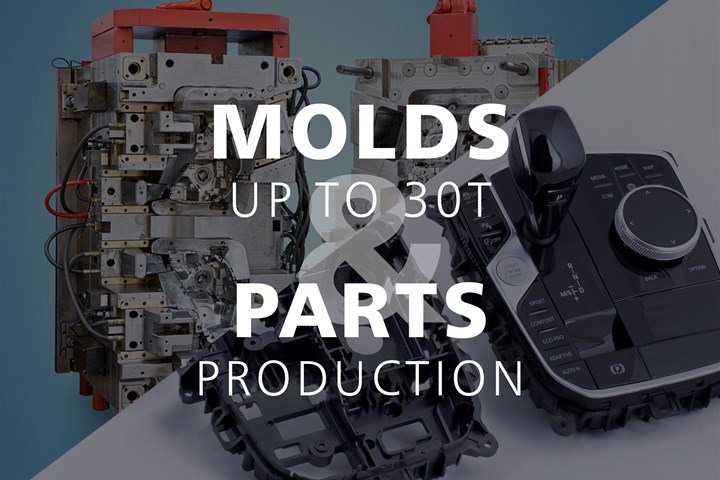

Global Moldmaker’s In-House Services Address Mold Design to Part Production

Socem ED S.A. is a mold engineering solutions provider, with capabilities covering mold design, engineering, prototyping and maintenance and repair via a variety of in-house equipment.

Socem ED S.A., ISO 9001:2015- and IATF 16949:2016 -certified, boasts more than 35 years of experience in the moldmaking industry, with in-house capabilities covering design, engineering, CAE, prototyping, injection molds, graining, checking fixtures, end of arm tooling (EOAT) and low to mass production. The company has also also developed its own global network of enterprises strategically placed in Portugal, Brazil, Mexico and China.

Well equipped with the best available machinery as well as a specialized workforce, Socem says it can produce several types of molds such as: gas-assisted molds, low-pressure, multi-k injection molds and multi-cavitation injection molds, thin wall molds and in-mold decoration (IMD). Socem has seven injection molding machines available, from 90-2,300 tons for trial and serial production.

Prototype mold production and additive manufacturing (AM) technologies are additional capabilities. Prototype molds include silicone molds, molds for RIM production, and prototype molds in epoxy resin with aluminum load. Additive technologies involve direct metal laser sintering (DMLS), multijet printing (MJP), stereolithography (SLA) and selective laser sintering (SLS).

The company also provides technical assistance to ensure preventative and corrective maintenance, as well as the implementation of engineering changes in molds. Socem can perform surface finishing and mold maintenance, including polishing (technical or optical polish, high-gloss and nano-finish), mechanical and chemical engravings (zinc engravings for mold identification plates and coolings and more), and chemical and abrasive grainings (grain patterns such as cork and wood, or VDI graining application are possible).

Socem also retains a specialized team in engineering and development, metrology and GD&T, offering complete solutions in control, measurement and assembly, as well as engineering and development of EOAT.

.jpg;maxWidth=300;quality=90)