As manufacturers accept and implement new technologies into their operations, downstream processes often need to be adjusted to accommodate the type of work that then comes down the pipeline.

One example is additive manufacturing or 3D printing. While many of the first commercial 3D parts were for specialty aerospace and medical applications, the technology slowly but surely has crept into much broader manufacturing settings, including the mold and die industries.

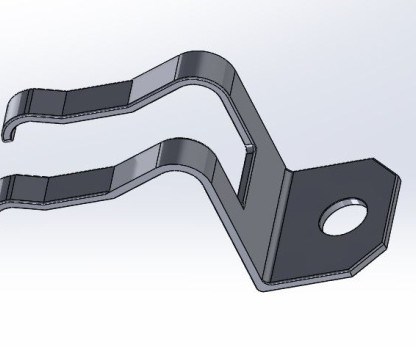

Because of the unprecedented nature of 3D printing, these adjustments touch all areas of machining processes. This article examines the impact of 3D printing on EDM and specifically the impact on wire EDM workholding, cutting conditions and machine-tool specifications.

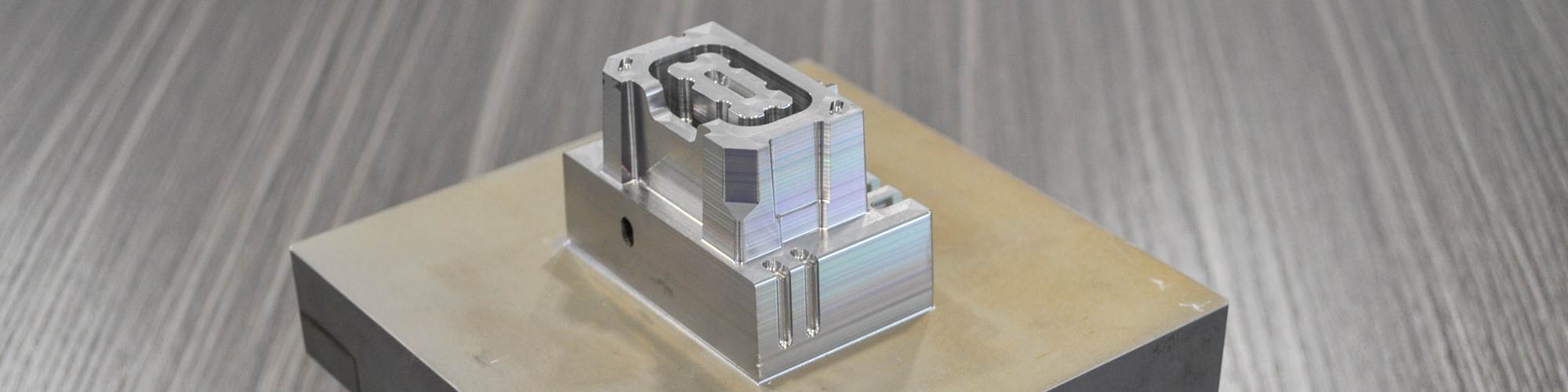

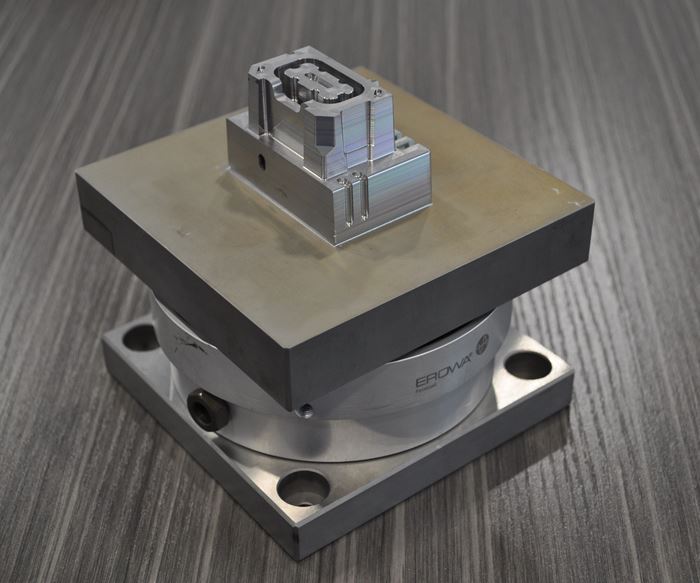

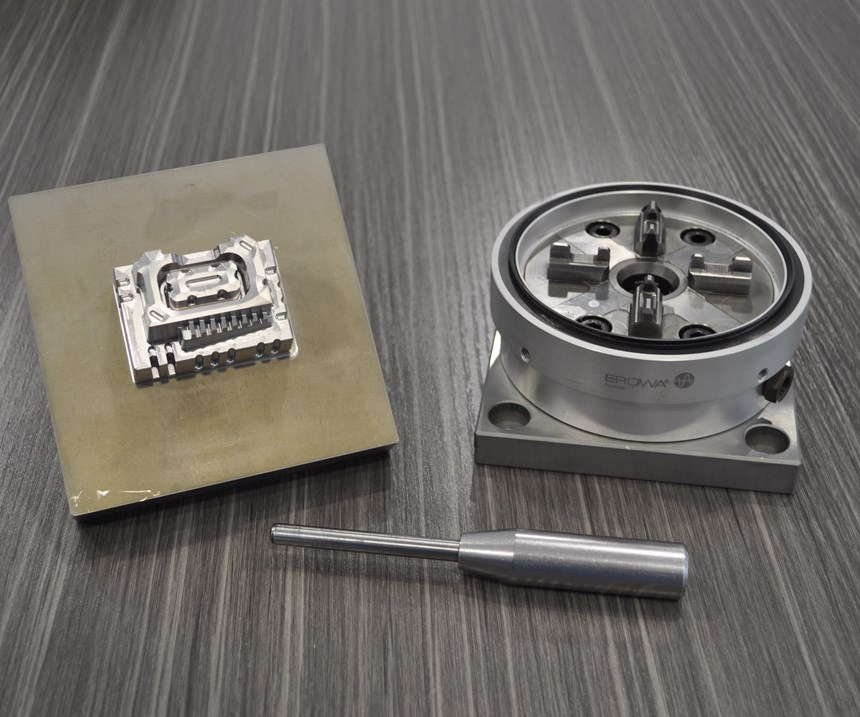

Workholding

One of the most basic considerations before a technician prints a 3D part is how subsequent processes are affected by early workholding decisions. One factor that complicates these decisions is the great variance in 3D printers. Some additive machine manufacturers come from the machine-tool world and have quickly leveraged that experience to provide easy solutions just as they would with a traditional CNC machine. Conversely, those that have led innovation specifically in 3D printing often have less experience with questions pertaining to workholding and so may require more ingenuity to strategize secondary operations.

