Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

We often say that people are our most important asset, but in reality, we scarcely encourage people to grow and use their creative problem-solving skills. People are often given very limited repetitive work to do and are rarely ever asked to participate in their improvement ideas. Toyota and other Japanese companies studying original suggestion systems going back to Kodak in 1898 have changed the way people now participate at work.

In 1981, on a study mission, it was noticed that companies in Japan were receiving close to 50 written suggestions per year per employee, while in America, the average employee submitted one idea every seven years. What were the Japanese doing to get such a response?

Now, even though both the Japanese and American systems were called suggestion systems, they were totally different. The Japanese system has all employees involved in continuous improvement activities, while in America, it is a cost savings system. We don’t want to be bothered with small ideas.

Quick and easy kaizen is one of the more recent ideas to come out of Japan — an idea ripe for consideration by American industry. It is aimed at increasing quality, productivity and worker satisfaction, all from a very grassroots level.

"The basic idea is that each and every company employee is encouraged to come up with ideas — however small — that could improve his/her particular job activity, job environment or any company process for that matter. More importantly, the employees are encouraged to implement their ideas and document them for review and consideration for incorporation wherever the idea might be applicable within the company," states Eugene Ruff-Wagner, C.P.M.

Overseas Examples

At the Canon Camera plant in Japan, there were cameras being assembled. At the time, Canon employees were offering around 50 improvement ideas per year per employee. One clever idea was a wastepaper bucket with small wheels on the bottom. An operator, when finished with her assembly process, put the camera into the bucket and pushed the bucket over to the next operator. Simple, but it saved her time getting up and going over to the next station. It was recognized that something was happening here that was changing the world of manufacturing. And quick and easy kaizen was an essential part of the process that makes the Toyota production system work.

What sets Toyota apart? Its production system is at the heart of everything it does. Based on the concept of continuous improvement, or kaizen, every Toyota team member is empowered with the ability to improve their work environment. This includes everything from quality and safety to the environment and productivity. Improvements and suggestions by team members are the cornerstone of Toyota’s success. If true, why has the U.S. continued to ignore that part of lean?

Toyota expects everyone to participate in suggestion programs, but supervisors take the responsibility to help those workers who have difficulty participating. The supervisor encourages, challenges, suggests and teaches the employee how to implement their ideas.

The Japan Human Relations Association (JHRA) in Tokyo is an organization that was leading the quick and easy kaizen efforts throughout Japan with its training programs, workshops, books and magazines. It only promotes quick and easy kaizen. They dropped all of the other HR functions for they believed that quick and easy kaizen was the best way to develop human resources within a company.

The NHRA in the U.S. has a similar mission to help develop people within a company, but to what extent do they promote anything similar to quick and easy kaizen?

Matsushita (Panasonic), Isuzu, Sanyo and others claim to save more than $3,000 per year per employee. Imagine Panasonic claims more than $175,000,000 was saved in 2002 from its employees’ improvement ideas. Why in the world aren’t we doing this in America?

At Tôhoku Oki Electric Co. of Fukushima, they were getting 570 suggestions per employee per year (roughly two written ideas per employee per workday). This system worked for them, was the center of their success and led all of their improvement efforts.

Bringing It to the United States

At Technicolor Corporation (Detroit, Michigan), they went from receiving 113 implement ideas from 1,800 people in 2001 to 24,000 these last 12 months, and they claim a savings of $8,000,000 from those ideas.

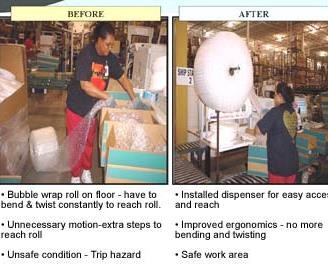

Claudia Washington’s job at Technicolor is to pack videos and DVDs. When reaching for the bubble wrap on the floor, she has to bend and twist to reach the roll. These are unnecessary motions and extra steps to take. It is an unsafe condition, possibly causing her to trip or lead to a repetitive strain injury. Through her quick and easy kaizen training, she was taught to find ways to make her job easier and more interesting.

Figure 1a and 1b. Photo Credit: Technicolor

Her idea was to hang the bubble wrap on a very simple square fixture to eliminate bending and twisting (Figures 1a and b). Just imagine how she felt when she was asked to be creative on the job; told that she did have very goods ideas on how to make her work easier and more interesting; empowered by her supervisors and managers to make the improvements necessary; came up with this creative idea on her own and participated in the improvement. She didn’t just give her idea to someone else to do for her.

Ken Van Gundy with Technicolor notices the new fixture, and a light bulb goes off in his head. He replaces the bubble wrap with inexpensive wrapping paper. Ken then sees that the paper on the square bar when pulled, rolls off unevenly. He replaces the square bar with a round bar. Ken’s next idea is to place a pen at the end of the round bar to prevent the wrapping paper from falling off.

Prior to these four suggestions, two semi-trailers of bubble wrap were delivered to Technicolor each week taking up a lot of shelf space, in addition to forklift drivers constantly moving bubble wrap around the factory.

Claudia and Ken made their work easier, safer and much more interesting and saved their company more than $99,000 a year. It is amazing what can happen when you empower people to be creative at work.

Now, Gary listens. In fact, every day at 4:00 p.m., Gary meets with his immediate staff and they review all the ideas submitted by the employees. Their goal is to give immediate feedback to the employees and see how they can help the employees implement the ideas.

Making It Work

The three objectives of kaizen are participation, development activities and effect. The power behind quick and easy kaizen is contained in the definition of kaizen broken down into three areas below:

- Change the method. This means that once the change is made, you can’t go back to the old way of doing things.

- Kaizen is small ideas. In fact, the smaller, the better. Engineers and managers are constantly coming up with new innovative ideas; they must innovate for the company to survive. Innovation takes time and is costly to implement, but kaizen is just day-to-day, small improvements that when added together represent both enormous savings for the company and enormous self-esteem for the worker.

- Kaizen is done within realist or practical constraints. Often, when change is suggested to supervisors and managers, there are a host of reasons why it can’t be done, including not enough money; not enough time; not enough man/womanpower; too many initiatives going on at this time; the bosses are too busy and won’t allow us to change; too many rules and regulations to overcome; we have to worry about ISO and standardization; the old way is always the best; it is difficult times; or, we might make a mistake.

The quick and easy kaizen process works as follows:

- The employee notices a problem or an opportunity for improvement.

- The employee gets an improvement idea, writes it down and submits it to his or her supervisor.

- The employee implements the idea, writes up the idea on the Kaizen form and puts it into the Idea box.

- Within 24 hours, managers review and give positive feedback. A must!

- If a larger improvement idea is approved, the employee should take leadership to implement the idea. They just don’t submit an idea for someone else to implement.

- All implemented ideas should be posted to share with others.

- And praise, praise, praise!

Kaizen educates at the job site. Kaizen means knowing when to eliminate, reduce or change an activity. Kaizen promotes personal growth of employees and the company. Kaizen provides guidance for employees. Kaizen serves as a barometer of leadership. Kaizen does not conflict with productivity or quality efforts. Each kaizen is small, but the cumulative effect is tremendous. Fundamentally, there is just a resistance to change. But, kaizen is only small changes and can be done by the worker him or herself with very little investment of time.

Related Content

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More