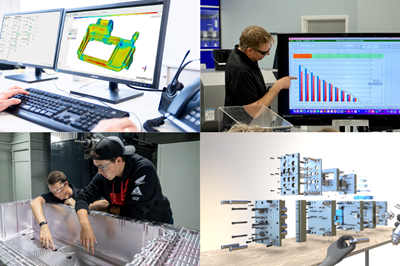

Photo credit, clockwise from top left: Ellwood Specialty Steel, Molder’s World, International Mold Steel and Edro Engineering and Specialty Steels.

The Plastics Technology Expo (PTXPO), taking place this year March 28-30, 2023 at the Donald E. Stephens Convention Center in Rosemont, Illinois, brings partners across the supply chain together, bringing energy and excitement to the show floor.

To provide a little more insight into who our product, equipment or service suppliers are before you arrive at PTXPO, the MMT team put together this special show section* that provides a snapshot of each exhibitor most relevant to moldmaking.

Each profile shares details important to the company’s business and innovations, including why and what they are exhibiting at PTXPO in or around the MoldMaking Pavilion.

Use promo code MMT23 and register today for your FREE exhibit hall pass and we’ll see YOU in Chicago!

*This exhibitor list is subject to change. Current as of 2/2/23

Get to Know Edro Engineering and Specialty Steels

Moldmaking is important to Edro’s business because moldmakers are the company’s key customers in the plastic industry. Servicing mold manufacturers with custom mold bases, unique core and cavity materials and PVD/DLC coatings is something Edro’s team take great pride in.

Photo Credit: Edro Engineering and Specialty Steels

An innovation for the moldmaking marketplace is the company’s RoyAlloy stainless mold base steel. RoyAlloy addresses the shortcomings of traditional 420 pre-hard with its superior dimensional stability, enhanced toughness and machinability.

Be sure to visit Booth 921 and the available technical experts representing all segments to better understand how Edro remains at the forefront of developments in DLC coatings and additive manufacturing (AM). Displays will include mold base manufacturing and mold base steels, Bohler core and cavity steels, MoldMAX copper alloys, aluminum plate and expertise in manufacturing 3D-printed inserts.

**Find Edro in the Injection & Blow Molding Pavilion.

Get to Know International Mold Steel

Moldmaking is important to International Mold Steel (IMS) because the company cuts-to-size, squares, surface grinds, chamfers and laser engraves mold steel. The company appreciate the many products that are created to make our lives better and, most importantly, IMS values the spirit and determination of the people who have made a career in moldmaking.

Photo Credit: International Mold Steel

International Mold Steel was the first mold steel supplier to offer in house double-head squaring services. IMS hopes to continue learning and sharing its innovations with the community in the Moldmaking Pavilion.

The IMS Booth 1228 theme is “Partnerships in mold steel.” The company’s jam is discovering customer application issues and then working together to solve them. NAK55, PX5 and DCMX provide proven technology for extending the life of a mold. DAP-AM HTC powder is now available to intensify the cooling of a mold. Conversations are anticipated, and snacks will be provided, maybe even some bourbon… IMS is based in Kentucky after all.

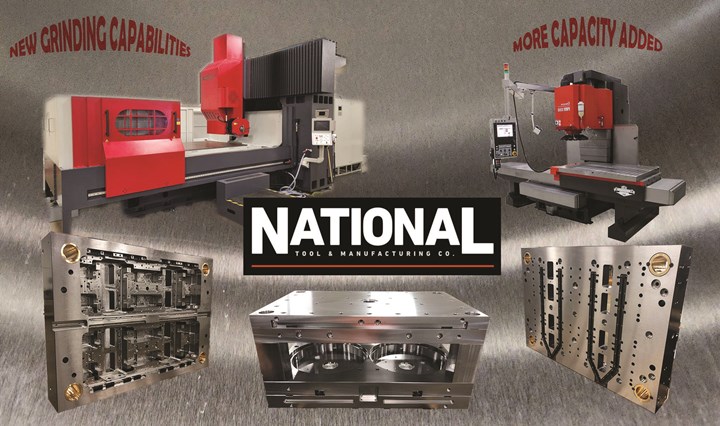

Get to Know National Tool & Manufacturing Co.

National Tool & Manufacturing has played an active role in moldmaking for over 90 years. As the industry continues to advance with new technology and increased precision and delivery demands, National makes its own investments — in precise equipment and highly trained staff — to exceed those demands, supplying U.S. moldmakers with mold bases and mold base steel. One such example is the company’s development and expansion of its VR stainless steel collaboration.

Photo Credit: National Tool & Manufacturing Co.

National Tool’s offering of cost-efficient, premium-quality stainless mold base steel, combined with multiple levels of plate processing, has enabled both smaller and large shops the ability to compete in new arenas globally. Finishing large mold bases and completing additional machining, gundrilling and precision surface grinding has allowed shops to focus on high-value core cavity work for expedited timelines.

Visit Booth 1215 to learn about National’s newest machine acquisitions and fast-to-market offerings, from steel to quick precision machining. Staff available to attendees will include moldmakers and designers.

Related Content

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreRead Next

PTXPO Preview 2023: 3D Printing, Machining and Cutting Tools Technology and Services

The Moldmaking Pavilion powered by Amerimold is one of seven pavilions returning to PTXPO. Take a moment to familiarize yourself with those exhibitors that can fulfill your 3D printing and machining needs.

Read MorePTXPO Preview 2023: Upcoming Software/Simulation Services, Training and Marketing Solutions

This latest installment of PTXPO snapshots feature companies in and around the Moldmaking Pavilion powered by Amerimold that provide industry solutions in software, simulation, training and marketing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More