Precise Tooling Solutions Inc. of Columbus, Indiana, designs, builds and repairs injection tooling, and build and sells adjustable-height workstations and lift tables plus standing barriers for worker protection. The 42-year-old company serves customers in automotive, consumer goods, aerospace/defense, medical device and assembly/materials handling industries.

Photo Credit: Precise Tooling Solutions Inc.

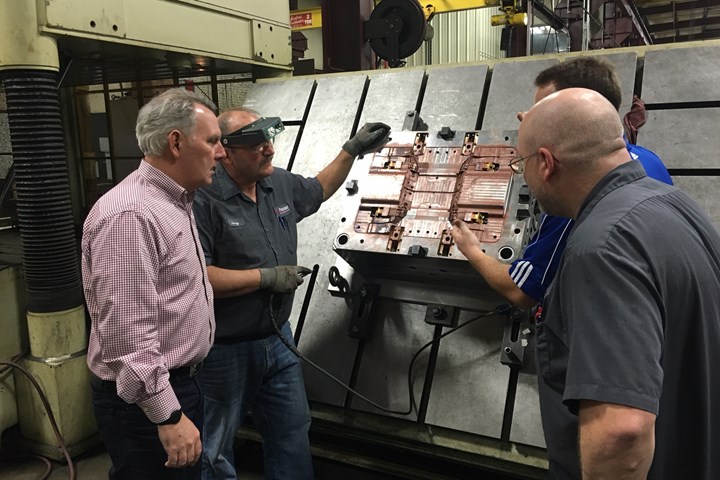

Precise Tooling Solutions Inc. of Columbus, Indiana, designs, builds and repairs injection tooling for both thermoplastic and thermoset molding. The 42-year-old company is known for its expertise in tight-tolerance tools for automotive lighting. It also uses its CNC machining capabilities to produce a variety of machined parts, including its ErgoSmart custom-configured, adjustable-height workstations and lift tables and its ViralBarrier worker-protection barriers. Precise was also MoldMaking Technology’s 2020 Leadtime Leader Award winner.

Quest for Better Data

Almost nine years ago, Precise was acquired by Don Dumoulin, a businessman who had run a number of companies and divisions of large corporations in the medical device and personal care industries. When he joined the team, the company began three major phases of change.

At the time of acquisition, 95% of Precise’s business was producing new injection molds—90% of which were for automotive—so one of Dumoulin’s first tasks, aside from paying down debt, was focusing leadership on diversifying not just markets but also services and products to better weather economic storms. In time, that led to acquisitions like the ErgoSmart line. Progress has been made on diversification, as, presently, new injection molds generate 50% of company revenues and just half of those tools are for automotive.

After making significant investments to replace many of the machines they used daily with new equipment representing the latest technology, the Precise team began searching for a manufacturing analytics system to help management better understand when machines were idle and why. After spending years reviewing products from multiple companies, a chance conversation led to the team learning about a Chicago startup named Amper Technologies with an innovative technology and affordable pricing structure for what has proven to be a very effective OEE tracking and machine monitoring system. Photo Credit: Precise Tooling Solutions

During this same period, the team began installing an enterprise resource planning (ERP) system “to escape Excel hell” as well as working toward ISO certification. “Although none of our customers asked us to get ISO certified, we knew it would give us a language to discuss quality inside the company,” explains Dumoulin, Precise CEO and owner. “That, coupled with the strong foundation our ERP system provided, would allow us to shift our company’s culture from an ‘I think, I feel…’ to ‘The data show…’ approach, which would improve everything from quoting to meeting commitments.” The company achieved ISO 9001:2008 certification in 2016 and 9001:2015 certification in 2019.

“I think every manufacturer needs an operating system that can repeatedly be used to solve problems and build the business. A tool like Amper doesn’t solve your problems on its own, but it facilitates conversations, helps you ask the right questions and can drive cultural change.”

In the second phase, the company made significant capital expenditures to replace many machines they used daily with new equipment representing the latest technology. To support that investment, the team began searching for a manufacturing analytics system to help management better understand when machines were idle and why.

“In this industry, if your spindles aren’t turning and chips aren’t flying, then you’re not making money,” Dumoulin adds. To that end, the team developed a checklist of key attributes they wanted in an overall equipment effectiveness (OEE) tracking and machine monitoring system. They spent the next few years carefully evaluating systems in terms of implementation requirements, ease of use, true cost of implementation, ability to get simple reporting and ability to engage the entire Precise team.

