MMT Blog

Your Eyes and Ears at Euromold

Here’s a sampling of the technology that caught my eye at the annual tooling, design and application development exhibition in Frankfurt, Germany.

Read MoreVIDEO: You Can't Afford Not to Do It

MMT has covered Ameritech, Steve Rotman and even Apprenticeship 2000 before, but recently all three made it onto a national news program, shedding much needed light onto the value and benefits of manufacturing jobs and one successful recruitment method.

Read MoreWhere Do You Get Your Information?

More importantly, how do your colleagues, customers and competitors stay up-to-date on the latest technology and industry developments? The annual “Media Use in Manufacturing” survey aims to find out.

Read MoreEarly Resolution for 2015

To date, industry donations to iWarriors--a nonprofit organization founded in 2011 by Tim and Kim Bartz of Mold Craft--have helped to supply more than 260 combat wounded veterans with iPads, so they can keep in touch with friends and loved ones as they recover and rehabilitate. Today they announce the 2015 iWarriors challenge. Can you help them achieve the goal?

Read MoreMMT's December Digital Edition Is Now Available

MoldMaking Technology's December issue highlights technology features on designing the optimal cooling system, unconventional strategies for roughing, maximizing process efficiency, the pitfalls of press work and much more.

Read MorePlanning for Success

A consultant that helped one shop improve quote-capture rate by more than 50 percent offers his take on what makes a business plan successful.

Read MoreShare Your Shirts

Readers continue to snap pictures of themselves and their teams wearing MMT's "Top 10 Reasons to Be a Moldmaker" t-shirts from amerimold 2014.

Read MoreNozzle-tip Details Without the Effort

To save customers time and money, this supplier of runnerless molding systems often modifies nozzle tip geometry to suit individual applications. In some cases, this work has led to the development of new, standard tip-style offerings.

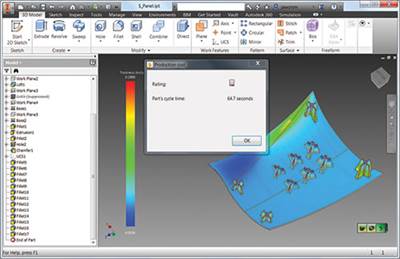

Read MoreMaximize Process Efficiency

Cooling simulation tools can help companies evaluate thermal management early to make informed decisions that will lead to reduced risk downstream.

WatchMulti-Flute and High-Feed

With the right cutter and dynamic cycles, shops can increase metal removal rates by as much as 500 percent compared to traditional machining methods.

Read MoreIn the Trenches: The Pitfalls of Press Work

Consider these factors when deciding on the location of a tool repair.

Read MoreIdentifying and Examining Training Constraints

Finding, Training & Retaining Employees, Part 13

Read More