MMT Blog

SLIDESHOW: Technology Showcase, After K

By all accounts K 2016 was a success. According to show management, attendees were delighted with the wealth of new technical developments presented by raw materials producers, machinery manufacturers and producers of semi-finished and technical parts. Here are some technology highlights.

Read MoreYou Don’t Have to be a Big Company to Make a Big Impact on Your Community

New AMBA educational outreach program promotes the sharing of ideas and strengthens communities.

Read MoreThrowback Thursday: Mold Side-Actions

Demands for improved quality, lower costs, shorter production times and increased part complexity persist, so this two-part series on thinking "outside of the box" when it comes to side-action methods is still very relevant.

Read MoreMold Builders Express Positive Outlook as Work ‘On Hold’ Decreases

OESA and Harbour Results release their Q2 2016 Automotive Tooling Barometer data. While the industry experienced a slow start to the year with more than $2 billion in tooling capacity not leveraged during the first quarter, it has since taken a turn in the right direction.

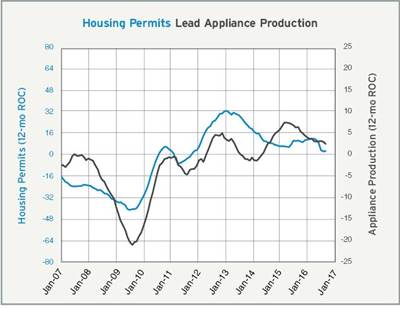

Read MoreAppliances and Packaging

Appliance production should grow faster mid-2017, and strong food/beverage spending should increase packaging demand.

Read MoreKeeping Up with ISO: Applying Total Quality to Sales

Applying the principles of ISO 9001:2015 and the activities of total quality management (TQM) to sales processes can improve the daily operations of any manufacturing facility.

Read MoreCooling of the Sprue

Using conformal cooling in sprue bushing design may be one solution for reducing cycle times.

Read MoreMagnetic Matters

Understanding the benefits and limitations of different magnetic workholding technologies will help ensure that they are used appropriately and to their full potential.

Read MoreUnder the Scope: Communication and Workflow

Closing the communication gap ensures that everyone involved is on the same page, allowing for an efficient and timely repair process.

Read MoreReal-Time Mold Production

An automated five-axis machining/EDM cell offers a cost-effective alternative to series and batch mold manufacturing.

Read MoreIncorporating Robotics

Consider robots in part and mold design, and molding processes to increase part quality and meet growing customer demands.

Read MoreChallenges of Multi-Cavity Co-Injection Molding

Simulation shows that, to be effective, these types of molds must be designed with consideration for how the materials will be distributed throughout them.

Read More