“We evaluated at least five different machine utilization programs and while they were all nice, and had lots of bells and whistles, they also were crazy expensive,” recalls Dumoulin. “They all promised a quick ROI [return on investment], but I couldn’t make the math work when you had to spend thousands of dollars per machine to get data out, and then another $20,000 to $60,000 a year for software licenses. I was very blunt with the CEOs of those companies, telling them their pricing was way out of line for this industry and that they needed to adopt a SaaS [software as a service] business model.” Dumoulin adds that during this period, he sat on the board of another company that switched to a SaaS model and doubled its income in just three years.

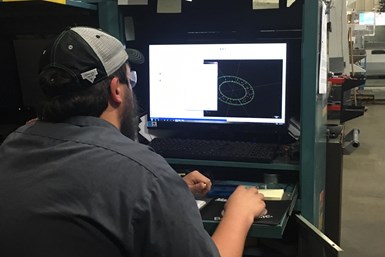

Despite making the quest for proactive rather than reactive business metrics a major focus, the Precise team completed phase two equipment upgrades and started the third phase without finding an OEE monitoring system that met their needs. Meanwhile, the team upgraded their ERP system, moved more computational capabilities to the Cloud and automated more manual operations by installing new CAD software, which saved programming time on various machines that would be used to produce each workpiece.

Just as Dumoulin was about issue a purchase order to one of the manufacturing analytics companies the team had interviewed, a chance conversation with Kevin Rucinski, senior project manager, Great Lakes Trade Adjustment Assistance Center (GLTAAC, Ann Arbor, Michigan) changed everything. (GLTAAC is a federally funded, non-profit providing business assistance to manufacturers in Ohio, Indiana and Michigan that have been directly impacted by offshoring.) Rucinski mentioned he’d seen a new machine monitoring system running at another GLTAAC customer’s plant and thought Dumoulin should take a look. The system was from a Chicago startup called Amper Technologies Inc., and Dumoulin and his team did take a look. The rest, as they say, is history.

Not Your Grandfather’s OEE System

Amper was co-founded in 2016 by Northwestern University computer science graduates Akshat Thirani and Philip House. Ironically, the partners spent their first eight months going in a completely different direction. “We’d been working on a smart circuit breaker to help homeowners monitor energy usage for their house and appliances to help save energy and reduce utility bills,” recalls Thirani, Amper CEO. “Unfortunately, the system proved too complex and we couldn’t launch it.”

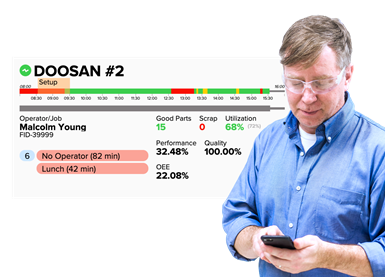

With what Precise has learned from the data it has collected from Amper’s machine monitoring system, the team has been able to make effective changes that have increased machine utilization. These include installing more tool holders on machines prone to delays due to missing tools, ordering more tools sooner (and changing to a different type of cutter) based on tool breakage data, assigning one worker to ensure every machine has all the tools and steel it needs for each shift and having machinists start programming the next job while a machine is still completing its previous job. Photo Credit: Precise Tooling Solutions

As the partners considered Plan B, Thirani’s background in manufacturing kept coming up. He’d spent his youth on the floor of his father’s automotive parts manufacturing plant in India where he learned the pain points manufacturers face every day. As he tells it, “I saw that technology was not always accessible, easy to adopt or democratized, and my passion and personal connection to manufacturing got me thinking about how to make it easier for manufacturers to determine how their machines ran and how their people ran their machines.” Turns out that earlier experience in energy monitoring didn’t go to waste.

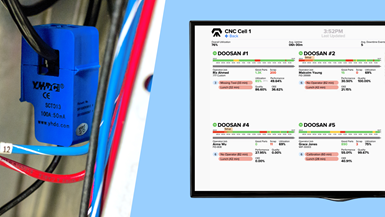

What is Amper? “It’s the simplest machine monitoring and analytics tool out there,” explains Thirani. “We’ve built this system to be as practical and affordable as possible, which is why it’s currently used by small job shops and global corporations around the world. A big benefit of our system is its underlying technology, which uses non-invasive sensors on the outside of machines to measure system amperage or power draw, plus a patent-pending algorithm that maps the strength of those electrical signals to determine when machines are resting and when they’re working. The system is easy to implement, data transfer can be done via the Cloud, WiFi or cellular signals, and yet it provides sophisticated input that can be directly used by all team members.”

A big benefit of our system is its underlying technology, which uses non-invasive sensors on the outside of machines to measure system amperage or power draw, plus a patent-pending algorithm that maps the strength of those electrical signals to determine when machines are resting and when they’re working.

