MMT Blog

U.S. Vehicle Sales Strong in January Bodes Well for Moldmakers

There are a couple of newly-emerging trends that bode well for North American moldmakers if they continue. The first is a trend toward more parts made of plastic or composite materials, which results in vehicles that are lighter weight and less expensive to build. The second trend that will be positive for domestic mold shops is that the domestic automakers are taking market share away from imported models. Read more.

Read MoreAnother MoldMaking Technology Top 10 T-shirt Sighting

This time it went to a Charles Robel—the latest recipient of the “Outstanding Student” Award at Waukesha County Technical College. Along with the title and MMT tee, he was awarded a toolbox donated by The Tool, Die, & Machining Association of Wisconsin and MSC Industrial Supplies from their “Tools To Succeed” program.

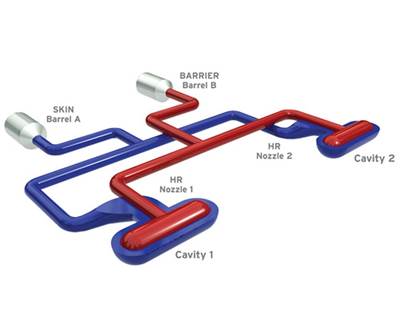

Read MoreIt’s Time to Reevaluate Co-Injection Technology

With the development of new resins, hot runners and controls technology, co-injection is positioned to move from a niche market application to mainstream acceptance in the upcoming years.

Read MoreA “Run for the Border” Expands Transportation Market Niche

“This opportunity demonstrates how a great relationship can develop into a partnership with customers, as we’ve become very much a value-added supplier to them. We’re co-located with them and that strategy lends itself to other OEMs looking for similar relationships.”

Read MoreImprove Input Quality with the Right Tool Inspection and Monitoring System

Integrating efficient tool inspection before and after the cut with optimized tool performance in the cut improves mold manufacture’s efficiency and profitability.

Read MoreInspection/Measurement Advances Yield Better Molds Faster

A roundtable discussion of the latest trends and developments in mold inspection and measurement technology highlights the cycle time reduction, accuracy improvement and cost decrease benefits.

Read MoreTips for Successful Hard Milling of Complex Molds

And when mold and die applications demand hard milling of materials up to 66 HRC, using the right end mills, cutting parameters and machining methods is critical for success.

WatchReshoring Efforts Conquer Time-to-Market Crunch

Challenges in time compression, complexity, communication and cost force project back to the States.

Read MoreAdvanced Manufacturing Consortium: Addressing the Skilled Labor Shortage

“Programs like these are working on rebranding manufacturing into a more computerized and clean environment views—and most important—jobs that will lead to other careers, such as designing, supervision, quality and/or leadership.”

Read More

.jpg;maxWidth=400;quality=70)