Naturally, one trend that is taking root quickly is for traditional tooling suppliers to partner with original equipment manufacturers (OEMs) for machines to provide integrated solutions. With validated systems at the OEM level, it is possible for tooling manufacturers to make the secondary operations just a little less laborious. Alternatively, for machinery without an established tooling solution, it may be possible to produce tombstones or other custom fixtures to expedite the setup process, though these would be less transferable from one operation to the next. For example, a part that requires both wire EDM removal and sinker EDM finishing likely would not be able to use a tombstone for both.

Moreover, operators should be aware that because 3D printing is not a perfectly accurate process, virtually all applications would still benefit from the inclusion of reference or datum surfaces for more accurate pickups.

Operators can avoid wire breaks by strategizing their choice of wire.

Cutting Conditions

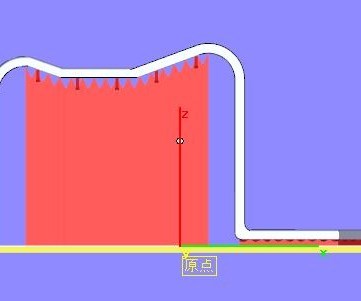

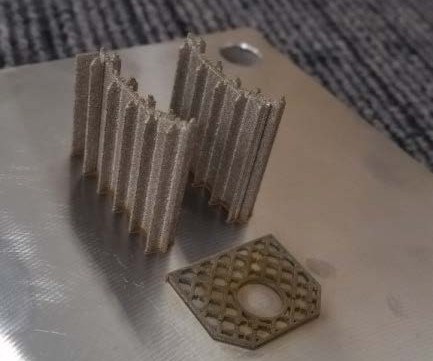

As anyone who has wire-cut into a 3D-printed part would attest, special care is necessary to avoid wire breaks, which typically result from a combination of hollow spaces designed into 3D parts and loose powder that has not been sintered, which often coats and fills these parts. While flushing is important in all EDM applications, it is especially important for additive parts. Inside a typical kerf, flushing jets are confined, which makes it possible for fluid to laminate the EDM wire and to clear swarf efficiently and neatly. As the distance from the flushing nozzle increases, this stream becomes more turbulent and less effective. Also, upon hitting an open or hollow cavity within a part, the flushing stream experiences a drop in pressure, expanding the flushing path and creating even more turbulence to disrupt flushing.

