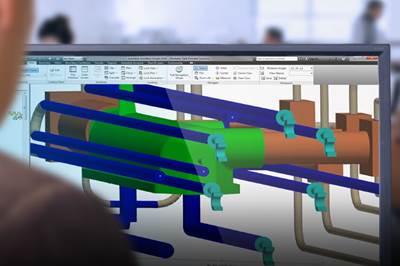

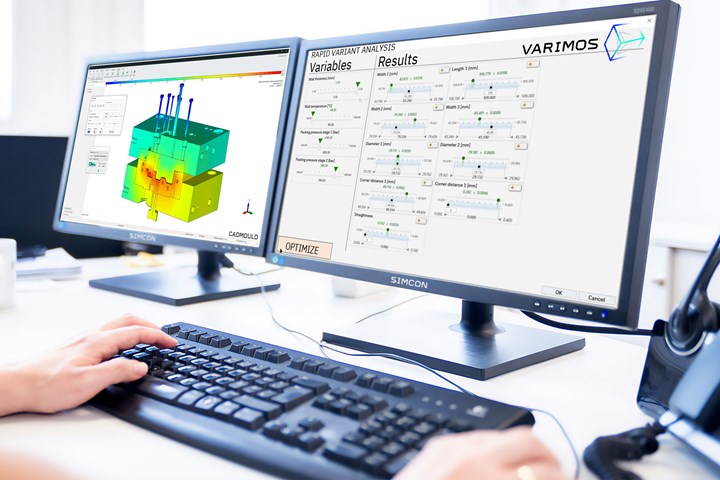

Injection molding simulation software (left) shows a whole-mold thermal analysis and automated injection molding optimization software (right) shows the results of a rapid variant analysis. By moving the “variables” sliders on the left, the user can change settings like wall thicknesses, injection parameters, gate locations, etc. and get real-time updates about simulation results (such as shrinkage and warpage, filling behavior, thermal behavior). Photo Credit, all images: Simcon

After much ado, you’ve finally built your mold. You bite your nails during mold tryouts, only to discover that you have some serious [insert issue that is the bane of your existence: warpage, filling issues, weld lines, surface defects?]. Some vigorous swearing, a healthy dose of stress and expensive mold corrections ensue. “Not again! What can we do to avoid this?” you exclaim in frustration.

At some point, you may have explored simulation and discovered that it does help, but you’ve also found that it’s not a silver bullet. So, here we’ll argue there’s a reason you’re not getting as much value as you may have hoped: Simulation by itself won’t cut it. Instead, you need to change the way you work in part and mold design.

“You’re doing it wrong.” You can have the best tools, but if you use them unwisely, you won't get great results. It’s the same with plastic injection molding simulation.

Ancient wisdom states that if you digitalize a poor process, you will have a poor digital process. Unfortunately, many injection molders will invest a lot into upgrading their software, yet underinvest in upgrading the ways in which they work. As a result, it remains common for would-be innovators to buy the simulation equivalent of a Ferrari and then have it sit in the driveway, just honking the horn and flashing the lights. The point is this: If you upgrade your simulation technology, you must also change how you work, or you won’t get the full value.

Five Important Principles for Process Change

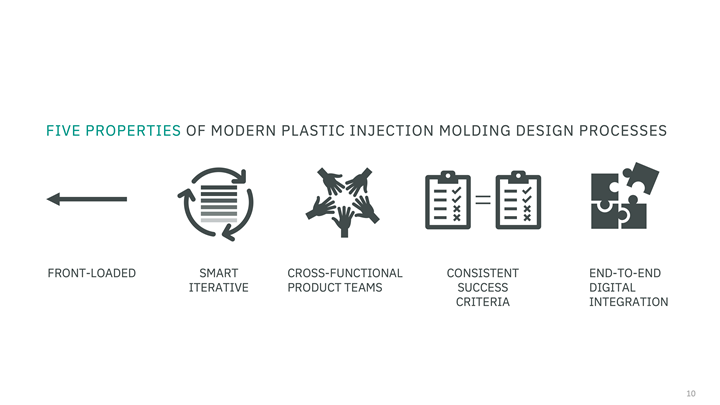

A good way of working follows five critical principles:

1. Front-Loading

This is the obvious one. It means catching and correcting issues early in the process before you build your mold. Yet it is harder to pull off than you might think. To do this well, you’ll need good simulation software and know how to use it.

You’ll use the simulation to determine what will go wrong and evaluate alternative designs. This requires the ability to represent your real-world plans well (because garbage in, garbage out), a high level of accuracy in the simulation engine itself and decision-making institutions that help you turn predictions into insights and decisions. Front-loading is also challenging to do in isolation if you don’t follow the other four principles.

If you upgrade your simulation technology, you must also change how you work, or you won’t get the full value.

2. Smart Iteration

Once you run your initial simulations, you will find some issues that need fixing. How might you go about finding better solutions? One way to do this is trial and error. You tweak your design, run another simulation to check whether that fixes the issue, look at the results, take a second to contain your temper because there are still issues, adjust something else, simulate again and so on. If you’re going to perform trial and error, it’s a good idea to do it in a simulation rather than the real world. However, it’s still an inefficient use of technology.