“Our business model is just as simple,” continues Philip House, Amper CTO. “For a flat monthly fee per machine, a manufacturer gets an all-inclusive package covering hardware, the software platform, customer support services, a dedicated account manager and any needed maintenance for the terms of the contract. Most customers achieve ROI in just two months. Companies that are interested but unable to commit until they try the system really like our trial offer, which lets them install Amper on two machines for 30 days at no cost. And earlier this year, we implemented a tiered pricing system. That makes it easier for small companies to start using the system, then add services as they gain experience, but it is also attractive for larger organizations with multiple locations and a need for more customization.”

When the Precise team started exploring Amper’s product and pricing, they found that it met every criteria on their checklist. “We were so surprised but pleased to find someone approaching machine monitoring in a different way,” explains Kyle Rutan, Precise manufacturing manager. “First, with their SaaS business model, there’s no sunk capital while you wait and hope the data you get out can help you. Their simple and affordable pricing makes 100% sense for our industry. Second, the system is so easy to implement that your maintenance team can install both hardware and software in 15 minutes per machine at a time when that machine isn’t running, so there’s no lost productivity. You don’t need a programmer digging around in your machine’s code. Third, their system is essentially machine agnostic and works on old and new equipment. Their algorithm learns the differences in current draw for each type of machine when idling and when running to determine machine status. Their software has lots of useful templates that can generate usable reports as soon as each machine is mapped to the system. If you need to drill down deeper or create customized reports, the system’s flexibility allows that too.”

Actionable Data

Eight months after installing Amper, Precise has made modest changes that have significantly improved machine uptime. By training their machinists to enter accurate codes explaining why a given machine was down, the team quickly understood that three issues accounted for much of their lost productivity: time spent entering programming before a machine could run, machines unable to run because they lacked the right tool and machines waiting for steel to arrive. The new CAD software installed at roughly the same time as Amper is already helping to reduce machine programming. Plus, the machinist begins programming the next job while a machine is still performing its last task, reducing transition time between jobs.

“Comparing average programing time on two of Precise’s machines from April 1 to May 19, 2021 versus May 20 to June 18, 2021, our system recorded a 48% reduction on a Johnford vertical mill and an 81% reduction on a Haas VF-8 vertical machining center,” explains Howard Goldsmith, the Amper account manager assigned to Precise.

Amper is a machine monitoring and analytics tool designed to be practical, easy to install and easy to use. An affordable pricing schedule based on a flat fee per machine per month provides an inclusive package of hardware, software, support and maintenance. Data transfer can be done via the Cloud, WiFi or cellular signals. Amper is said to be ideal for use in discrete manufacturing companies such as tool and die makers, molders and fastener producers. Most customers are currently in the aerospace/defense, medical device and industrial market segments. Photo Credit: Amper Technologies Inc.

Another important change made in response to machines waiting for tools was to install more tool holders and order more cutters earlier. In fact, while looking at tool breakage data with a supplier, that company offered a different cutter that works better for Precise’s use. And third, one person is now responsible for ensuring every machine has all the steel it needs for its next shift and that tool carts are set up ahead of time.

“I think every manufacturer needs an operating system that can repeatedly be used to solve problems and build the business,” Thirani adds. “A tool like Amper doesn’t solve your problems on its own, but it facilitates conversations, helps you ask the right questions and can drive cultural change. At a time when a quarter of Americans are looking to change jobs, manufacturers can’t find enough skilled workers, and companies and individuals are trying to recover from the pandemic, understanding how to increase your equipment’s effectiveness is more important than ever.”

A major difference between Amper’s OEE system and that of competitors is that it uses non-invasive sensors that clip to a machine’s power supply and measure machine amperage or power draw. The sensor data are fed into the system’s patent-pending algorithm, which maps the strength of electrical signals to determine when machines are at rest and when they are working. Operators select codes to indicate why a machine is idle, helping companies better understand the source of machine downtime and take action to improve utilization. Photo Credit: Amper Technologies Inc.

“Machine monitoring is an important tool for continuous improvement because it helps you get to the root cause of what’s hurting your efficiency, and that shows you where opportunities lie and helps you drive better processes,” adds Dumoulin. “With all the challenges mold builders currently face, understanding what actions you can take to meet your daily production goals and improve your projects while also empowering your team and making your managers coaches is a win-win for everyone.”

Related Content

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreRead Next

Snapshot of Why Precise Tooling Solutions is MMT's 2020 Leadtime Leader Winner

Here is a quick look at some of the reasons this small specialty manufacturer took the title this year.

Read MoreLeadtime Leader: Q&A with 2020 Winner Precise Tooling

Hear from 2020 Leadtime Leader Award winner Precise Tooling on the benefits of the Leadtime Leader Award. Now is the time to recognize your shop. It’s not just about being the shop with the shortest delivery times. It’s about what you do with what you have. Enter today!

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=970;quality=90)