These poor flushing conditions result in an increased concentration of conductive particles that linger within the spark gap rather than being flushed away. These conductive particles continue to spark with each pulse, wearing the EDM wire more quickly than it would under better circumstances. Add to this the loose metal powder that uniquely coats and fills 3D-printed parts, and the operator has even more conductive materials that are not flushed away within these hollow spaces. All of this causes increased wire breaks when cutting additive parts.

Operators can avoid wire breaks by strategizing their choice of wire. Most shops rely heavily on standard, 0.010-inch brass wire, so the goal in troubleshooting is to improve wire breaks over this benchmark. For this type of application, operators can switch to 0.012-inch wire. The larger diameter provides additional strength that keeps the temperature of the wire core low. Others users may switch to steel-core wire, which is much less likely to break under these conditions. However, it is not compatible with most wire-choppers on the market and is more difficult to recycle.

Before buying new wire, however, it may be more cost-effective to explore solutions on the machine control itself. On Japanese controls, the key settings for this case are MAO settings, which more broadly have to do with ON time, OFF time and the sensitivity of adaptive circuits. Increasing the sensitivity of adaptive circuits enables operators most to adjust to more conservative settings on the newer EDM models when the cutting environment is not ideal. One example is when the wire opens a pocket of trapped powder.

Likewise, increasing the OFF time opens more opportunity for the swarf and other debris to clear between electrical pulses. Additional speed can be regained by increasing the ON time, which means that the EDM model will have both longer pulses and longer gaps between pulses. Because adaptive circuits treat ON and OFF time differently, a more sensitive circuit will continue to be conservative even when ON and OFF time are both increased. In broader strokes, the goal is to make the spark environment more conservative while recovering the speed where that is possible.

Shops that plan to take on more additive work may wish to consider machinery that is suited more specifically for this application, as the requirements of an additive part can be quite different.

Machine-Tool Specifications

Additionally, many shops would benefit from reviewing machine specifications in regard to the type of work that they do. Shops that plan to take on more additive work may want to consider machinery that is suited more specifically for this application, as the requirements of an additive part can be quite differently than other processes. Often, wire-EDM work on an additive part is limited to the removal of supports or of a baseplate, meaning that the goal is no longer fine finishing or extreme precision but capacity, cutting speed and reliability under unfavorable conditions.

This change has put equipment manufacturers in a somewhat difficult predicament, as they design around very different specifications than those that the additive market demands. As additive applications continue to grow in size at a fairly rapid pace, the Z height required to machine these parts with EDM also continues to increase.

And yet, while this application does not necessarily require an extreme surface finish and micron accuracy, the only machines capable of accommodating these large workpieces are often the premium, large-capacity models in the EDM lineup. These premium models tend to offer many capabilities that, while impressive, are not strictly necessary for the application at hand, and thus add unnecessary cost. Moving forward, expect EDM manufacturers to introduce models that target the additive marketplace more adequately, with fast cutting speeds and large capacity but without advanced technology for six-, seven- or eight-pass finishes. These machines will be a much better fit for the type of additive work that looms on the horizon without breaking the bank.

The automatic wire threading (AWT) on these machines will be important as well. While additive jobs will often not require numerous fine-start holes (unlike some typical EDM jobs), they will still require a highly capable threader. This is because 3D parts frequently use exotic geometries, hollow cavities and more. These factors, alongside the increased wire breaks on 3D applications, mean that a reliable threader will be a key factor for success.

Look for threaders that are annealing, which keeps the wire straight even through a tall, hollow workpiece. Also verify that AWT performance is reliable even at the full Z height, as operators can expect to see taller work with some frequency.

The growth of additive manufacturing seems poised to benefit mold builders here in the United States, where access to high-end technology may contribute to reshoring. However, the shops that will capture much of this new business will be the shops that recognize new demands and new ways of doing things.

About the Contributors

Evan Syverson is the additive and HSM business manager of Sodick Inc., and Tully Mijatovic is an applications engineer for Sodick Inc.

Related Content

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read More2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreMMT's Most-Viewed Case Studies in 2024

Did you miss any of MoldMaking Technology’s most-viewed case studies from 2024? Now’s your chance to dive into these trending topics.

Read MoreSoft Wired: Cutting High Taper Angles with Wire EDM

Examine the wire’s properties to determine the right one for achieving the best cut.

Read MoreRead Next

Laser Optimization Helps Brings AM to the Next Level

A new productivity-boosting technology, called parallel mode, redefines metal 3D printer process speed.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More