A smarter way would be to set up a systematic simulated design of experiments (DOE):

- Think hard about the variables you can change. For example, can you change wall thicknesses? By how much? Can you change injection parameters, such as temperatures and pressures? By how much? Collect these variables, then specify a range for each variable.

- Use a DOE design system to turn these variables and ranges into a set of simulations to run.

- Solve these simulation variants, but solve them in parallel, not one after the other. Harness the power of parallel processing.

- Use an analysis tool to summarize results and learn across simulations, so you don’t need to compare them one by one.

This is what smart iteration is: Run a bunch of variants, but look at the whole solution space in a simultaneous unified, integrated way. You’ll get to cause and effect much faster than if you gather evidence piecemeal, comparing individual simulation after simulation, step by step. If you set this up in an automated fashion, you will create a proper simulation factory that pumps out causal insights. This way, after just one iteration (instead of 10), you will already know what variables matter and how to set them to fix your mold issues.

If you want to accelerate your part and mold design, while simultaneously improving quality, you’re going to need to upgrade more than your software. You need to upgrade your way of working.

3. Cross-Functional Product Teams

To make front-loading work, you must know at the upstream stage what will go wrong downstream. A good simulation will predict what will happen, but you also need to know whether that is a problem and what to do about it. So, show your simulation results to your downstream colleagues. For example, if you are a part designer, your downstream colleagues might be your moldmaker, machine operator and metrology coworker.

While it can be cumbersome to make such meetings happen across the different kingdoms inside your shop, it is well worth it. You will catch more issues that are apparent to a moldmaker or machine operator that may not be immediately obvious to a part designer, and you will come up with better all-things-considered ideas for fixing these issues. If you don’t yet know who these colleagues will be, either change your way of working to determine this earlier or include colleagues with that skill set, even if they won’t be the ones who will ultimately take that role.

Good cross-functional collaboration is one of the most critical requirements for true front-loading. First, unless your downstream colleagues are involved early on, you will miss issues that are obvious to them, which will often require changes down the line, counteracting your front-loading ambition. Second, even if you did catch most of these issues, failing to involve colleagues early in the process creates an incentive to change something downstream. If that is the first time you are heard, then that is the only place you can show value. If colleagues are included earlier, there is less need to “prove their value” by introducing changes later.

Good cross-functional collaboration is one of the most critical requirements for true front-loading.

4. Consistent Success Criteria

To enable successful collaboration across functions, a common understanding of the objectives shared upstream and downstream needs to be shared. Without this, it will be hard to achieve good cross-functional collaboration. In addition, if you disagree on how to measure success, you’ll have trouble fostering consensus. As a result, the likelihood of costly changes further downstream will increase dramatically.

5. End-to-End Digital Integration

Cross-functional teams will collaborate more easily if their digital tools work together seamlessly. For example, CAD part and mold designs need to be handed over smoothly to simulation and optimization software, which in turn needs to be compatible with your structural solvers, injection molding machines, metrology software, etc. Deeper connectivity than “just” exporting results is helpful. For example, quality criteria can be included in the digital handovers so that each software along the way uses the same consistent success criteria without causing double the work of recreating them.

In theory, theory and practice are the same. In practice, they aren’t. These five principles may seem self-evident when you think about them, yet many organizations struggle to properly implement them. The ones that do manage to significantly outperform their peers on many key metrics — ranging from the number of corrections per mold to production cost to time to market.

This barely skims the surface of what it takes to apply these principles in the real world. For example, the point on cross-functional collaboration, in particular, requires management engagement and intervention — it’s tough to create cross-functional collaboration “bottom-up” unless the boss is involved. But we’ll talk more about that later.

Related Content

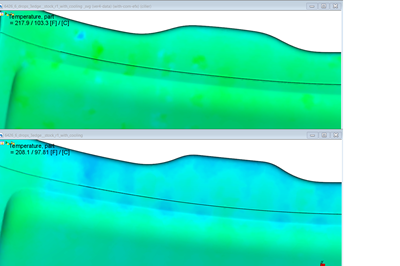

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreHow a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

Read MoreRead Next

Upfront Decisions Matter! It’s About Making Better Decisions Sooner

This free archived webinar covers how to use simulation to reduce manufacturing risk, to optimize performance and to directly get from art to part without iterative changes.

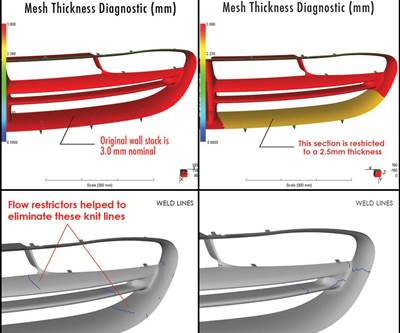

Read MoreDesigning Flow Leaders and Restrictors

Use simulation to control flow in your injection molds.

Read MoreQuickly Troubleshoot New Molding Defect with Moldfilling Software

SyBridge Technologies analyst compares original, new Moldflow process simulation results, solves molding defect without tool needing to be taken out of production.

Read More