Hot Runner Manifold Offers Increased Flexibility

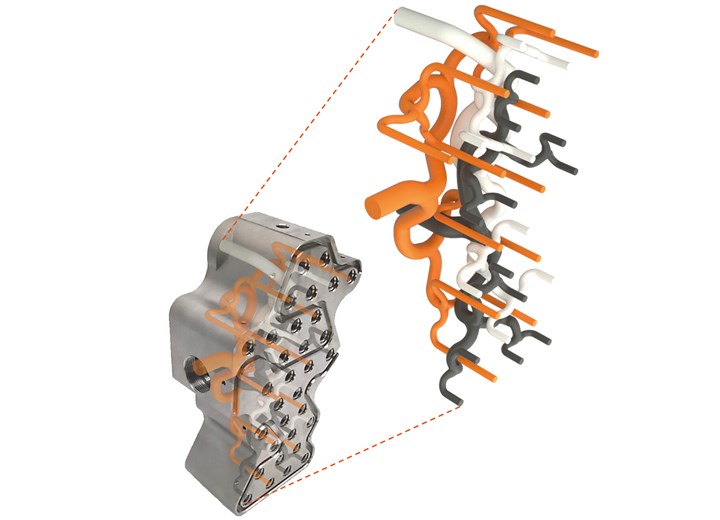

Hasco’s additively manufactured Steamrunner hot runner manifold allows for increased flexibility with injection molding.

Hasco’s Steamrunner is the culmination of the company’s move into additive manufacturing for hot runner manifolds, which it first started back in 2016.

The company says that as an additively manufactured hot running manifold, the Steamrunner offers moldmakers and injection molders unprecedented freedom in design. Using this technology, manufacturers can configure flow channels with optimum rheological layouts, avoiding sharp edges and areas with poor flow. Hasco says the gentle passage of the melt through the manifold makes for considerably lower shear stress in the material, resulting in better quality moldings. It also says the flow-optimized design speeds up color changes, since the melt can be divided and deflected over generous radii. Moreover, the mass channels’ 3D design enables different plastic components or colors to be distributed in a very small space and the channels can be intertwined.

The complete absence of diverting elements allows for production of the Streamrunner in compact designs. Tight spacing down to 18 mm is also possible for high-cavity systems, depending on the application in question. A minimum height of 26 mm makes the manifold considerably smaller than other manifolds on the market, and separately controlled nozzles increase flexibility. Specialists at Hasco hot runner can also employ simulation-based analyses to configure specific solutions tailored to individual assignments.

Steamrunner can be individually adapted in terms of shape and size for the respective application. On request, this is also available as a fully wired built-in system or as a completely assembled hot half with precisely matched control technology.

New developments for the technology are tested in-house in Hasco’s own technical center and continuously optimized.

Related Content

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.