Products

Low-Heat Green Laser Targets Delicate Substrates for Direct Part Marking

Foba has developed a new 532-nm-wavelength green laser marking system that enables optical part inspection and validation of marked contents as well as the automated and precise positioning of the laser mark.

Read MoreSurface Damage Assessment Software Platform for Nondestructive Testing Service Providers

Creaform is launching a new, complete NDT software platform, VXintegrity, designed to tackle any surface analyses as well as simple metrology applications.

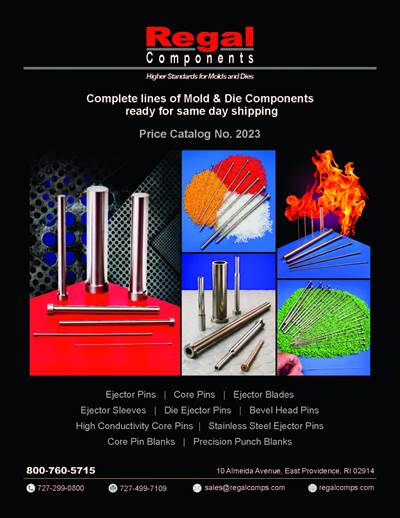

Read MoreMold and Die Catalog Simplifies Parts Ordering

The Regal Components Price Catalog No. 2023 offers complete information for the company’s mold and die component lines and easy template forms for custom-designed parts.

Read MoreRobust Software Functions Improve CNC Milling, Grinding Turning

Siemens Sinumerik 828D CNC with version 4.8 operating software offers significant increase in hardware and software options for mid-range control.

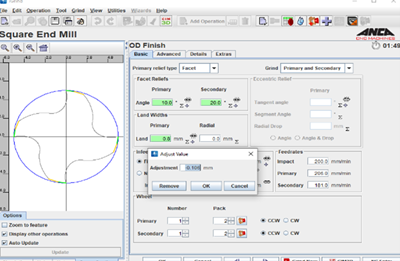

Read MoreCutting Tool Measurement, Compensation Expands to Meet Tool Needs

Zoller’s measurement machines and ANCA software easily communicate to simplify and improve tool measurement, wheel measurement, form measurement and compensation processes.

Read MoreNew App for Moldmakers Adds Functions, Part Scanner

Hasco’s new app has a number of new and augmented functions including an NFC (near-field communication) scan for reliable identification of original Hasco products.

Read MoreVMC Provides Shorter Cycle Times, Minimizes Non-Cutting Time

The SVM 5100L joins DN Solutions' vertical machining center lineup for die-cast components.

Read MoreNew Temperature Controller, Hot Runner for Micro Molders

Günther unveiled a new hot runner temperature controller and a specialized hot runner built specifically for the Babyplast line of molding machines at K 2022.

Read MoreHigh-Torque Air Grinder is Highly Effective for Deburring, Die Polishing

Added to Boride’s micro grinder series, the HTSG-3S is an ideal tool for polishing and precision grinding, with stable torque and constant grinding performance.

Read MoreMachine Tool Breakage Detector Enhances Mold Manufacturing Reliability

Heidenhain’s new TD 110 is a fast, contact-free, in-process gage that can quickly inspect drill bits and end mills, even while spinning at their operational speed.

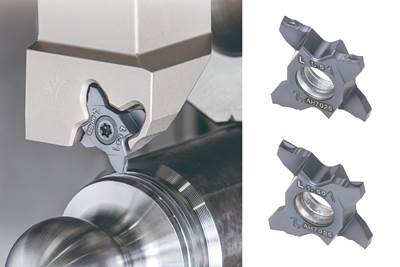

Read MoreLeft-Hand Cutting Tools Increase Multitasking Machine Productivity

With multitasking machines gaining popularity across manufacturers, including moldmakers, the expansion of Tungaloy’s TetraMiniCut’s ensures simultaneous machining on the left- and right-hand spindles of such machines.

Read MoreWashdown Tool Efficiently Washes Away Chips Between Machining Cycles

The in-between-processes device introduced by Jergens provides a 360º spray of coolant flow at scheduled intervals, shortening cleaning time and supporting long machining cycles.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)