Products

Temperature Control Units Attain Precise, Easy Hot Runner Control

Developments and new innovations for highly productive, accurate and reliable hot runner temperature control units to be used in the injection molding process are presented by Hasco Hot Runner.

Read MoreInjection Mold Builder Meets Customer Challenges Via Complex, Precision State-of-the-Art Moldmaking

Accede, an independent and privately owned injection mold builder, understands that the job is not finished until its customers’ needs are met.

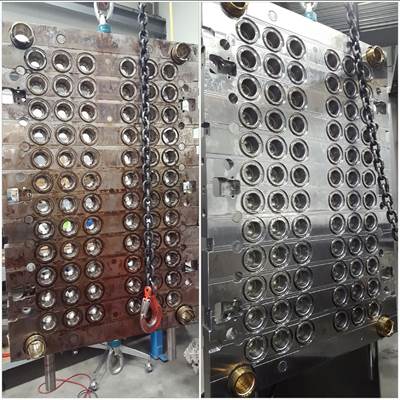

Read MoreConvenient Corrosion Protection for Proper Mold Care

Cortec’s EcoAir easy-to-use rust preventative spray enables injection molders and mold and die-makers to properly care for stored or in-use molds.

Read MorePrecision Metal 3D Printing Technology for Mold Manufacture

Mantle’s P-200 3D printer, combined with the TruShape process, achieves high-performance part production with shorter lead times and lower costs.

Read MoreLive Tool Expansion for Cutting Tool Tightening Options

North American importer Platinum Tooling offers Heimatec live tools for the Hass BMT turret to ensure more rigid mold machining operations.

Read MoreHot Runner Technologies Advance Quality Surface Requirements in Automotive

Oerlikon HRSflow hot runner systems combine cost-efficient production with a precise process control for a variety of automotive applications.

Read MoreHot Runner Manifold Offers Increased Flexibility

Hasco’s additively manufactured Steamrunner hot runner manifold allows for increased flexibility with injection molding.

Read MoreGlobal Moldmaker’s In-House Services Address Mold Design to Part Production

Socem ED S.A. is a mold engineering solutions provider, with capabilities covering mold design, engineering, prototyping and maintenance and repair via a variety of in-house equipment.

Read MoreBenchmarking, Networking Resources for Mold Manufacturers

The American Mold Builders Association provides the U.S. moldmaking industry various benchmarking reports, publications and networking events.

Read MoreUltrasonic Cleaning Equipment Cleans all Mold Sizes

Fisa North America brings nonabrasive cleaning to the mold maintenance forefront, removing oil, grease, colorants, gassing and more in as little as 20 minutes.

Read MoreAdvanced Engineering Solutions for Molds, Plastics

AES Moldes Lda is a mold manufacturing and tool engineering organization operating in three continents to meet its customer’s mold production and management needs.

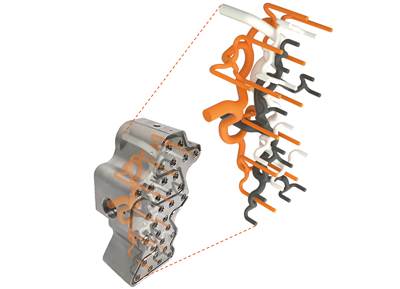

WatchEjector Portfolio Expansion Takes on Demolding Challenges

A number of ejector pins, sleeves and flat injectors, as well as an online ejector configurator have been added by Hasco for the functional demolding of molded parts.

Read More

.jpg;maxWidth=300;quality=90)