Dramco Tool president Larry Patten started “doing the math” to justify bringing laser welding in-house. Photo Credit, all images: Dramco Tool

Today, Dramco Tool is a 50-person full-service manufacturing shop in the middle of Nebraska, specializing in designing and building plastic injection molds, metal stamping dies, compression molds, composite part tooling, as well as laser cutting, water jet cutting, press brake work and custom machine design and manufacturing—all under one roof.

However, back in 2009, the company lost its primary automotive injection mold customer, changing the course of its future. “They were our bread and butter at about 30% of the business and decided to go to Mexico,” Dramco Tool vice president Larry Patten says. After that loss of injection tooling, Dramco pivoted to aerospace. Then, many years later, Patten got a call from an automotive engineer with whom he used to work. His company needed a tool shop that could build injection molds. This phone call revived Dramco’s injection moldmaking capabilities and expertise.

Patten estimated that the company could potentially increase profits by $50,000 a year if they invest in a laser welder.

Breaking Down Repair

The team, however, was quick to recall how different automotive injection mold work is from aerospace. The tooling work coming in consisted of large rotary injection molds that kept breaking. “We were getting more repair work than new builds,” Patten says. And those differences above are most apparent on the repair side of moldmaking, which quite often needs welding. This meant more reliance on an outsourced welding expert, but even with that increase in repair work, Patten still believed that Dramco did not send out enough welding to justify the cost of buying a machine.

A typical repair for Dramco is about an hour’s worth of weld and it takes three days to complete the job using an outside welding source due to mold transport. Patten used a welder five hours away in Kansas City who was reliable, always available and had welding expertise that Dramco did not. Patten was convinced that his team would not have the necessary skill level if they invested in a laser welder.

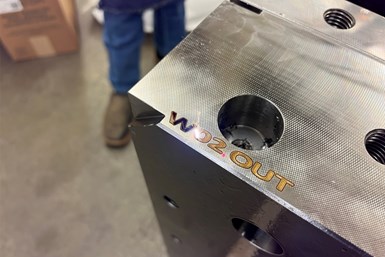

The in-house laser welding system had to meet four criteria: American-made quality, relationships, training and technical support.

Then, Patten started getting pressure from customers to turn the tools around even faster, so he decided to buy a truck. This move cut two days off the turnaround time for each repair, but he still had a feeling the team could do even better.

Patten then decided to build a case to justify the addition of in-house laser welding capabilities. “Can I justify a $150,000 welder when I’m only using it 15 minutes a day? Does that make any sense when you have an expert who can do it?” Patten asks. He started doing the math.

First, he acknowledged that this repair work was endless, so he concentrated on the three days. “Say, we have a 15-minute weld job. Instead of taking three days, we do it in 15 minutes, and we send the truck back to the customer with a completed job sooner. Then the customer loads another job on the truck and we bring it back to the shop to work on. So in the time we typically would have a repair job halfway finished while waiting for the welder to return it to us, with a welder in-house, we now have that mold back to the customer on our truck and we have another mold for repair on the floor,” Patten says.

Patten estimated that they could increase sales for the year by $180,000. For example, they will potentially increase profits by $50,000 a year if they invest in a $150,000 laser welder. “It’s a no-brainer. Once I floated those numbers by my partners, everyone was on board. So, then the question was, where do we go to get a welder?” Patten says.

“We're getting through projects even faster than I had expected. This work has turned into quite a profit center for the shop.”

Making the Investment

Dramco’s decision-making was based on four criteria: American-made quality, relationships, training and technical support. As a result, they invested in an ID1 600-watt fiber laser welder from Alliance Specialties and Laser Sales. According to Patten, this technology is a significant upfront investment, but well worth it.

“The difference between a fiber and a YAG laser is that a fiber laser doesn’t have any consumable materials. There are no lamps, so very little can go wrong. This reduces maintenance costs. It’s also very flexible and portable. You can move it around the shop to weld on inserts and larger tooling. Plus, the learning curve is fast,” Patten says.

It takes skill, but it’s all hand-eye coordination. Patten decided to train employees who never welded and they picked it up in no time. “It’s like playing a video game. You are looking through a microscope and moving a joystick. You can train people in the shop who are not welders, so when they have downtime, they can do some repair work,” Patten notes.

He quickly discovered that repair jobs were getting done much faster, not only because they had the laser welder in-house, but because now Dramco was combining TIG and laser welding, minimizing machining and spotting.

“We tend to hold back when trying to justify a new purchase. And so often, when you make the purchase, you find that it helps in ways that you would never have imagined,” Pattern says. “We're getting through projects even faster than I had expected. This work has turned into quite a profit center for the shop.”

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Career Pathways in High School Produce Better-Prepared Workforce

Several mold manufacturing companies have shared how their workforce development strategies have evolved to meet the needs of today’s industry. Here, Dramco Tool talks about transitioning young workers from a school culture to a shop culture.

Read MoreCAD/CAM Upgrade Boosts Shop’s Efficiency

CAD choice automates and animates, builds customer confidence through communication, and cuts design time in half.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read More