Products

High-Speed, Five-Axis Mold Machining Achieved via Extended Barrel Series

Air Turbine Tool spindles can machine at 50,000 rpm in high-speed steel (HSS), accelerating mold machining capabilities.

Read MoreForm Grinder's Advanced Design is Ideal for Mold Base Prep, Inserts

The Okamoto full-function, two-axis, simultaneous CNC form grinder is ideal for surface, slot, step, form and contour grinding, with improved column design and construction, and consistent accuracy.

Read MoreRobot Guide Streamlines the Automation Process

The KUKA guide, accessible online, presents manufacturers robot options based on industry, application and environment for an optimal automation match.

Read MoreLarge Mold Shops can Boost Electrode Wear, Cycle Times with Workhorse Sinker EDM

The MC Machinery Gantry Eagle 1400 sinker EDM combines the latest in technological innovation with a human-centric design for utility across industries.

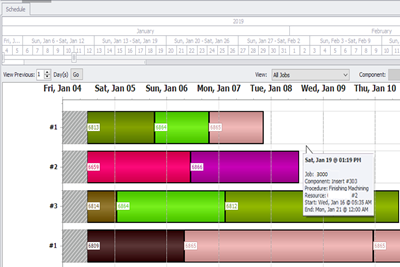

Read MoreManufacturing Execution System Automates Task Scheduling for Forward-Thinking Mold Shops

The R.E.R Software AutoPlan is a living schedule, capable of aligning hundreds of thousands of tasks with varying capabilities while reacting to the complexities of manufacturing facilities.

Read MoreHigh-Frequency Milling Suits Compact Gantry Milling Machine to Moldmaking Tasks

German-made Endura 700Linear series from Fooke is capable of various machining workpiece tasks, including composite, aluminum, cast iron and steel for mold and die-making.

Read MoreRotating Wire Function Cuts EDM Wire Consumption, Optimizes Mold Cutting Conditions

Sodick puts a new spin on its ALN and ALP wire EDM line with a new function that reduce wire consumption by 25% and improve the geometric accuracy and surface quality of workpieces.

Read MoreHybrid 3D Printer Offers Five-Axis Simultaneous Machining for Mold and Die Applications

DMG MORI’s Lasertec 3000 DED hybrid 3D printer offers process integration by combining laser deposition welding with five-axis, turn-mill machining in one setup.

Read MoreFree-Form, Mold and Die Machining Cycle Times Cut With Multitasking Machine

It is said the machine combines the abilities of a high-powered turning center with a full-function machining center to produce small- and medium-sized workpieces in single setups.

Read MoreCustom-Manufactured Core Pins, Punches, Blades and Sleeves

Regal Components offers its Special Mold & Die Components, precision ground to ±0.000050" tolerances and customizable in a range of tool steels, for manufacturers, distributors and end users.

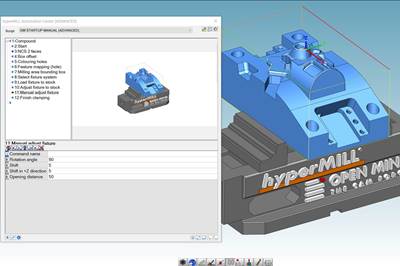

Read MoreCAM Software Automation Recognizes, Remembers and Standardizes Complex Process Flows

For the everyday mold builder, Open Mind Technologies’ hyperMILL software with automation technology and a comprehensive Automation Center make it easier to define and adhere to manufacturing standards.

Read MoreCylindrical Grinding System Extends Into Mold and Die Machining

United Grinding’s Studer brand unveils the S36 concept, featuring precise, reproducible cooling capabilities and a large grinding wheel for enhanced punch and die speeds.

Read More

.jpg;maxWidth=300;quality=90)