Zeiss Receives ACEC Award for Wixom Quality Excellence Center

The new facility features a customer proof-of-capability demonstration area, access to comprehensive training, support and metrology services and more, with a grand opening set for summer/fall of 2021.

Quality Excellence Center in Wixom, Michigan. Photo Credit: Zeiss

Zeiss Industrial Quality Solutions (Maple Grove, Minnesota) announced on March 4 that it has opened its Quality Excellence Center in Wixom, Michigan, to demonstrate that interconnectivity with a modern work environment and state-of-the-art setting enhances insight into quality assurance for customers. The new facility has been reportedly honored by the American Council of Engineering Companies of Michigan (ACEC/M, Lansing) with an Engineering Honorable Conceptor Award for the 2021 Engineering & Surveying Excellence Awards Competition.

The Engineering & Surveying Excellence Awards recognize outstanding projects, honor industry leaders and present scholarships to the next generation of engineering talent. According to the company, ACEC recognized Zeiss and its goal for applying holistic engineering disciplines to the design of its new facility, located in the Detroit metro area.

“Like Zeiss’ products, the design of this facility is taut and precise. Its sleek silhouette is reflective of the company's strong, collaborative workforce and brand identity, and provides the exacting conditions needed to test and operate Zeiss equipment,” shares Bob Varga, AIA, LEED AP, project designer for SmithGroup (Detriot, Michigan), the architect and engineering firm responsible for the project. The result, says Zeiss, is a new standard in designing sophisticated lab systems while simultaneously using strategies to improve the user experience. During the virtual Engineer & Surveying Excellence Awards Gala which took place February 26, 2021, the building also qualified for the 2021 Grand Conceptor Award. This award signifies the year's best overall engineering achievement and will be announced during the upcoming virtual Engineering Excellence Awards Gala, scheduled for June 17, 2021.

Zeiss says its goal is to always provide smarter working environments for better results.

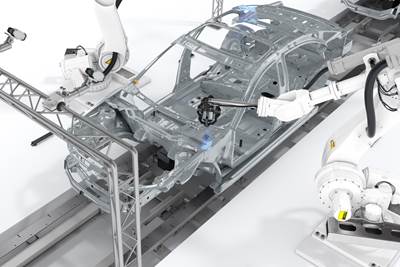

The new Zeiss Quality Excellence Center features a customer demonstration area with new technologies and systems. Customers are able to gain access to comprehensive training, support and metrology services. The center's broad portfolio of dimensional metrology and inspection equipment and services cover a wide variety of industries and applications, including automotive (including car body and powertrain), new energy vehicles, medical, aerospace and defense, additive manufacturing, electronics, visual inspection and general manufacturing.

The quality inspection area. Photo Credit: Zeiss

Zeiss measuring specialists can also perform proof-of-capability demonstrations for multidimensional measurement equipment, surface form and geometry equipment, and non-destructive testing (NDT) and surface defect detection equipment.

Reducing the center's carbon footprint was also a key consideration that went hand in hand with the user experience. “As sustainability is one of our core values, we wanted to make sure that our green spaces adhered to the Zeiss tradition,” says Michael Kirchner, president of Zeiss Industrial Quality Solutions. “We are utilizing solar power to support our facility and have EUV charging stations for our employees and guests. We also produce large systems and measure very large components for our customers, so access and transport paths had to be optimized.”

Kirchner accepted the Engineering Honorable Conceptor Award during a virtual event broadcast on February 26. “I would like to thank the American Council of Engineering Companies for recognizing our new building project,” said Kirchner during his acceptance speech. “This project perfectly reflects our identity and is a great representation of the Zeiss brand, both leading and precise. It demonstrates exemplary engineering design by the SmithGroup along with inspiring concepts for our staff and customers. The elevated workplace environment encourages creativity, innovation, collaboration and offers comfortable and efficient customer spaces.”

Zeiss says its goal is to always provide smarter working environments for better results. The company looks forward to many years of serving and supporting North American customers with the Wixom Quality Excellence Center.

The facility is currently open for essential business including metrology services, training and product demonstrations. A grand opening event will take place in the late summer/fall of 2021 or as soon as COVID-19 safety is assured.

Related Content

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreBreaking Down 3D Scanning in Moldmaking

Identifying 3D scanning requirements and implementing the appropriate technology.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Correlation-Free Measuring Cell Enables Real-Time Process Monitoring

Zeiss Industrial Quality Solutions introduces its Zeiss AICell trace, a dual, 7-axis robotic system that can be utilized in near-line, at-line or in-line applications.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More