Incorporating Robotics

Consider robots in part and mold design, and molding processes to increase part quality and meet growing customer demands.

Share

Mold builders and injection molders set themselves apart from the competition by how fast they can design and mold a part for their customers. They sell their expertise and capabilities, but equally important—or perhaps more so—are the cycle times they deliver when producing a part. Customers want their projects completed in a timely manner and on budget, and if that is not provided the shop will not get additional work. Meeting those critical requirements ultimately comes down to the automation a mold builder or molder has in place.

It could be said that a shop is only as good as the robots it keeps. Their importance in the entire molding process cannot be emphasized enough. Their role in effective part and mold design, as well as in the actual building of the mold, are essential to engineering out cost, engineering in quality and producing a well-made part.

Part Design

During the design-for-manufacturability (DFM) phase, it’s critical to align the part design with the automation that can make it happen. This includes assessing the customer’s specifications and applying the principles of DFM to make recommendations that better meet the production and automation requirements. Optimizing automation in this way will help identify improvements that can be made to part designs and production efficiencies, savings opportunities, and projected cycle times.

It is important that the part be released from the mold easily and without damage so that a robot can pick it up and move it to the next phase of the process without interrupting the production cycle. Designing with robotics in mind will ensure quick, clean release from the mold, which becomes an important time-saver as well. If parts released from the mold then hang or have to be re-oriented prior to moving to the next phase of the production process, you have an inefficient process.

Mold Design

Once the part design is determined, the design of the mold needs to complement it. This includes allowing enough room for a robot to maneuver. Auxiliary processes such as in-mold labeling (IML) or in-mold decorating (IMD) require robots to situate these additional elements in the mold before the part can be molded. Accounting for these actions in the mold design is necessary to ensure that the mold and automation work flawlessly together.

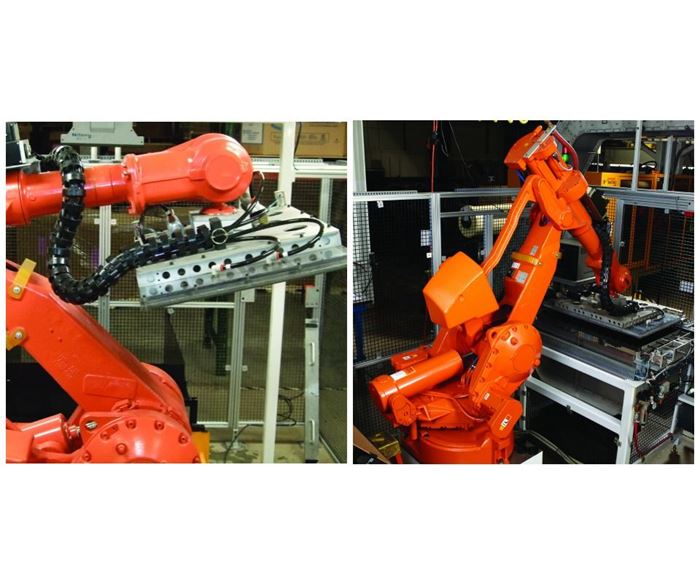

The type of robot to be used in the process will dictate mold design as well. For example, flexible automation, such as a six-axis robot, might provide the freedom of movement necessary for some processes. A robot’s speeds and capabilities can affect cycle times, so it’s important to take automation into account from the beginning of a project.

Upstream and Downstream Processes

Robotics offers benefits in both upstream and downstream processes for producing parts, by way of assisting other, mold-tending robots. They help produce high-quality parts that meet a customer’s key requirements: an innovative solution, a part that exceeds expectations, the right price and a quick turnaround. In upstream processes, robots can be used for actions taken before a part is molded. For example, selecting labels and placing them in position for the mold-tending robots to put them into the mold. Downstream operations occur once the part has been molded and include taking the part from the mold, conducting quality assurance tests to ensure the part is compliant and stacking the part for shipment.

Upstream robotics need to be fast, accurate and flexible in order to manipulate many different variables before a part is actually molded. Here, it helps with pre-staging the required components of a part for the mold-tending robot, which then picks up and places the auxiliary components into the mold. The mold-tending robot ultimately dictates the speed of a job.

However, great speed from a robot won’t mean anything if precision is lacking. High-cavitation molding, for example, requires consistency and repeatability, features that robots clearly can provide, but that are much more difficult for humans to achieve. If a part is inconsistently made because the upstream automation is faulty or lacking, production may be disrupted, costing customers time and money.

Downstream, robotics handle the finished product, conducting quality checks and stacking and/or packaging it. A high-quality and appropriately functioning robot will not release a part to final packaging unless it meets all specifications, potentially bringing the rest of the production to a standstill. Robotics can help implement an extremely high level of quality control to ensure a finished piece meets customer standards.

Continuous Investment

Robotics in both upstream and downstream processes can ensure a steady state of production, resulting in higher quality and more consistent parts. Without continuous investment in robotics and a holistic look at the automation strategy, shops are likely to experience longer cycle times on jobs, which results in higher part costs and reduced part quality.

Robots have become a lot more accessible in manufacturing today, to the point that high-level programmers and/or specialized training are not required to work with the technology. Not considering robotics for daily moldmaking and molding operations can affect the people those shops aim to please: their customers. Having the right automation in place ensures that perfect marriage of speed and precision, giving the customer the part it is expecting at a pace and cost that sets one shop’s operations apart from the rest.

Related Content

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More