Under the Scope: Tackling Tool Welding Problems

This month, we break down common mold repair problems and recommend procedures that welders should consider for mold and die steels.

With every weld repair comes challenges with EDM recast layers, platings, coatings, steel types and filler rod choices. This month, we’ll break down these problems and recommend repair procedures that welders should consider for mold and die steels.

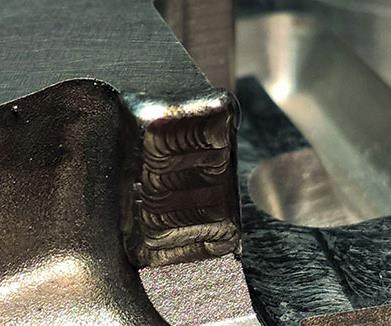

EDM. The EDM process leaves a hardened recast, or “white” layer on the steel surface that can be troublesome for any subsequent weld process, showing microscopic surface cracking and porosity when it is welded. This is true of both laser and micro-TIG welding. Technically, from a tool welder’s standpoint, the only solution to get the best possible weld is to grind down the recast layer. However, this is not always possible, depending on the size of the area being welded and the difficulty of accessing it. For example, some mold inserts are so small that grinding out an area is impractical.

A quicker procedure to weld a recast layer without grinding it out involves increasing the amperage on a micro-TIG machine to burn down that recast layer and adding filler rod. This works, but it requires that the welder increase the amperage to levels much higher than normal to break down the recast layer, which produces a larger welded area and a larger heat-affected zone. In laser welding, the welder moves over the recast layer only on laser pulse without adding rod. Rod is added after the welder is confident the recast layer is sufficiently burnt down.

Of the two types of welding, the burn-down procedure using micro-TIG welding is often more successful, as it offers better penetration of the recast layer. The power output of many laser welders may not be high enough to overcome this layer, depending on the size of the area to be welded and depth of the damage. Keep in mind that, with both procedures, weld pits can still occur. As a rule of thumb, the rougher the EDM recast layer, the more potential for problems. Also, details with inside corners can yield a higher chance of welding pit formation.

Chrome and nickel plating. The optimal process for welding any plated surface is to remove the plating before welding. Of course, this is not always possible. Welding over chrome plating (a treatment used for wear resistance) can pose challenges, such as surface cracking, because the plating is substantially harder than the base steel over which it is applied. For both laser and micro-TIG welding, this becomes a problem when the chrome plating is thicker than a couple thousandths of an inch.

Flash chrome plating (plating of a few ten-thousandths up to a full thousandth of an inch) does not generally inhibit the welding process, because the chrome layer is not as thick, so both micro-TIG and laser welders can weld over flash chrome. However, heavy chrome plating (of a few thousandths of an inch) will pose problems. The basic rule of thumb is: The heavier the chrome plating, the more it will crack and lift from the heat distributed during welding, because it is so much harder than the base steel. Therefore, any chrome plating thicker than a few ten-thousandths of an inch should be removed before welding.

Nickel plating poses a different problem for both micro-TIG and laser welding in that it will melt faster than the base steel during the process, leaving a sunken area where the weld meets the original steel. Similar to with chrome plating, a welder can oftentimes weld over light nickel plating (a few ten-thousandths of an inch), because the amount of nickel is small enough to be absorbed in the weld puddle efficiently, especially in micro-TIG welding. Heavy nickel plating (a few thousandths of an inch) should be removed before welding, because the melting of the nickel will cause a sunken area next to the heat-affected zone.

Nitride. An experienced welder knows instantly that he is working on a piece that has had a nitride treatment, because the area will “pop” and “fizz” during the welding process, leaving miniature holes in the weld puddle. Molds that have gone through the nitride process are difficult to weld because of this resultant porosity. The burn-down procedure to break down an EDM recast layer will not work in this situation. It is best to remove the nitride. Otherwise the customer should be informed that touch-up welds to fix pits may be required.

Steel types. Generally, the welding behavior of tool steels, such as 420SS, H-13 and S-7, is similar. Tool steels, by nature, are quite resilient to temperature changes and shock. For this reason, and depending on the size and the area to be welded, it possible to micro-TIG weld these tool steels without preheating. Laser welding on tool steels also does not require preheating. However, die steels, such as D-2, M-2 and M-4, require post-heat-treatment, since their high Rockwell hardness makes them prone to cracking under any welding process. (Cracking is problematic mainly with TIG welding, but laser welding can also show microscopic surface cracking.) The only way to mitigate potential cracking in die steels from micro-TIG welding is complete pre-and post-heat-treatment. Laser-welded dies may need to have a filler rod applied that is softer than the base steel to reduce the microscopic surface cracking.

Rod choices. Filler rods that are exact matches are not readily available for every steel on the market, so taking a sample of the steel and sending it to a specialty company to have a filler rod created may be necessary. Even with a matching filler rod, however, the same steel hardness may not be achieved unless heat treatment is performed after welding.

For example, with some manufacturers, the filler rod matching D-2 die steel can still be soft (a lower Rockwell hardness) after welding. To achieve optimum hardness, the die may need to be heat-treated after welding. If this poses a problem, the welder can choose another filler rod whose hardness matches that of the base material after welding. Rod suppliers should provide hardness and chemical composition documentation for each rod they carry.

Also, most filler rods for tool steels will come in a regular, hard Rockwell version and a modified, soft Rockwell version. A modified filler rod, like H-13 modified, can be used in place of the harder H-13 version, however, this decision should be made by the customer.

It is important to inquire about the hardness of a filler rod as welded. Keep in mind that if the mold runs an abrasive material, the hardness of the top layer of the weld should match the hardness of the base material.

Next month, we will review mold preparation for welding.

Related Content

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MorePortable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreRead Next

Under the Scope: Understanding the Task

Asking a few simple questions will help the welder prepare for the job at hand to turn it around as quickly and efficiently as possible.

Read MoreUnder the Scope: Considerations for Mold Repair Welding

This new series is intended to arm toolmakers and engineers with the necessary knowledge to make better informed decisions during tool repairs, including an understanding of welding terminology, procedures and challenges.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More