The variety of different products makes moldmaking a constantly evolving field. Finding the right equipment for your application can be difficult, so MoldMaking Technology is here to help relieve the pressure of endless browsing or to just enlighten you with something you might have missed.

Every month, MMT releases a technology roundup highlighting different products, processes and services. This month’s roundup features cutting tools, hot runners, software and more, providing you with a rundown on how these products and services can be useful to you and your applications.

To check out tech roundups from months prior, please browse the “New Tech” section on the MoldMaking Technology website. For more information on a product featured below, click the title link for the respective product.

Related Content

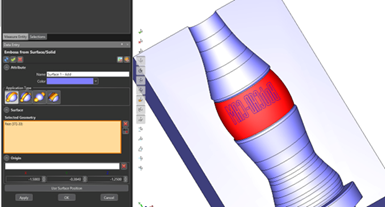

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreRead Next

Metalworking Technologies Targeting Mold Builders

Inspection/measurement, cutting tools, design software, machining and automation equipment round out this technology roundup.

Read MoreTechnology Roundup: The K Show Experience

Catch a glimpse into technologies for plastics, rubber, injection molding, hot runners, sustainability and more being showcased at this year’s K 2022.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)