Products

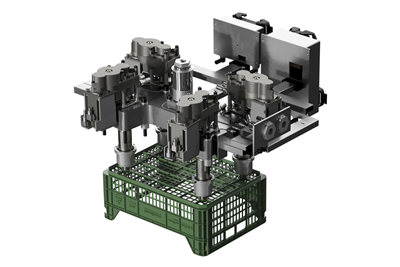

Optimized Hot Runner Systems for PCR Compounds

Hot runner systems manufacturer Oerlikon HRSflow is developing new hot runner solutions to help create new products including fruit crates and home composting buckets.

Read MoreNew Tool Breakage Alarm System Mitigates Machining Damage

If a cutting tool breaks or compressor malfunctions the Tool Breakage Alarm from Air Turbine Tools alerts operators, or stops the program altogether.

Read More“Graph Interpretation for Injection Molding” Course Available to Moldmakers

The new three-day RJG course offer classroom-style learning and hands-on applications for technical and non-technical personnel. The first course is to be held Dec. 13-15, 2022.

Read MoreNoncontact Tactile Measurement Tool Advances Moldmaking Equipment

The Laser Contour Check from Walter, a brand of United Grinding, combines a blue laser and intelligent measuring system to accurately measure tool parameters on grinding and eroding machines.

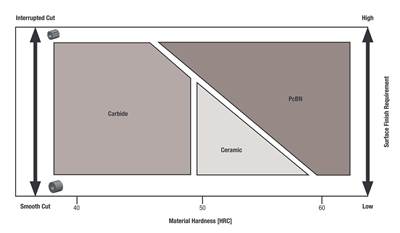

Read MoreCeramic Grade Increases Productivity When Machining Hardened Steels, High-Temp Alloys, Cast Irons

Higher wear resistance and longer tool life in hard turning applications up to 58 HRC with Kennametal’s KYHK15B grade.

Read MoreBoring Head Tool Extension Achieves More Precise Holemaking

Allied Machine expands the Wohlhaupter boring tool product line 420 (410) series and 465 (464), with smaller sizes now available.

Read MoreUpgraded Turning Center Series Drives Precise Machining, High Productivity

The new Puma DNT 2100 and 2600 from DN Solutions are offered in a two-axis and a milling version, with rigidity, usability and accuracy enhancements.

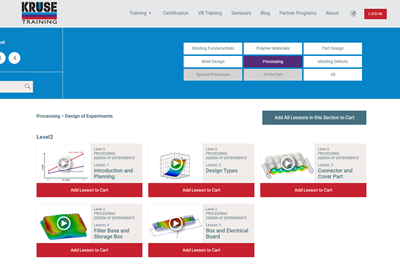

Read MoreFive New Design of Experiments Lessons Available

Kruse Analysis provides part designers, mold designers and senior process engineers with five new sessions on the subject of design of experiments (DOE).

Read MoreRound Inserts for Mold/Die Machines Boost Free-Forming Milling Reliability, Productivity

The new FixRMill insert introduced by Tungaloy retains anti-rotation notches to prevent insert rotation and achieve a true index each time.

Read MoreDie-Sinker EDM Series Fits Needs for Enhanced Automation, Speed, Surface Finish

The Sodick ALG EDM series doubles motor response speed for the development of accurate, high-quality molds, and is equipped with automated features for continuous operations.

Read MoreFive-Axis Volumetric Compensation Updates Eases Adoption Pain Points when Mold Machining

A new development, the GSC Advanced, offered with Grob’s five-axis universal systems for mold machining, ensures that compensation calibrations can be run even while the workpiece is in the machine.

Read MoreSinker EDM Complements Mold and Die, General Parts Machining Applications

YCM Alliance highlights the exeron 316’s ultra-high precision, large envelope and proven reliability.

Read More

.jpg;maxWidth=300;quality=90)