Correlation-Free Measuring Cell Enables Real-Time Process Monitoring

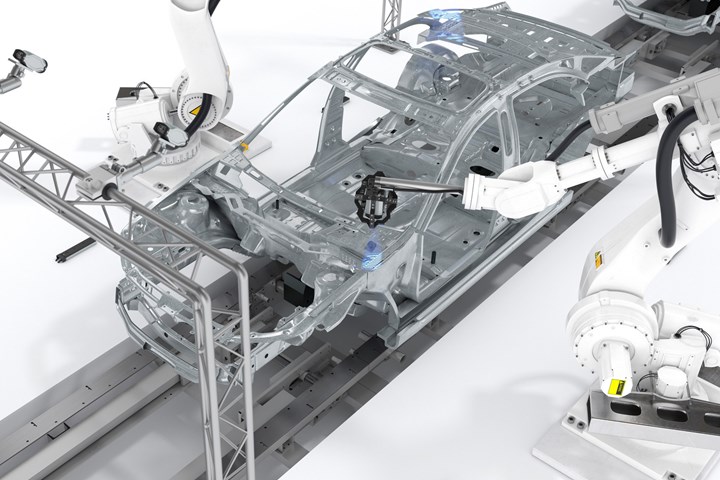

Zeiss Industrial Quality Solutions introduces its Zeiss AICell trace, a dual, 7-axis robotic system that can be utilized in near-line, at-line or in-line applications.

Photo Credit: Zeiss Industrial Quality Systems

Zeiss Industrial Quality Solutions introduces its Zeiss AICell trace, a correlation-free measuring cell. A highly accurate shopfloor car body robotic process and quality control system, the cell achieves ISO 10360-8 stated accuracies while operating in extreme environments and offers what the company says is the industry's widest temperature operating range.

According to Zeiss, the dual, 7-axis robotic system was designed to measure 400 dimensional features faster than any other system in its class. It can also measure 60 critical features in typical automotive cycle times with accuracies comparable to a CMM. Zeiss AICell trace can be further utilized in near-line, at-line or in-line applications, accommodating the most demanding production cycle times and quality initiatives.

Zeiss AICell trace is an absolute system. Zeiss says it requires no correlation offset, which allows it to provide CMM quality results in-line on every manufactured part. Additionally, the system can accommodate all hang-on and body-in-white parts when operating in by-pass mode. The full turnkey system includes Zeiss AIMax cloud optical 3D sensor, Zeiss AICell trace precision robot tracking system, Zeiss CARFIT smart fixtures and turnkey support from the Zeiss engineering team.

According to the company, the system utilizes the high-speed AIMax cloud sensor and Zeiss AICell trace robot tracking technology to accurately dimension critical features including hemmed edges, studs, rivets and nuts behind metal. The system tracks the robot position in microns and measures dimensions in less than one second per feature. The CARFIT smart fixtures with embedded identification and tracking technology automatically identify which part is in the cell to be measured, and the fixture system instantly brings the part into the car body coordinate system.

For more information on Zeiss AICell trace technology visit: AICell trace

Related Content

-

Specialist Automotive Mold Builder Mentors in Work and Life Skills

Southeastern mold builder PFAFF Molds sets the standard in toolmaking for automotive window and vehicle body sealing systems through knowledge-sharing and automation.

-

Mold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

-

Industry Report: Automotive Outlook, Forecast, Disruptions and Industry Transitions

A recent presentation by Auto Forecast Solutions shares some interesting trends to help those who work within the automotive industry better understand key trends.