Slim) DF 5 and (Slim) DF 8 nozzle series, the MultiPin actuators are said to support the interconnection of up to four valve gate nozzles with cylindrical valve pin tip (ZTT). The product also features a quick coupling, which has been developed for easier maintenance and assembly. With a single set screw, all valve pins can reliably be locked or released simultaneously, to enable dismantling of the actuator housing, for example, without having to remove the valve pins from the nozzles.

In addition to simple and reliable handling for moldmakers and fitters, INCOE says the emphasis in developing MultiPin actuators was on integrating a standardized product that would allow the designer to implement multiple valve gate nozzles without having to resort to custom solutions involving special components. The standardized adapter plates for the MultiPin actuators can accept two, three or four gate valves. Depending on size, nozzle series and the number of attached valve gate nozzles, pitch/bolt circle dimensions between the nozzles with a minimum of 25 mm and a maximum of 63 mm can be implemented.

The MultiPin actuator is directly mounted on the manifold. With its novel design, the connecting elements between manifold and actuator require no additional cooling.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.